Vásárolj ERNiCrMo-4 (C-276) Üvöltőszál nagy mennyiségben – Garantált alacsony ár

- Áttekintés

- Ajánlott termékek

Bevezetés az ERNiCrMo-4 (C-276) svárkötőtényezőbe

Az ERNiCrMo-4 (C-276) divatgyűrű nikkel-krom-molibdénus ötvözettel rendelkező anyag, amely magas teljesítményű divatolási alkalmazásokra van terveztve korrosív, magas nyomású és magas hőmérsékletű környezetekben. Kiváló korrozióellenállással, kiemelkedő mechanikai erősséggel és egyaránt kitűnő divatolhatósággal, ez a divatgyűrű széleskörűen használatos az olaj- és gáziparban, a kémiai feldolgozó iparban, a villamosenergia termelésében, az űrhajóiparban és a tengerészeti mérnöki területen.

Kereskedelmi mennyiségben kínáljuk az ERNiCrMo-4 típusú vízszálakat gyártási áron, magas minőségű, költséghatékony megoldásokkal az ipari vízszálás projektek számára. Kereskedelmi kedvezményekkel, testreszabott csomagolással és gyors szállítással megbízható partnert választottunk minden vízszálási igényre.

Anyag áttekintése: Az ERNiCrMo-4 (C-276) összefonódrót tulajdonságai

Az ERNiCrMo-4 (C-276), más néven Hastelloy® C-276, kiváló teljesítményt nyújt bonyolult alkalmazásokban, köszönhetően a kiemelkedő anyagtulajdonságainak:

✔ Kiváló korróziós ellenállás – Előtérben marad a pottyás, szivacsos korrózió és a tömeges korrosziós törés elleni védekezés az avasztató-, klórf tartalmú és magas-szénioxid-köppen környezetekben.

✔ Magas hőmérsékletű stabilitás – Fenntartja a strukturális integritást 1093°C (2000°F) hőmérsékletig.

✔ Kiváló összefonódhatóság – Tisztességes, erős és hibátlan összefonásokat biztosít minimális forró törésekkel.

✔ Áldozatos kémiai anyagok elleni ellenállás – Ideális kémiai gyárakban, rafinériumokban és offshore platformokon.

✔ Nagy erősség és hosszú tartóság – Kiemelkedő nyomás- és stressztűrés a szélső környezetekben.

Ezek a tulajdonságok teszik az ERNiCrMo-4 vízszálakat kedvelt választásnak a korrosziós ellenálló hõanyagok vízszálásához az ipari szektorokban.

