Beli Kabel Las ERNiCrMo-4 (C-276) untuk Pembangkit Listrik – Tarif Grosir Terbaik

Lebih banyak: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Kami menawarkan harga langsung dari pabrik dengan diskon khusus untuk pesanan grosir. Apakah Anda membutuhkan jumlah kecil atau besar, kawat las ERNiCrMo-4 kami tersedia untuk pengiriman segera, memastikan pasokan yang andal untuk proyek-proyek industri di seluruh dunia.

- Ikhtisar

- Aplikasi

- Pertanyaan yang Sering Diajukan

- Produk Rekomendasi

Pengenalan Kawat Las ERNiCrMo-4 (C-276)

ERNiCrMo-4 (C-276) kabel las, juga dikenal sebagai Hastelloy® C-276 kabel las, adalah paduan nikel berbasis tinggi yang dirancang untuk aplikasi pengelasan kritis di pembangkit listrik dan lingkungan industri lainnya. Paduan ini sangat dikenal karena ketahanannya terhadap korosi yang luar biasa, stabilitas pada suhu tinggi, dan kekuatan mekanis superior, menjadikannya bahan penting untuk boiler, penukar panas, turbin, dan tangki tekanan di fasilitas pembangkit listrik.

Sebagai pemasok terpercaya, kami menawarkan kabel las ERNiCrMo-4 langsung dari pabrik dengan harga grosir terbaik, memastikan solusi pengelasan berkualitas tinggi dengan opsi pengiriman internasional.

Ikhtisar Material: Sifat ERNiCrMo-4 (C-276)

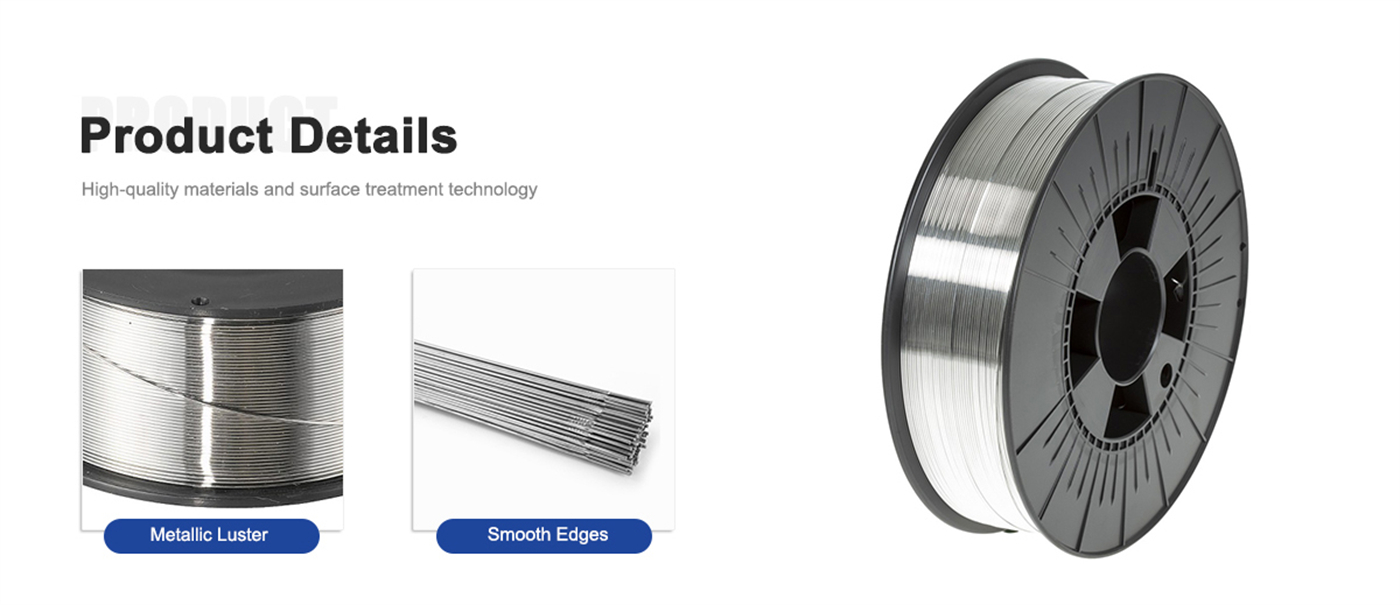

ERNiCrMo-4 adalah paduan nikel-kromium-molibdenum canggih dengan tambahan besi dan wolfram, yang meningkatkan ketahanannya terhadap lingkungan ekstrem. Kabel las ini dirancang khusus untuk menyatukan paduan berbasis nikel, baja tahan karat, dan logam tahan korosi lainnya, memastikan kinerja tinggi dan keandalan jangka panjang.

