Ni201 Elektrodni Šip Nickel 5mm-20mm | Za Svarivanje i Kemijsku Industrij

Ponudujemo cijene izravno s tvornice i posebne popuste za porudžbine u velikom obimu. Bez obzira jesu li vam potrebne male ili velike količine, naša proizvoda brzo šaljemo kako bismo osigurali pouzdan snabdevanje za industrijske projekte širom svijeta.

- Pregled

- Specifikacija

- Prijave

- ČESTO POSTAVLJANA PITANJA

- Preporučeni proizvodi

Uvod u Ni201 Elektrodni Šip od Nikla

Ni201 Elektrodni Šip od Nikla je svarivački materijal visoke čistoće namijenjen industrijskom svarivanju, kemijskoj obradi i primjenama otpornim na koroziju. S sadržajem nikla od ≥99,6%, Ni201 pruža izuzetnu toplinsku i električnu vodljivost, odličnu otpornost na koroziju i izvrsnu mehaničku jačinu.

Naš Ni201 Elektrodni Šip od Nikla (promjerom 5mm-20mm) dostupan je za TIG, MIG i ark svarivanje, čime postaje idealan izbor za izradu, popravke i visoko temperaturne okoline. Ponudili smo cijene direktno s tvornice i opcije masovnog snabdijevanja širom svijeta kako bismo zadovoljili raznovrsne industrijske potrebe.

Ključne Značajke Ni201 Elektrodnog Šipa od Nikla

Visoka Čistoća Nikla (≥99,6%) – Osigurava odličnu otpornost na koroziju i stabilnost.

Odlično Svarivost – Prikladno za TIG, MIG i druge metode fuzijskog svarivanja.

Odlična otpornost na toplinu – Izvrsno funkcionira u industrijskim okruženjima visokih temperature.

Izvrstan provedba struje – Idealan za električne i elektronske komponente.

Dobri mehanički osobine – Ponudjuje visoku izdržljivost na povlačenje i fleksibilnost.

Ponuda iz fabrike – Dostupne prilagođene veličine i podrška OEM.

Primjene Ni201 niklova elektrodnog šipka

1. Industrijsko spajanje i proizvodnja

Koristi se u primjenama TIG, MIG i lukovitog spajanja.

Idealan za spojivanje nikelovih legura, nerustinglog čelika i različitih metala.

Osigurava jak, korozijono otporni spoj za stroge uvjete.

2. Oprema za obradu kemijskih tvari

Nedostatak za čvrstošću rezervoara, cijevi i toplinskog razmjenača otpornog na koroziju.

Koristi se u kemijskim zavodima, rafinerijama i objektima za proizvodnju kiseline.

Izdržava kiseline i bazene rješenja bez deteroracije.

3. Aerospacijalne i pomorske primjene

Primjenjuje se u komponentama leteljskih motora i pomorskim konstrukcijama.

Ponudi otpornost na oksidaciju pri visokim temperaturama.

Koristi se u proizvodnji opreme za mora i odbranu na otvorenom moru.

4. Električna i elektronska industrija

Služi kao materijal elektroda u električnim kontaktima i komponentama.

Primjenjuje se u šemama, proizvodnji baterija i prijenosu moći.

Osigurava nisku rezistivnost i visoku učinkovitost.

| Specifikacija | Detalji |

|---|---|

| Materijal | Ni201 Čisti nikl (≥99.6%) |

| Dijametar | 5mm – 20mm (Prilagođivo) |

| Duljina | 500mm – 3000mm (Prilagođivo) |

| Standardna uključenost | ASTM B160, ASME SB-160, GB/T 2072-2007 |

| Talište | 1435°C (2615°F) |

| Soprtnost na povlačenje | ≥380 MPa |

| Električna Otpornost | ≤0.099 Ω·mm²/m |

Zašto izabrati naše Ni201 niklin elektrodni šipke?

✔ Visoka čistoća za odlične performanse u svarivanju i industrijskoj uporabi

✔ Prilagođene veličine i raspoloživa velikom proizvodnji

✔ Konkurentna cijena i pouzdan snabdevanje u velikim količinama

✔ Brza globalna dostava i podrška OEM

ČPP:

Koliko dugo traje isporuka?

Ovisi o količini narudžbine, za male narudžbine 10-30 dana. Za velike narudžbine potrebno je 60 dana.

Prihvatate li OEM/ODM proizvodnju?

