Inconel 601 – Oxidation-Resistant Alloy for High-Temperature Applications

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Aerospace Industry: Used in jet engines, exhaust systems, and heat shields for high-temperature stability.

-

Chemical Processing: Ideal for reactors, heat exchangers, and furnace components exposed to aggressive environments.

-

Power Generation: Applied in boilers, superheater tubes, and gas turbine components.

-

Metallurgical Industry: Used in heat-treating equipment, radiant tubes, and retorts.

-

Pollution Control: Applied in incinerators, thermal oxidizers, and other waste processing systems.

-

ASTM B166 / ASME SB166: Covers nickel-chromium-iron alloy rods, bars, and wires.

-

ASTM B168 / ASME SB168: Covers plates, sheets, and strips of Inconel 601.

-

ASTM B167 / ASME SB167: Covers seamless pipes and tubes.

-

UNS N06601: The unified numbering system (UNS) designation for Inconel 601.

-

Melting and Alloying: The raw materials are melted in vacuum or electric arc furnaces to achieve the precise chemical composition.

-

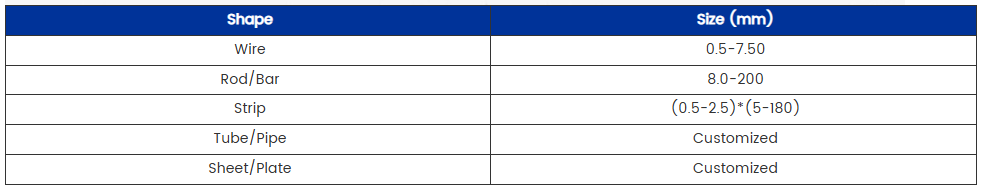

Hot and Cold Working: The alloy is processed through rolling, forging, and extrusion to achieve the required shapes and dimensions.

-

Heat Treatment: Solution annealing enhances mechanical properties and oxidation resistance.

-

Machining and Finishing: Precision machining, grinding, and polishing improve surface quality and dimensional accuracy.

-

Testing and Quality Control: The alloy undergoes rigorous testing, including mechanical strength, oxidation resistance, and non-destructive testing (NDT).

-

Customization: Providing tailored sizes, shapes, and surface finishes.

-

Compliance with International Standards: Ensuring reliability and safety through stringent quality control.

-

High-Temperature and Corrosion Resistance: Guaranteeing superior performance in extreme environments.

-

Longevity and Strength: Reducing maintenance costs and enhancing operational efficiency.

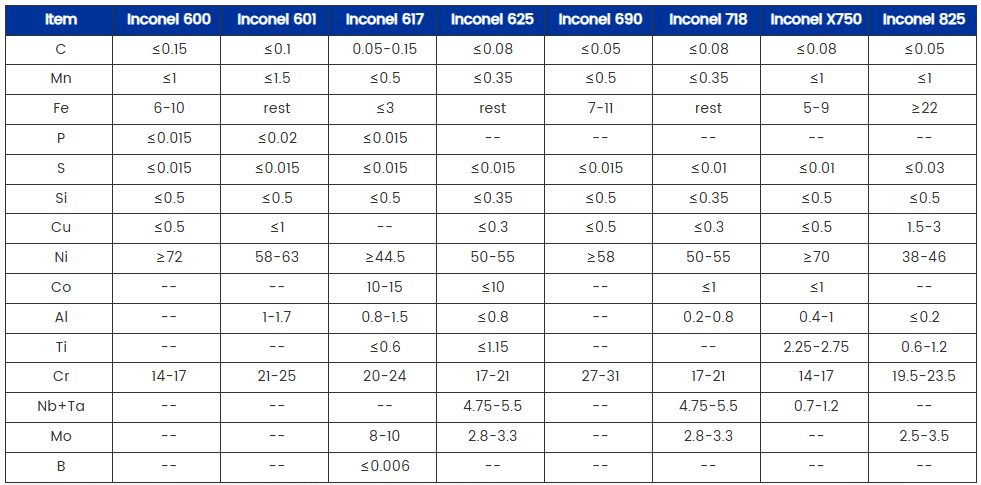

Inconel 601 is a high-performance nickel-chromium-iron alloy known for its exceptional oxidation resistance and high-temperature strength. This alloy is widely used in industries requiring materials that can withstand extreme thermal and corrosive conditions, making it an ideal choice for high-temperature applications.

Material Overview

Inconel 601 is composed primarily of nickel (58-63%), chromium (21-25%), and iron, with small amounts of aluminum and other elements. This composition provides outstanding oxidation resistance, superior mechanical properties, and excellent resistance to carburization and sulfidation. The alloy maintains its structural integrity even under prolonged exposure to elevated temperatures.

Applications

Due to its superior high-temperature and corrosion-resistant properties, Inconel 601 is used in various industries, including:

Grades and Specifications

Inconel 601 is available in various grades and specifications to meet industry requirements. Some common standards include:

These forms are available in different dimensions and finishes to suit diverse applications.

Manufacturing Process

The production of Inconel 601 involves several key steps to ensure high quality and performance:

Meeting User Demands

Manufacturers of Inconel 601 focus on delivering high-quality products that meet customer expectations by:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.