Fitur Utama Kawat Las ERNiCrMo-4 (C-276)

✔ Ketahanan Korosi Superior – Tahan terhadap lingkungan asam, oksidatif, dan kaya klorida dalam operasi pembangkit listrik.

✔ Kekuatan pada Suhu Tinggi – Menjaga integritas mekanis hingga 1093°C (2000°F).

✔ Kelasitas Las yang Unggul – Meminimalkan retak panas dan porositas, memastikan las yang kuat dan bebas cacat.

✔ Ketahanan Kimia – Memberikan perlindungan terhadap asam klorida, belerang, dan nitrat.

✔ Umur Penggunaan Panjang – Memastikan keawetan dan keandalan dalam lingkungan tegangan tinggi.

Sifat-sifat ini membuat kawat las ERNiCrMo-4 menjadi pilihan terbaik untuk aplikasi pembangkit listrik yang memerlukan solusi pengelasan berkinerja tinggi.

Standar Industri & Spesifikasi

Kawat las ERNiCrMo-4 kami memenuhi standar industri global, menjamin kompatibilitasnya dengan peralatan dan sistem pembangkit listrik.

Spesifikasi Standar

AWS A5.14 ERNiCrMo-4

Nomor UNS N10276

Standar ASTM ASTM B574, ASTM B575

Standar ISO ISO 18274: NiCr15Mo16Fe6W4

Sertifikasi ini menjamin kinerja berkualitas tinggi, keselamatan, dan keawetan dalam aplikasi pembangkit tenaga.

Aplikasi Kawat Las ERNiCrMo-4 (C-276) di Pembangkit Listrik

1. Ketel & Turbin Uap

Pembangkit listrik membutuhkan material las yang tahan suhu tinggi untuk ketel, turbin uap, dan penukar panas. ERNiCrMo-4 menyediakan:

Perlindungan terhadap oksidasi dan stres termal pada sistem pembuatan uap.

Ketahanan jangka panjang dalam kondisi panas ekstrem.

2. Penukar Panas & Vessel Tekanan

Penukar panas dan vessel tekanan di pembangkit listrik menangani fluida bertekanan tinggi dan suhu tinggi. ERNiCrMo-4 memastikan:

Ketahanan korosi terhadap lingkungan kimia agresif.

Sambungan las yang kedap bocor dan kuat untuk umur operasional yang lebih lama.

3. Sistem Desulfurisasi Gas Buang (FGD)

Pabrik pembangkit listrik menggunakan sistem FGD untuk mengurangi emisi dioksida sulfur (SO₂), memerlukan material yang tahan terhadap lingkungan asam dan kaya klorida. ERNiCrMo-4 sangat ideal karena:

Mencegah korosi dari gas asam dan air limbah.

Menjaga integritas struktural dalam kondisi kimia ekstrem.

4. Pembangkit Listrik Tenaga Nuklir

Di fasilitas energi nuklir, material harus mampu menahan radiasi, panas, dan pendingin korosif. ERNiCrMo-4 digunakan dalam:

Sistem pendinginan primer dan sekunder.

Pipa reaktor nuklir dan struktur penyimpanan.

5. Fasilitas Energi Terbarukan

Dengan pertumbuhan pembangkit listrik tenaga surya, angin, dan panas bumi, ERNiCrMo-4 semakin banyak digunakan untuk:

Mengelas pipa pembangkit listrik panas bumi yang terpapar cairan panas bumi asam.

Komponen struktural di farm turbin angin lepas pantai, tahan terhadap korosi air laut.

Mengapa Memilih Kabel Las ERNiCrMo-4 (C-276) Kami?

✅ Harga Grosir Terbaik – Diskon khusus untuk pesanan dalam jumlah besar.

✅ Pasokan Langsung dari Pabrik – Jaminan kawat las berkualitas tinggi dengan harga pabrik.

✅ Pengiriman Internasional – Pengiriman global yang andal untuk proyek pembangkit listrik di seluruh dunia.

✅ Bahan Berkualitas Tinggi Bersertifikat – Memenuhi standar industri AWS, ASTM, dan ISO.

✅ Kemasan dan Ukuran Kustom – Tersedia dalam gulungan, kumparan, dan panjang potongan kustom.

✅ Ketersediaan Stok Terjamin – Siap untuk pengiriman segera.

Pesan Kabel Las ERNiCrMo-4 (C-276) Hari Ini – Dapatkan Harga Grosir Terbaik!

Mencari kabel las ERNiCrMo-4 dengan kualitas premium pada harga langsung dari pabrik? Kami menawarkan penawaran pembelian grosir, pengiriman internasional cepat, dan opsi pesanan yang disesuaikan untuk memenuhi kebutuhan pembangkit listrik dan fasilitas industri di seluruh dunia.

Pertanyaan umum:

Berapa lama waktu pengiriman?

