N4 Nikkel Elektroda Dűt 1.2mm-3.2mm | TIG & MIG Ütemezéshez Legjobb

Gyári árral és különleges kedvezményekkel kínáljuk a nagy mennyiségű rendeléseket. Kisebb vagy nagyobb mennyiségben, a termékeink gyorsan szállításra kerülnek, hogy megbízható ellátást biztosítson ipari projektek számára világszerte.

- Áttekintés

- Specifikáció

- Alkalmazások

- Gyakran Ismételt Kérdések

- Ajánlott termékek

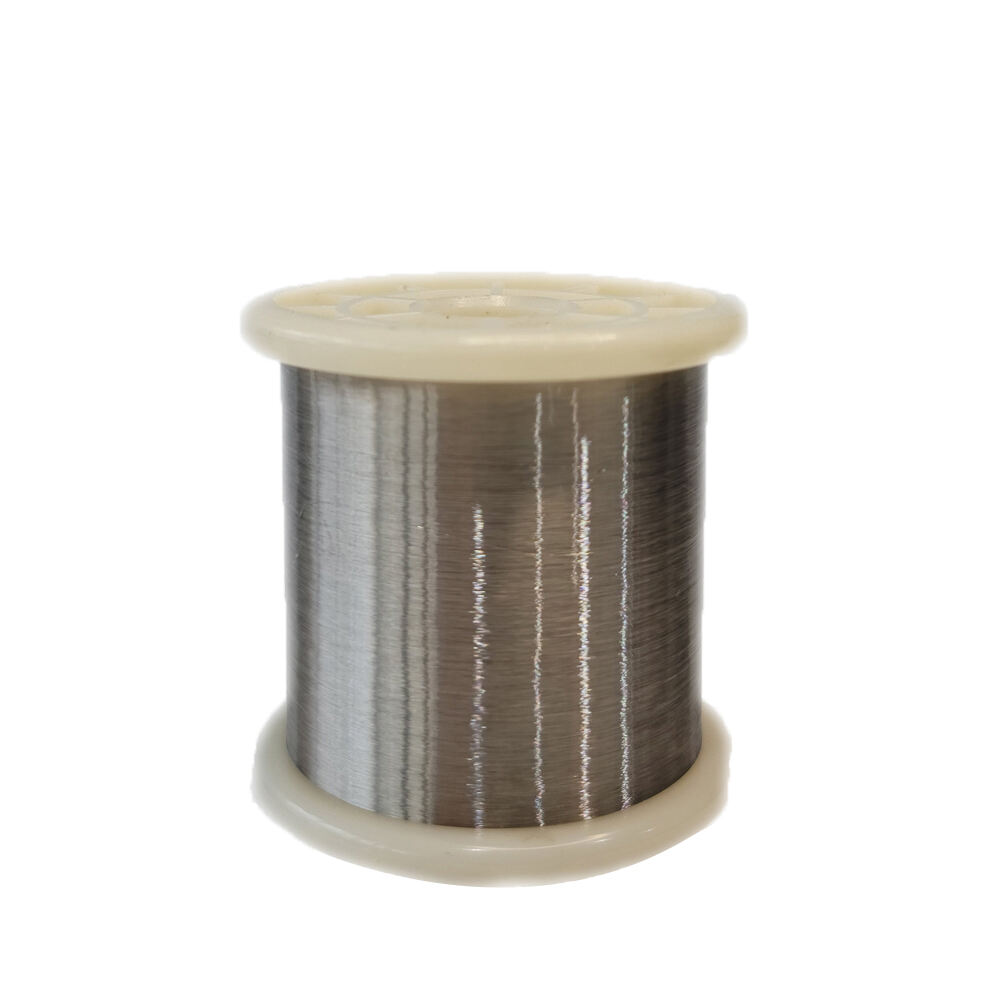

Bevezetés az N4 nikkel elektrod-szálba

Az N4 Nikkel Elektrod-szál magas fokú nikkeltartalmú (≥99,9% Ni) vízszintesítő szál, amelyet TIG (Tungsten Inert Gas) és MIG (Metal Inert Gas) vízszintesítési alkalmazásokra terveztek. 1,2mm-től 3,2mm-ig terjedő átmérőkkel ez a vízszintesítő szál kiváló korrozió-ellenállást, hőstabilitást és kiemelkedő vízszintesíthetőséget biztosít, ami teszi alkalmasnak a kémiai, tengerészeti és magas hőmérsékletű iparágakban fellépő exigeens vízszintesítési feladatokhoz.