Ipari szabványok és specifikációk

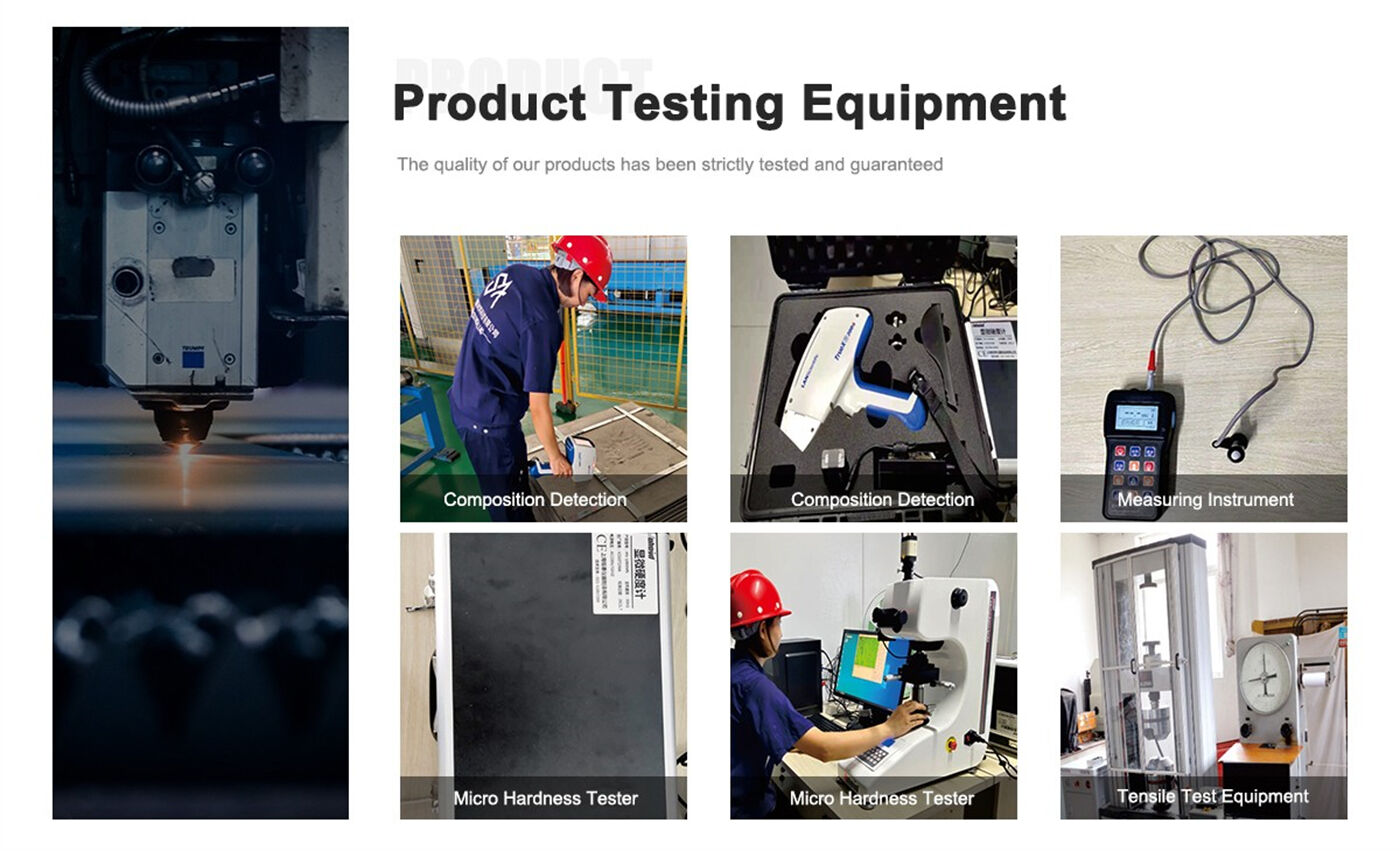

Az ERNiCrMo-4 (C-276) vízszálaink nemzetközi minőségi szabványoknak felelnek meg, amelyek biztosítják a kiemelkedő teljesítményt és megbízhatóságot.

