Melegterjesztési Hastelloy C-4 Lapok – Kiváló magas hőmérsékletű alkalmazásokhoz

Gyári árral és különleges kedvezményekkel kínáljuk a nagy mennyiségű rendeléseket. Kisebb vagy nagyobb mennyiségben, a termékeink gyorsan szállításra kerülnek, hogy megbízható ellátást biztosítson ipari projektek számára világszerte.

- Áttekintés

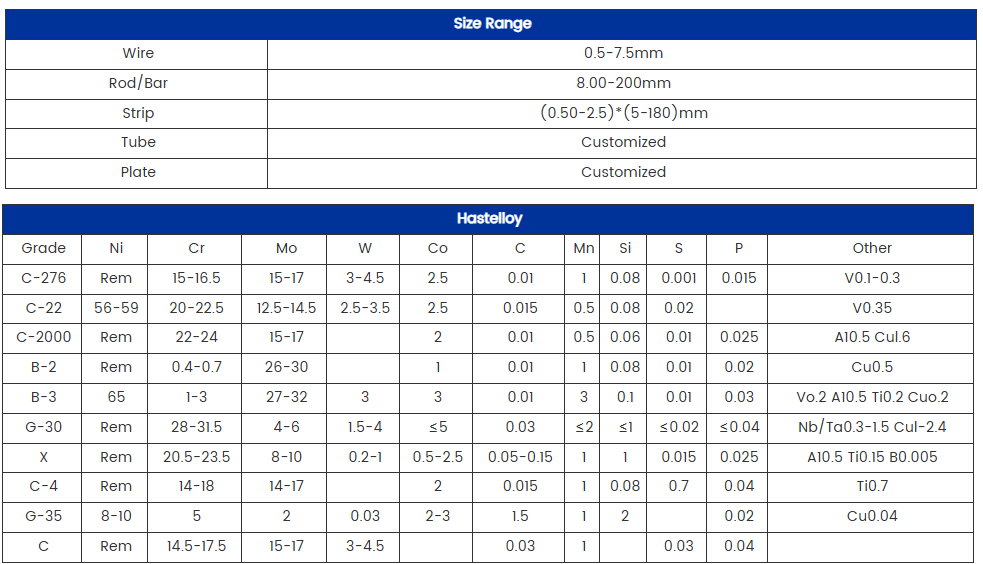

- Specifikáció

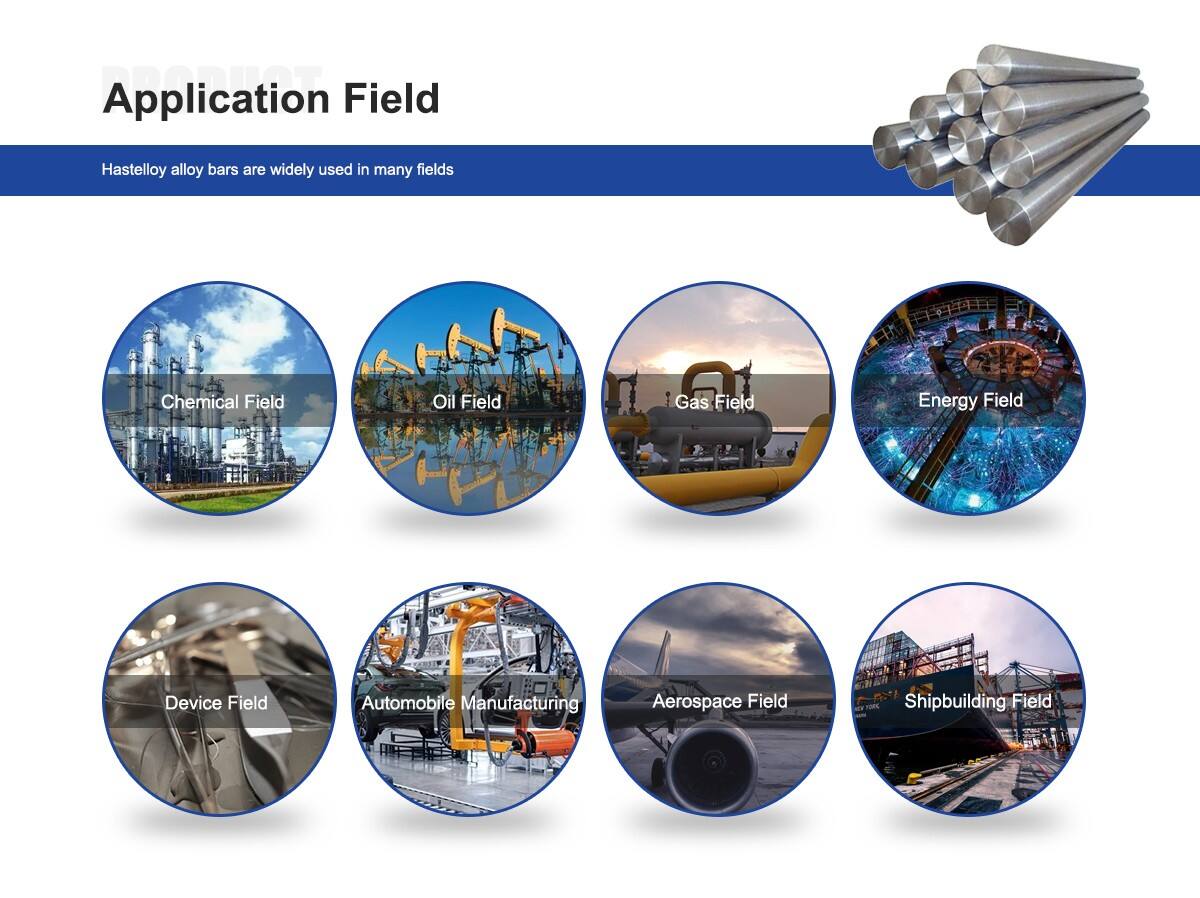

- Alkalmazások

- Gyakran Ismételt Kérdések

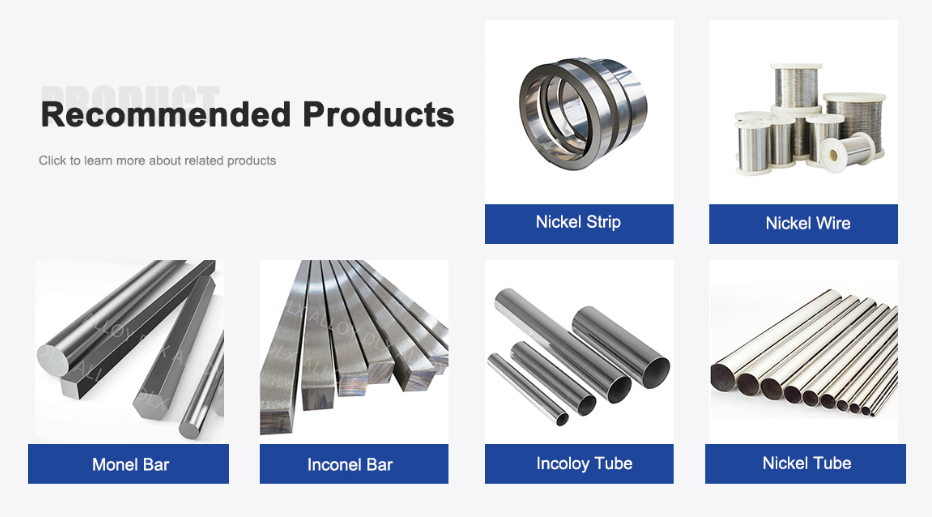

- Ajánlott termékek

-

Kiváló hőellenállás: magas hőmérsékleten is fenntartja a mechanikai erősséget és a rovarugrás elleni ellenállást.

-

Első osztályú rovarugrás-ellenállás: meg tud állni az oxidációnak, a karburizációnak és a tömeges rovarugrásnak.

-

Magas szerkezeti integritás: kiváló összefonhatóságot és alakíthatóságot kínál bonyolult gyártási igényekhez.

-

Kémiai stabilitás: jól teljesíti magas savas és oxidációs környezetekben.

-

Kémiai feldolgozó ipar: hasznosítják reaktorokban, hőcserélőkben és nyomás tárolókban, amelyek extrém hőmérsékleteket és rovarugrós anyagokat kezelnek.

-

Repülészár és energiaállomány: alkalmazásuk van turbinasz komponensekben, kiforduló rendszerekben és magas hőmérsékletű szerkezeti elemekben.

-

Magyar energiaszektor: alkalmazásuk van a nukleáris üzemanyag-feldolgozásban és a hővédőkben, következtében a ráció- és hőellenállásuk miatt.

-

Gyógyszerészi és élelmiszeripar: alkalmas eszközök gyártására, amelyek sterillítésre vagy agresszív tisztítóügynökökre vannak kitéve.

-

Füstgáz-széndioxid-távolítási rendszerek: Lényegesek a szennyezés-ellenes alkalmazásokban elektromos áramtermelőkben és ipari településekben.

