High-Temperature 0Cr25Al5 Wire & Strip – Superior Heating Element Material

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

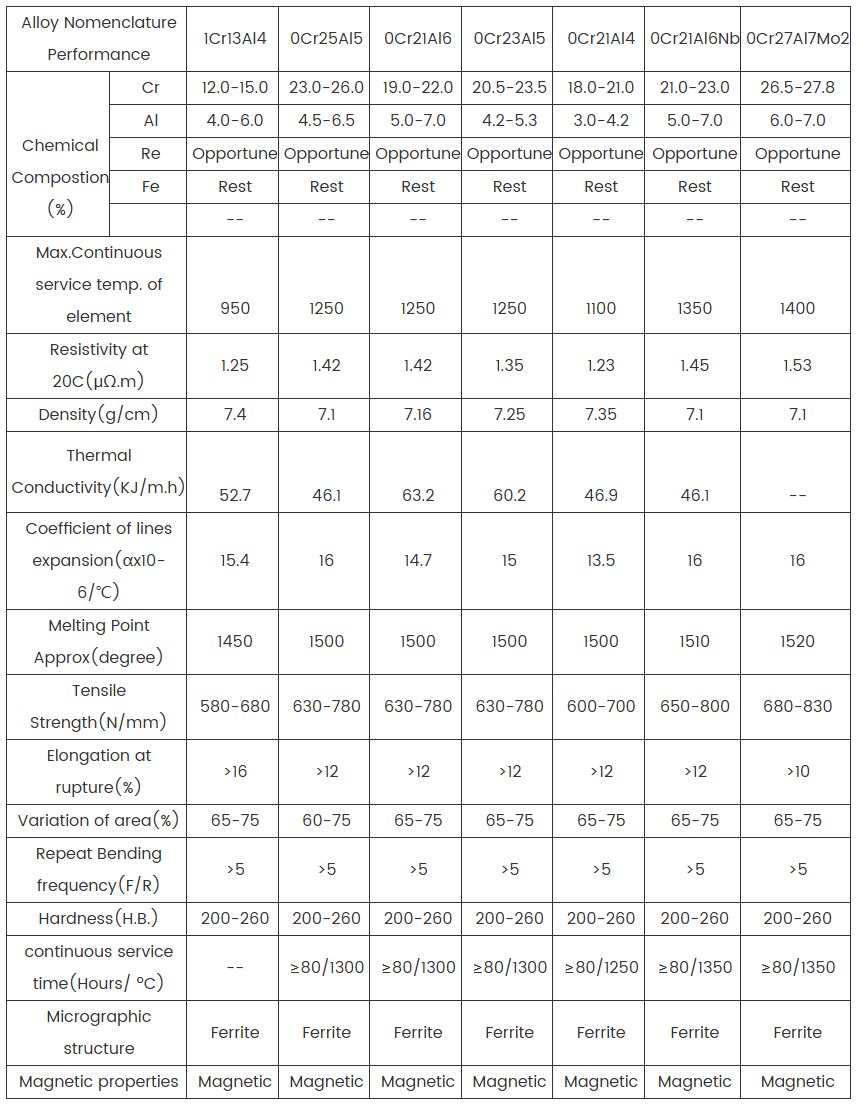

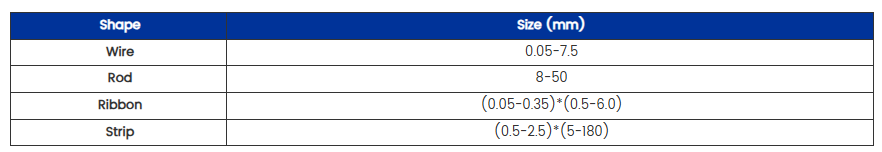

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

-

High-Temperature Resistance: Withstanding temperatures up to 1300°C, making it ideal for prolonged exposure to extreme heat.

-

Excellent Oxidation Resistance: Forms a stable aluminum oxide (Al2O3) protective layer, preventing surface degradation.

-

Superior Electrical Resistance: Ensures efficient energy conversion in heating applications.

-

Long Service Life: Durable and resistant to deformation and cracking under high temperatures.

-

Good Mechanical Strength: Maintains structural integrity even under thermal cycling conditions.

-

Efficiency: High electrical resistance ensures optimal power consumption.

-

Durability: Long lifespan reduces the frequency of replacements, saving operational costs.

-

Versatility: Suitable for a wide range of industrial and commercial heating applications.

-

Customizability: Available in various diameters, thicknesses, and formats (wire, strip, coil) to meet specific application requirements.

-

Different thicknesses and diameters to match varying power and heating requirements.

-

Surface treatments for enhanced oxidation resistance.

-

Coil and spool options for ease of installation and handling.

-

Technical consultation to ensure the best material choice for specific applications.

0Cr25Al5 is a high-performance iron-chromium-aluminum (FeCrAl) alloy known for its excellent high-temperature resistance, superior oxidation resistance, and long service life. This alloy contains approximately 25% chromium and 5% aluminum, which significantly enhances its stability and durability in extreme thermal environments. Due to these outstanding properties, 0Cr25Al5 wire and strip have become essential materials for various industrial heating applications.

Key Properties of 0Cr25Al5 Wire & Strip

Applications of 0Cr25Al5 Wire & Strip

Given its remarkable properties, 0Cr25Al5 wire and strip are widely used in various high-temperature and industrial applications, including:

1. Electric Heating Elements

0Cr25Al5 is commonly used in manufacturing resistance heating wires and strips for electric furnaces, industrial kilns, and household heating appliances. The material's high resistance and stability ensure consistent heating performance and efficiency.

2. Metallurgical and Glass Industry

In high-temperature processing industries such as metallurgy and glass manufacturing, 0Cr25Al5 heating elements are used in continuous furnaces, annealing ovens, and other thermal processing equipment. Its high-temperature stability ensures precise control over the production process.

3. Automotive and Aerospace Applications

The alloy is used in specialized automotive and aerospace heating applications, including exhaust systems, catalytic converter heaters, and aircraft engine components that require prolonged exposure to high temperatures.

4. Chemical and Petrochemical Industry

0Cr25Al5 is utilized in chemical and petrochemical processing plants for heating elements in reactors, distillation columns, and fluidized bed combustion systems. Its corrosion resistance against aggressive gases and chemicals enhances operational longevity.

5. Power Generation

In power plants, this alloy is used in boiler heating elements and high-temperature gas heaters. Its oxidation resistance and durability contribute to energy efficiency and reduced maintenance costs.

Meeting User Needs

Why Choose 0Cr25Al5 Wire & Strip?

Customers seeking a reliable and long-lasting heating element material prefer 0Cr25Al5 for its exceptional performance in extreme conditions. Key factors driving the demand for this material include:

Customization and Technical Support

To cater to diverse industrial needs, manufacturers offer customized specifications of 0Cr25Al5 wire and strip, including:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.