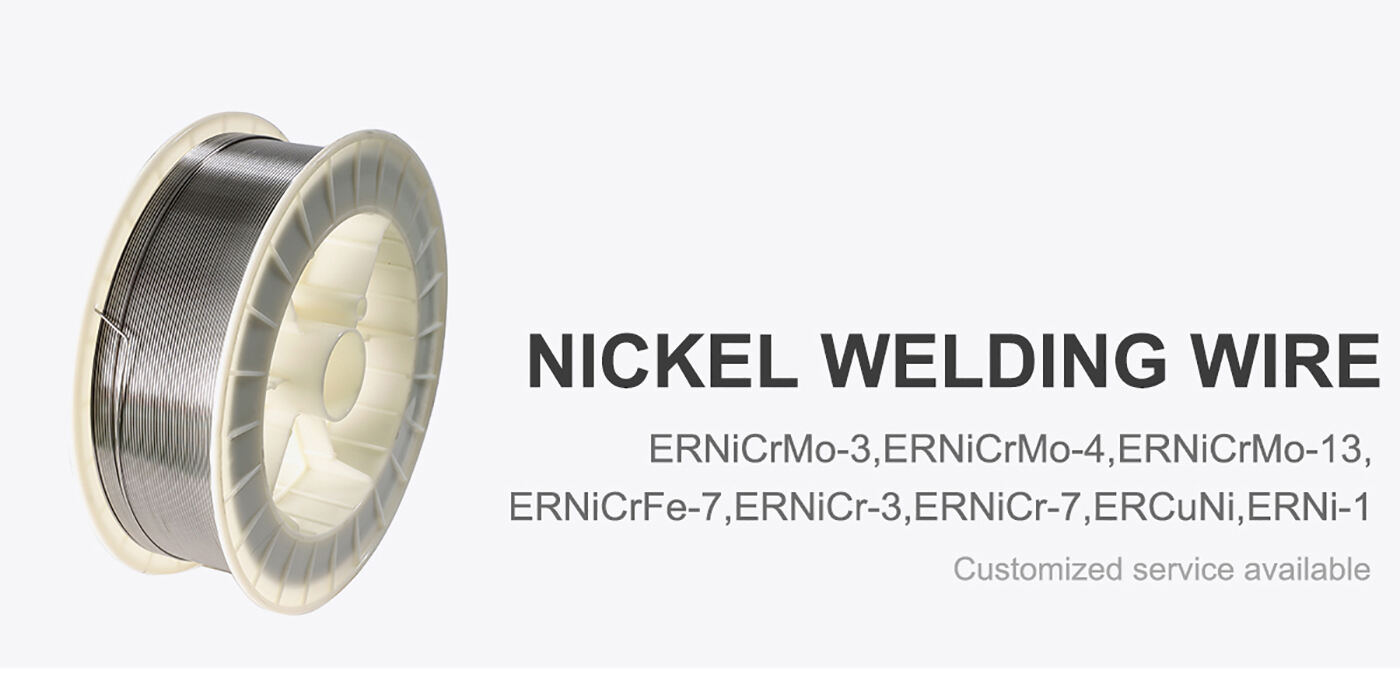

Vízszálási sorozat:

ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7, ERNi-1, ER70S-6.