-

UNS szám: N06455

-

ASTM Szabványok: ASTM B575 (Lapok és Lapok), ASTM B619/B622 (Csövek & Csomópontok)

-

EN/DIN Ekvivalens: 2.4610

-

Öntés és ötvözés: Az anyagok vakuum-indukciós öntésen (VIM) vagy villamos hajtómű-ben (EAF) keresztül feldolgoznak.

-

Gurítás és alakítás: Forró és hideg gurítási technikák pontos lapvastagságokra finomítják az anyagot.

-

Hőbejárás (annealing): Növeli a nyúlhatóságot és a rovarmentesítést, miközben stabilizálja a szerkezetet.

-

Felszín-feldolgozás: Belefoglalja a savítást és a passziválást egy tisztán, oxidáció ellenálló felszínt elérni érdekében.

-

Minőségbiztosítás: Gépi, kémiai és hőmérsékleti tesztek ellenőrzik a szektori szabványoknak való megfelelését.

-

Egyedi méretek: Lapok különböző vastagságokban és szélességekben érhetők el konkrét alkalmazásokhoz.

-

Felszínűsítési lehetőségek: Gépeléses felszín, pólvillanyozott vagy fedőanyaggal ellátott a teljesítmény növelése érdekében.

-

Állványozás és gépelés: Biztosítja a kompatibilitást a fonálás, vágás és alakítás folyamataival.

-

Igazságszerűség az ipari szabványokkal: A anyagoknak meg kell felelniük az ASTM, ASME és más szabályozási követelményeknek.

A Hastelloy C-4 egy nikkelalapú szuperhõanyag, amely kiválóan alkalmas a magas hőmérsékletek és agresszív kémiai környezetek elleni ellenállásra. Lapokká alakítva ez a anyag biztosítja a nagy tartóságot és stabilitást, ami teszi ideálisnak azokban az iparágakban, amelyek extrém feltételek között működnek.

Az anyag összetétele és tulajdonságai

A Hastelloy C-4 magas arányú nikkelből áll, amely molybdén és cróm kombinációval javítja a teljesítményét a magas hőmérsékletű alkalmazásokban. A legfontosabb jellemzők közé tartoznak:

Hastelloy C-4 Lapok alkalmazásai

Kiváló hő- és korrozióellenálló tulajdonságai miatt a Hastelloy C-4 lapok széleskörűen használni az iparban, beleértve:

Fajták és Szabványok

A Hastelloy C-4 több nemzetközi szabvánnyal is elismert, amely biztosítja alkalmazhatóságát különféle iparágakban:

Gyártási folyamat

A Hastelloy C-4 táblák gyártása szigorú folyamatot követ, hogy biztosítsa a minőséget és megbízhatóságot:

Felhasználói igények és testreszabás

A Hastelloy C-4 táblákat használó iparágak gyakran személyre szabott megoldásokat igényelnek. A gyakori specifikációk közé tartoznak:

GYIK:

Mennyi idő alatt szállítjuk?

Az rendelés mennyiségétől függ, kis rendelések esetén 10-30 nap. Nagy rendelések esetén 60 napot vesz igénybe.

Elfogadnak OEM/ODM termelést?

Igen! Elfogadjuk az OEM/ODM termelést. Elküldheti nekünk az mintáit vagy rajzait.

Hogyan ellenőrizzük a termékek minőségét? A termékek kémiai tulajdonságai megfelelnek-e a minőségi szabványoknak?

Professzionális minőségbiztosítási csapatunkkal, haladó termékminőségi tervezéssel, szigorú végrehajtás és folyamatos fejlesztéssel kiállítunk termékminőségi ellenőrzési tanúsítványt, beleértve a kémiai elemzési jelentést is.

Közzéteheti a részletes technikai adatokat és rajzokat?

Igen, megteheti. Kérjük, osszon meg velünk a szükséges termékeket és alkalmazásokat, és küldjük el Önnek a részletes technikai adatokat és rajzokat értékelésre és megerősítésre.

Hogyan kezelik az előzetes és utánvizsgálati szolgáltatást?

Professzionális üzleti csapatom van, amely egyenes vonalban fog dolgozni Önél, hogy védekezze meg a termékigényeit, és ha bármilyen kérdése lenne, ő válaszol rá!

Látogathatok a gyárodon, mielőtt rendelést bocsátok?

Igen, üdvözlünk, ha megvizsgálja gyárunkat. Örülünk annak, hogy megismerhetjük egymást.

Hol található a termelési bázisotok?

A termékeket Kínában, Jiaoszuszbán gyártjuk és minél hamarabb Kínából szállítjuk az országodba, ami általában attól függ, milyen termékkövetelményeked vannak és milyen mennyiségben.

Küldhetsz mintákat?

Igen, tudunk.