Az N4 nikkel elektrod-szál gyakran használnak tisztánikkel, nikkel-liga és különböző fémtípusok összekapcsolására, erős, rugalmas és oxidáció ellenálló vízszintesítményeket nyújtva. Kiváló választás a nikkelszerelésű hőcserélők, nyomásvesszők és ipari csövek vízszintesítésére.

Az N4 Nikkel Elektrod-szál kulcsfontosságú jellemzői

✔ Magas nikkel-tisztaság (≥99,9%) – Garantálja a kiváló korroziónyugtatlanságot és oxidációs ellenállást.

✔ Optimalizálva a TIG & MIG vízszintesítéshez – Erős és zúzlódás ellenálló vízszintesítményeket biztosít.

✔ Kiváló hővezetékenység – Keresztül bír a magas-hőmérsékletű vízszintes összefonás környezetekkel.

✔ Alacsony szórás & Sima ívstabilitás – Tisztességes és hatékony összefonás műveleteket biztosít.

✔ Kiváló sav- és bázis ellenállás – Tengerszállítmányi, kémiai és erőmű alkalmazásokhoz alkalmas.

N4 Nikkel Fonalak Alkalmazásai

1. TIG és MIG fonás nikkelen és nikkelszövedgeken

Alkalmazható a nikkelfejlesztésű komponensek pontosságos összefonására.

Használatos hőcserélőkben, kémiai feldolgozó berendezésekben és erőművekben.

Magas minőségű, rugalmas és oxidáció ellenálló összefonásokat biztosít.

2. Magas hőmérsékletű és rovaros környezetek

Tengerszállítmányi, petrokémiai és repülészeti iparágak számára ideális.

Használják a tüzékes tárolók, nyomásvesszők és áramvonalak összefűzésére, amelyek savos és bázisos oldatok hatására vannak kitettetve.

Hosszú tartós rugalmasságot kínál Nehézipari környezetek között.

3. Különböző Fémek Összefűzése

Alkalmas nikkel és rostmentes acél, réz-ligavak valamint más fémtípusok összekapcsolására.

Gyakran használnak elektrokémiai iparágakban és magas hőmérsékletű szerkezeti komponensekben.

Erős, megbízható és korroziónyugtató összefűzéseket biztosít.

4. Energiaiparos Termelés & Energiagyártás

Használják a nukleáris reaktorokban, gőzgenerátorokban és ipari gőzhordozókban.

Kiváló teljesítményt biztosít extrém hőmérséklet és sugárzás hatására.

Biztosítja a biztonságos és stabil összefűzést az energiaátviteli komponensek számára.

Műszaki adatok az N4 nikkel elektromos vezetékről

Specifikáció részletei

Anyag N4 Tisztánikkel (≥99,9%)

Átmérő 1,2mm - 3,2mm

Szabványosítás ASTM B160, GB/T 2072-2007

Fuszonpont 1455°C (2651°F)

Húzóerő ≥380 MPa

Miért választania kell az N4 nikkel elektromos vezetékünket?

Gyárától való közvetlen ellátás és nagykereskedelmi kedvezmények

Magas tisztaságú nikkel javított üvöltési teljesítménnyel

Különböző átmérőkben elérhető (1,2mm - 3,2mm)

Gyors nemzetközi szállítás és OEM testreszabás

GYIK:

Mennyi idő alatt szállítjuk?

Az rendelés mennyiségétől függ, kis rendelések esetén 10-30 nap. Nagy rendelések esetén 60 napot vesz igénybe.

Elfogadnak OEM/ODM termelést?

Igen! Elfogadjuk az OEM/ODM termelést. Elküldheti nekünk az mintáit vagy rajzait.