Szabvány: Megfelel a tanúsítványnak: AWS A5.14 ASME SFA A5.14

Méret: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

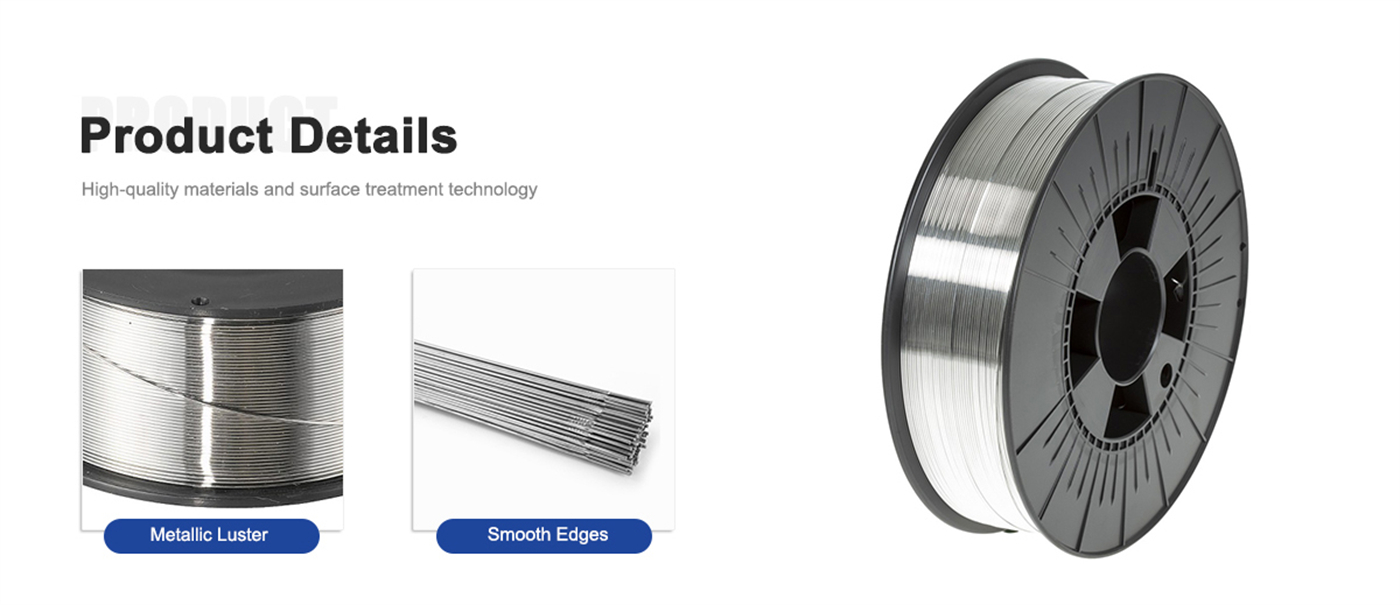

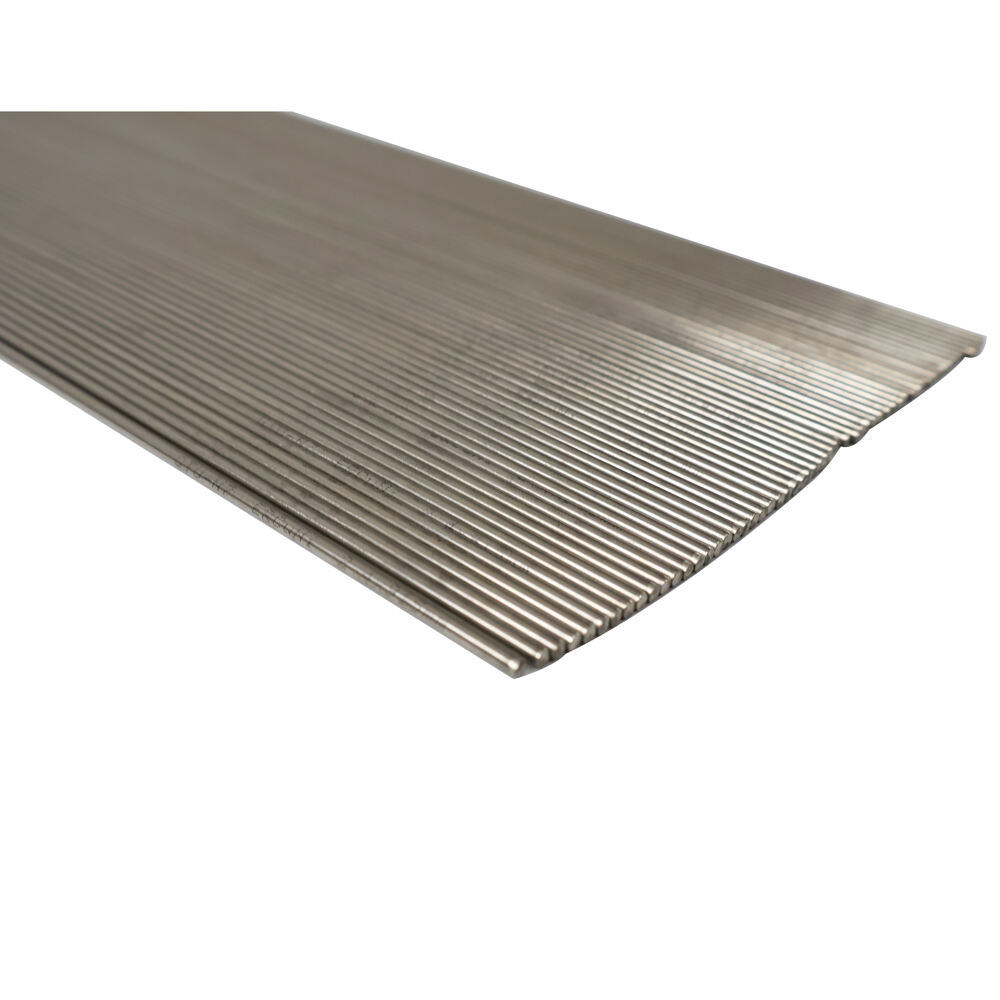

Forma: MIG(15kgs/csomópont), TIG(5kgs/doboz), Lépés

Szabványos specifikáció

AWS A5.14 ERNiCrMo-4

UNS szám N10276

ASTM szabvány ASTM B574, ASTM B575

ISO szabvány ISO 18274: NiCr15Mo16Fe6W4

Ezek a tanúsítványok biztosítják, hogy a vízszálunk megfelel a legszigorúbb ipari követelményeknek a kritikus komponensek összefonása során magas kockázatú környezetekben.

ERNiCrMo-4 (C-276) vízjel-welding drótvonal alkalmazásai

1. Olaj- és gázipart

Csövek összefonása – Éles légkörökben sulfídszivárványtól és hidrogénromlástól való védelem.

Tengeri platformok és alvízi készülékek – Tűrhetik a tengerszénhidrogén fénymérleges korózióját és az extrém nyomási feltételeket.

Raffináló műszeresek – Használnak hőcseregekben, reaktorokban és nyersolaj destillációs egységekben.

2. Kémiai feldolgozó üzemek

Avasz tárolók és csövek – Koróziós ellenálló szulfúros, hydrochloric és nitrik avasz környezetekben.

Hőcseregek és nyomásvesszők – Biztosítja a tartóságot magas nyomású, magas hőmérsékletű műveletekben.

3. Energiaművezetés és nukleáris ipar

Nukleáris reaktor komponensek – Fenntartja a sugárzás- és koróziós ellenállást a nukleáris erőművekben.

Gáz- és párturbínák – Nyújt oxidáció elleni védelmet magas hőmérsékletű feltételek között.

4. Repülészeti és Tengerészeti Mérnöki Szakterület

Repülőgép motoros részek – Ideális repülőgép motorkomponensekhez és magas hőmérsékletű kifutási rendszerekhez.