Tergantung pada jumlah pesanan, 10-30 hari untuk pesanan kecil. Untuk pesanan besar, membutuhkan waktu 60 hari.

Apakah Anda menerima produksi OEM/ODM?

Ya! Kami menerima produksi OEM/ODM. Anda bisa mengirimkan sampel atau gambar kepada kami.

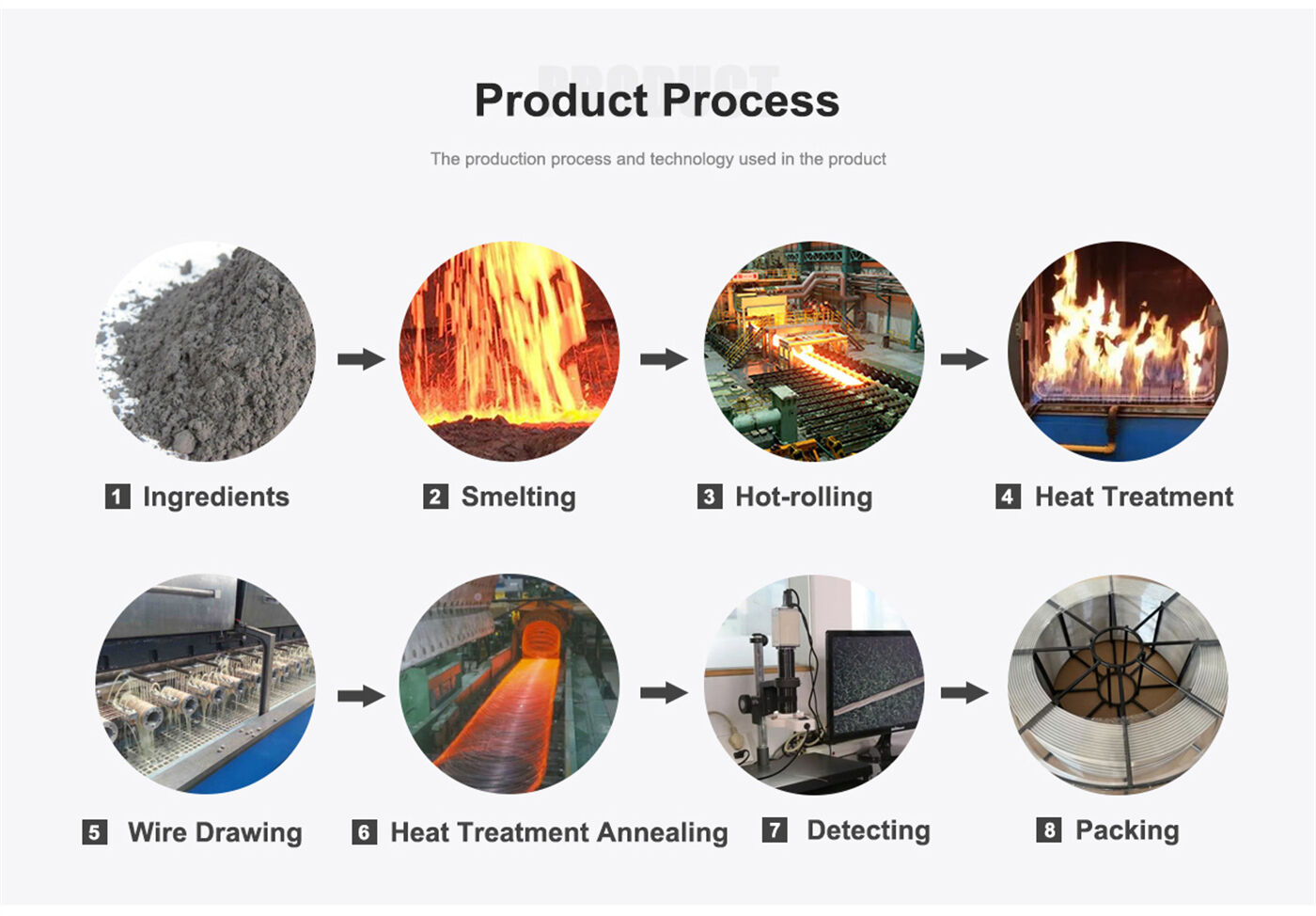

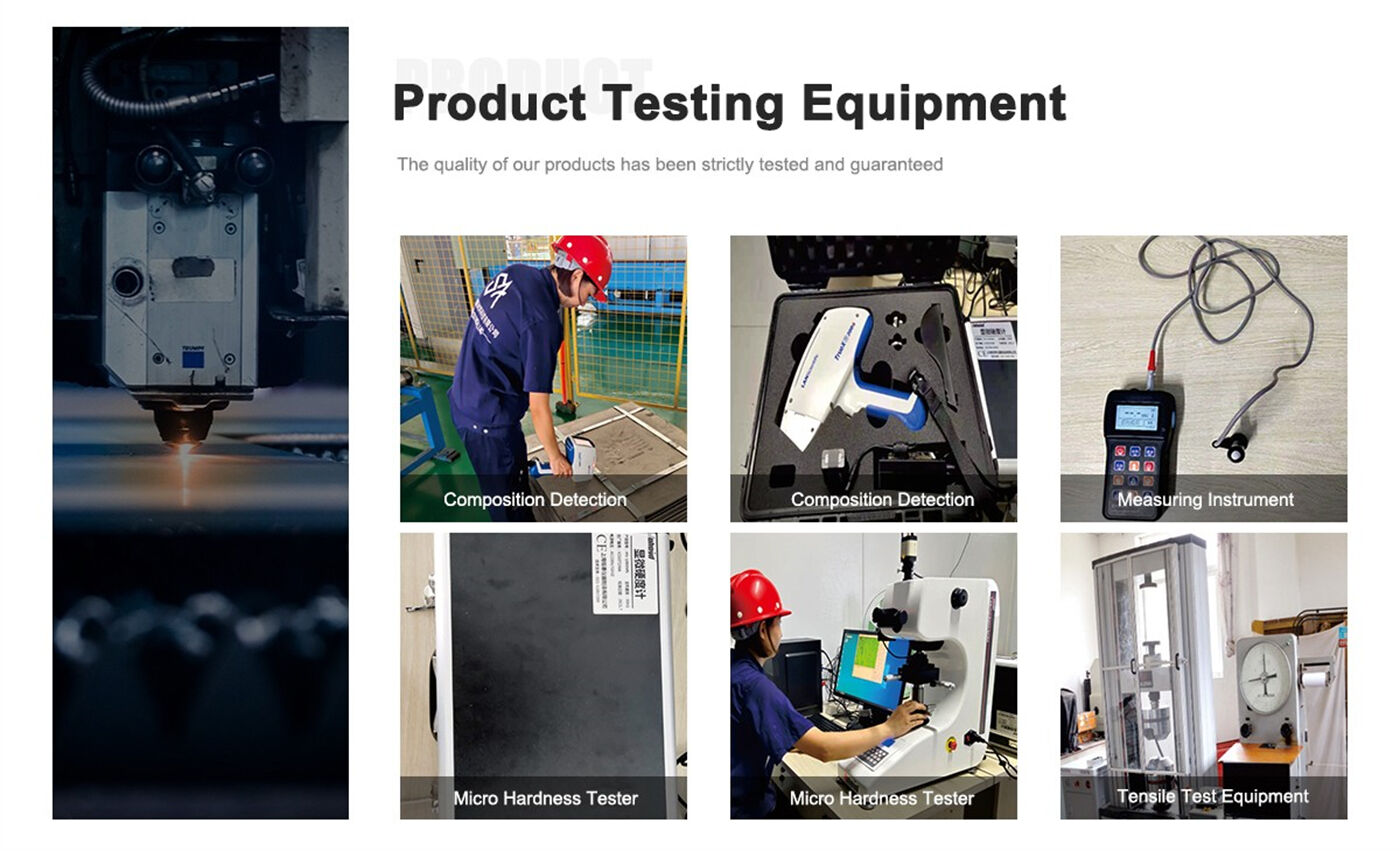

Bagaimana Anda mengontrol kualitas produk Anda? Apakah sifat kimia produk-produk tersebut memenuhi standar kualitas?

Dengan tim kualitas profesional, perencanaan kualitas produk canggih, pelaksanaan ketat, dan peningkatan berkelanjutan, kami akan menerbitkan sertifikat pemeriksaan kualitas produk, termasuk laporan analisis kimia.

Apakah perusahaan Anda dapat menyediakan data teknis dan gambar rinci?

Ya, Anda bisa. Silakan beri tahu kami produk dan aplikasi yang Anda butuhkan, dan kami akan mengirimkan data teknis dan gambar rinci untuk evaluasi dan konfirmasi Anda.

Bagaimana Anda menangani layanan pra-penjualan dan pasca-penjualan?

Kami memiliki tim bisnis profesional yang akan bekerja satu-satu untuk melindungi kebutuhan produk Anda, dan jika Anda memiliki pertanyaan, dia dapat menjawabnya untuk Anda!

Bisakah saya mengunjungi pabrik Anda sebelum memasang pesanan?

Ya, Anda dipersilakan untuk mengunjungi pabrik kami. Kami senang memiliki kesempatan untuk saling mengenal.

Dimana lokasi basis produksi Anda?

Kami memproduksi produk di Jiangsu, Cina dan mengirimkannya dari Cina ke negara Anda secepat mungkin, yang biasanya tergantung pada persyaratan produk dan kuantitasnya.

Bisakah kau kirim sampel?

Ya, kita bisa.