Da! Prihvatamo OEM/ODM proizvodnju. Možete nam poslati vaše uzorke ili crteže.

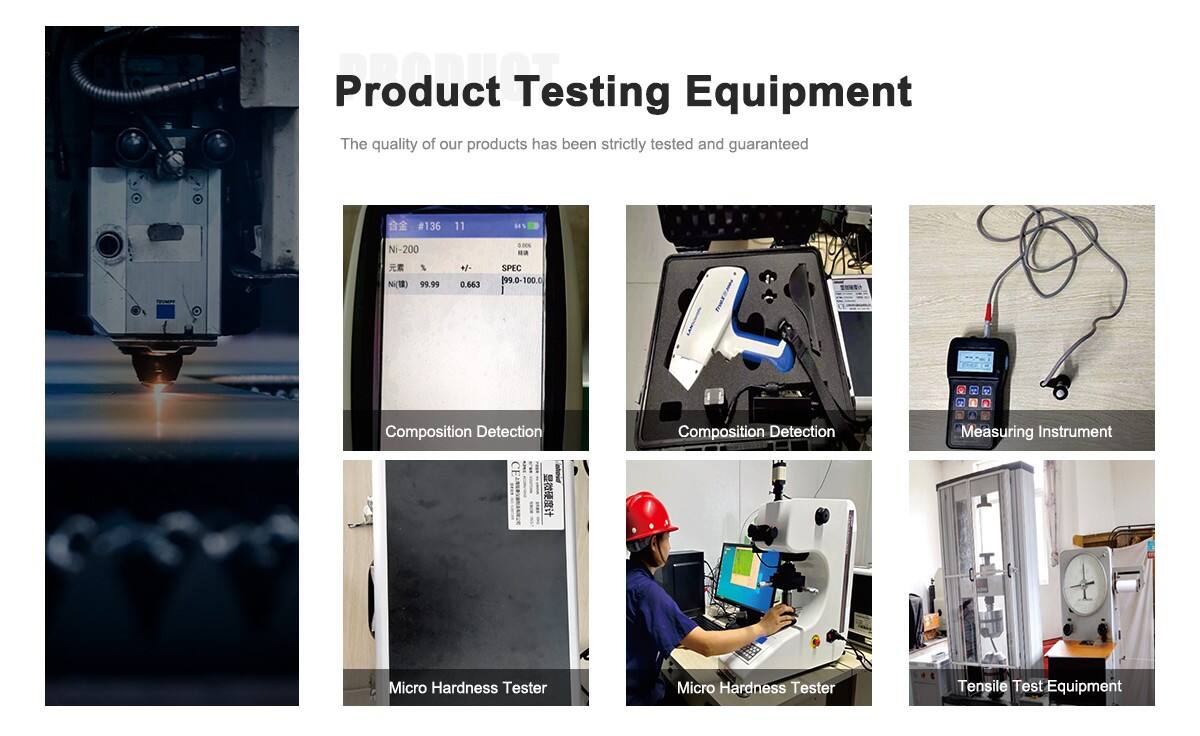

Kako kontrolirate kvalitet vaših proizvoda? Da li kemikalne svojstva proizvoda ispunjavaju standard kvaliteta?

Sa profesionalnim timom za kvalitet, naprednom planiranjem kvaliteta proizvoda, strogom implementacijom i neprestanim unapređivanjem, izdat ćemo certifikat o inspekciji kvaliteta proizvoda, uključujući izvještaj o kemikalnoj analizi.

Može li vaša tvrtka pružiti detaljne tehničke podatke i crteže?

Jeste, možete. Recite nam koje proizvode i primjene vam trebate, a mi ćemo vam poslati detaljne tehničke podatke i crteže za vašu procjenu i potvrdu.

Kako obradujete usluge prije i nakon prodaje?

Imamo profesionalni poslovni tim koji će raditi jedan na jedan da bi štitovali vaše potrebe proizvoda, a ako imate bilo kakve pitanje, on će vam ih odgovoriti!

Možem li posjetiti vašu tvornicu prije nego što podnesem narudžbu?

Da, dobrodošli ste u našu tvornicu. Sreti smo imamo priliku upoznati se.

Gdje je vaša proizvodna baza?

Proizvodimo naše proizvode u Jiangsu, Kini i šaljemo ih iz Kine u vašu zemlju što prije, što uglavnom ovisi o zahtjevima za proizvodom i količinom.

Možete li poslati uzorke?

Da, možemo.