Hajóépítés és tengeri vízi rendszerek – Elővédi a korróziót tengeri és mélytengeri alkalmazásokban.

5. Élelmiszer- és gyógyszergyártó ipar

Higiéniai csövek és feldolgozó berendezések – Biztosítja a higienikus és kontaminációmentes összavasítást.

Sterilizáló berendezések – Magas korróziós ellenállást biztosít orvosi és élelmiszeripari alkalmazásokban.

Miért választania kell az ERNiCrMo-4 (C-276) összavaró drótjainkat?

Gyár árak nagykereskedelmi beszerzésre – Garantált alacsony ár nagyméretű rendelésekre és nagykereskedelmi vásárlásokra.

Minőségben tanúsított allow – Megfelel az AWS, ASTM és ISO ipari szabványoknak.

Egyéni méretek és csomagolás – Részekben, gyűrűkben és vágott hosszúságokban érhető el.

Gyors és megbízható globális szállítás – Gyors kiszállítás világszerte a vásárlóknak.

Állandó készlet és raktáron lévő termék – Időben történő kézbesítést biztosít ipari projektekhez.

Rendelje meg az ERNiCrMo-4 (C-276) sövért drágaként!

Keresi a minőségi vízszintvonalas drótkötést nemzetközi árakkal? Lépjen kapcsolatba velünk nagy mennyiségű rendelésekért, személyre szabott megoldásokért és gyors világszertei szállítással.

| Tétel | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ErNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2,5-3,5 | 4 | 0.5-1.0 | 1 |

| Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | pihenés | pihenés | 0.25 |

| Ni | ≥58 | pihenés | pihenés | pihenés | ≥67 | 62-69 | 30-32 | ≥93 |

| A | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

| AL | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

| Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2,0-3,0 | N/A | N/A | N/A |

| Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

| V. | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

| W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

| Pihenés | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 | ≤ 0,50 |

| Nikkel és nikkel-ligavas vonalkapcsoló drót | |

| Termék modell (AWS) | Alkalmazás |

| ERNiCr-3 | A 600, 601 és 800 ligavak önmaguk közötti illesztéséhez, valamint a rostmentes és szén-tartalmú acélok különböző fémek közötti illesztéséhez ERNiCrFe-7; Az Inconel ligavak illesztéséhez az ASTM B163, 166, 167 és 168 keretében |

| ERNiCrFe-6 | Acél és Inconel illesztéséhez, acél és rostmentes acél illesztéséhez, valamint nikkelalapú ligavak illesztéséhez |

| ERNiCrCoMo-1 | Különböző típusú összefonás a nikkel-krom-kobalt-molybdenum hõmörsegek és különféle szuperhõmörsegek fonása során |

| ERNiCrMo-3 | Nikkelhõmörseg, szénvasa, rostmentes acél és alacsony legyszámú acél fonására használják, főként az 625, 601, 802 hõmörseg fonására és a 9%-os nikkelhõmörseg fonására |

| ERNi-CI | Ipari tiszta nikkel fonásra műanyagosságú és fekete dúszfémetre |

| ERCuNi | 70/30, 80/20, 90/10 réz-nikkel hõmörsegek fonására |

| ErNiCu-7 | Nikkel-réz hõmörsegek fonására, mint a B127, 163, 164 és 165 stb. |

| ERNi-1 | Tiszta nikkel gúlyaforgalmi és -varázslati anyagok fonására, például az ASTM B160, 161, 162, 163 tartománybeli hõmörsegekhez |

| ERNiFeMn-CI | Gömbulesztetett dúszfémet, rugalmas dúszfémet, műanyagosságú dúszfémet és fekete dúszfémet fonására magától vagy rostmentes acél, szénvasa, alacsony legyszámú acél és különféle nikkelhõmörsegekhez |

| ERNiCrMo-4 | A nikel-krom-molybdenum-ligavány önmagára való vagy a nikel-krom-molybdenum-ligavány és a vas, valamint a legtöbb más nikelalapú ligavány összefűzésére használatos |

| ERNiCrMo-11 | Használatos a nikel-krom-molybdenum-ligavány saját maga összefűzésére, vagy a nikel-krom-molybdenum-ligavány és a vas, valamint a legtöbb más nikelalapú ligavány összefűzésére, továbbá felületi összefűzésre is alkalmas a nikel-krom-molybdenum-ligavány és a vasös csavarvonalakhoz |

| ERNiCrMo-13 | Alacsony szén tartalmú nikel-krom-molybdenum-ligaványok összefűzésére |