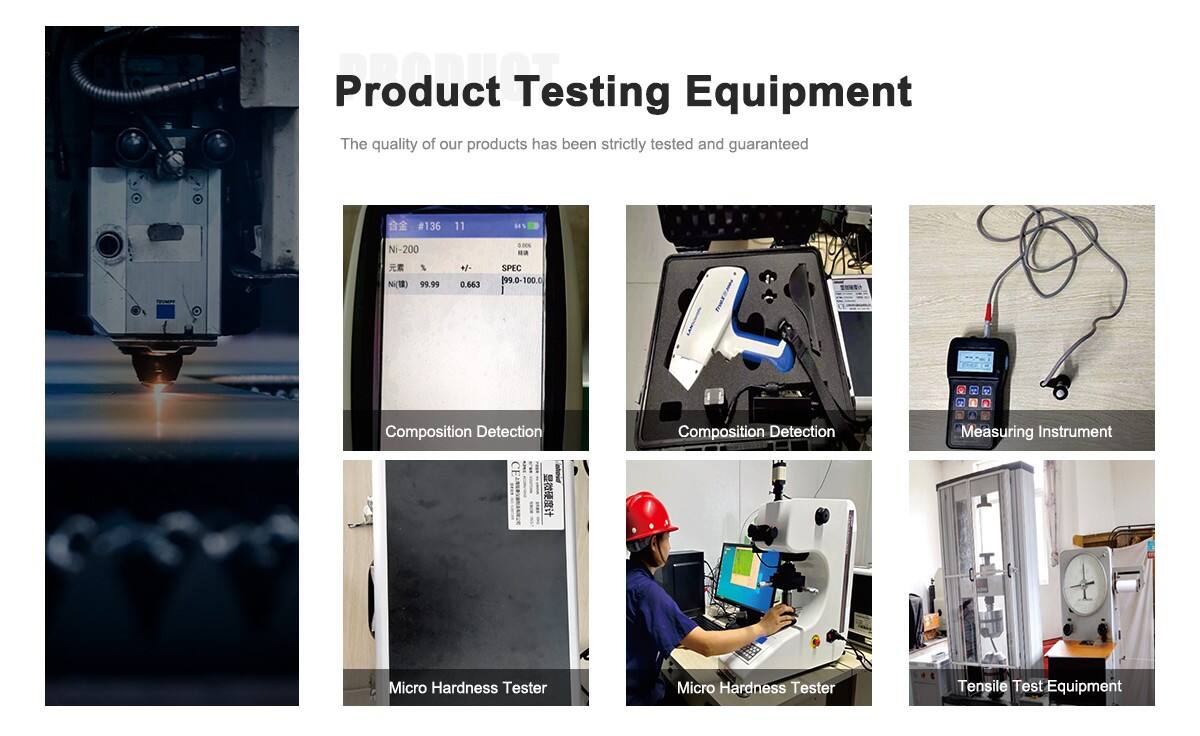

Hogyan ellenőrizzük a termékek minőségét? A termékek kémiai tulajdonságai megfelelnek-e a minőségi szabványoknak?

Professzionális minőségbiztosítási csapatunkkal, haladó termékminőségi tervezéssel, szigorú végrehajtás és folyamatos fejlesztéssel kiállítunk termékminőségi ellenőrzési tanúsítványt, beleértve a kémiai elemzési jelentést is.

Közzéteheti a részletes technikai adatokat és rajzokat?

Igen, megteheti. Kérjük, osszon meg velünk a szükséges termékeket és alkalmazásokat, és küldjük el Önnek a részletes technikai adatokat és rajzokat értékelésre és megerősítésre.

Hogyan kezelik az előzetes és utánvizsgálati szolgáltatást?

Professzionális üzleti csapatom van, amely egyenes vonalban fog dolgozni Önél, hogy védekezze meg a termékigényeit, és ha bármilyen kérdése lenne, ő válaszol rá!

Látogathatok a gyárodon, mielőtt rendelést bocsátok?

Igen, üdvözlünk, ha megvizsgálja gyárunkat. Örülünk annak, hogy megismerhetjük egymást.

Hol található a termelési bázisotok?

A termékeket Kínában, Jiaoszuszbán gyártjuk és minél hamarabb Kínából szállítjuk az országodba, ami általában attól függ, milyen termékkövetelményeked vannak és milyen mennyiségben.

Küldhetsz mintákat?

Igen, tudunk.