High-Performance Invar36 Wires for Accurate Thermal Expansion Control in Electronics

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

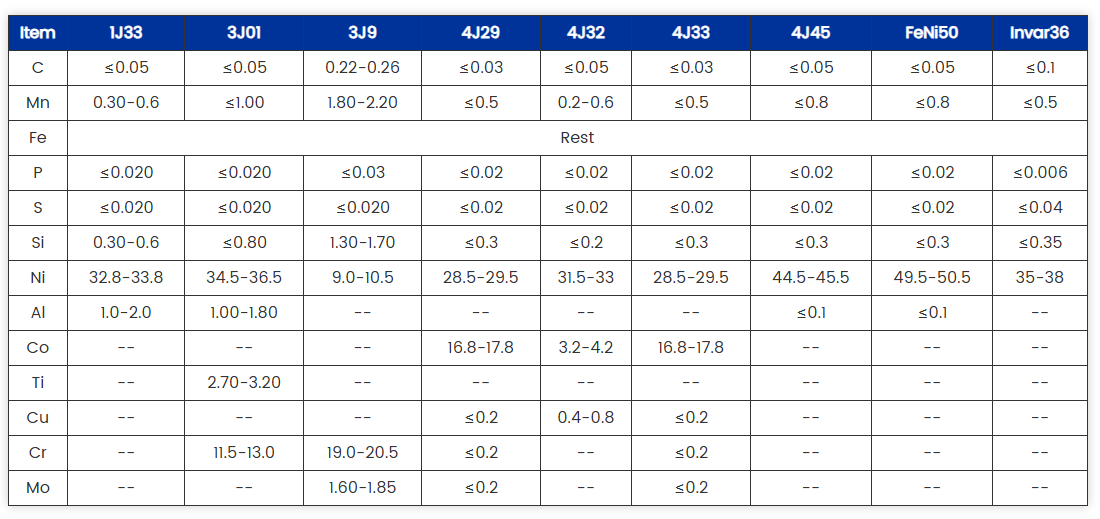

- Specification

- About Us

- FAQs

- Recommended Products

-

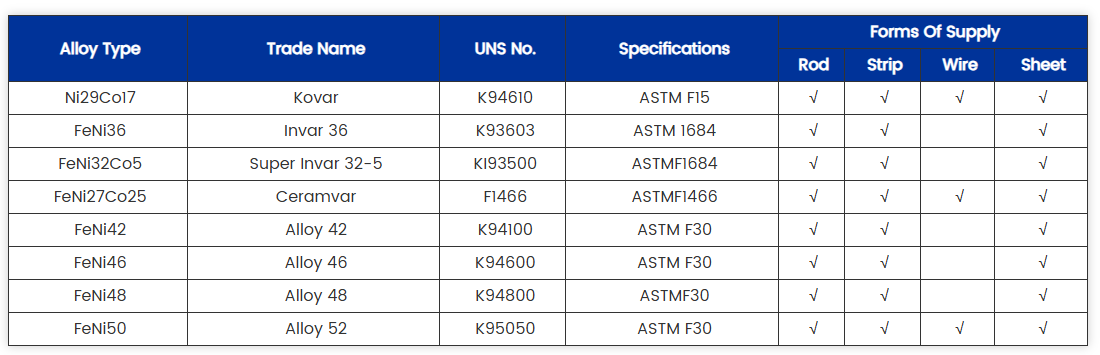

Electronic Devices and Components Invar36 wires are commonly used in the manufacturing of electronic components where thermal stability is crucial. In devices like sensors, connectors, transistors, and circuit boards, even small changes in temperature can lead to performance issues or failure. The low CTE of Invar36 helps minimize the expansion and contraction of components, ensuring that the electronic devices operate consistently, even in environments where temperatures fluctuate. This makes Invar36 an ideal choice for high-performance electronics such as smartphones, computers, and wearables.

-

Semiconductor Industry The semiconductor industry relies heavily on materials that can maintain dimensional stability during both manufacturing and operational processes. Invar36 wires are used in semiconductor manufacturing equipment to ensure that sensitive components, such as chips and microprocessors, remain unaffected by temperature variations. The alloy’s low thermal expansion prevents misalignment or distortion of components during the fabrication and testing stages, ensuring that products meet high-precision standards.

-

Precision Measurement Equipment Invar36 wires are widely employed in precision measurement instruments due to their ability to remain dimensionally stable in a range of temperatures. Instruments such as thermometers, measuring devices, and calibration tools require materials with stable properties over temperature cycles. Invar36 ensures that the accuracy of these instruments is maintained, providing reliable measurements for scientific research, manufacturing, and quality control processes.

-

Optical Systems and Lasers In optical systems, such as lasers, microscopes, and telescopes, the accuracy of the system can be heavily influenced by changes in temperature. Invar36 wires are used in the mounting and alignment systems of optical equipment to prevent distortion. The wires help maintain the alignment of sensitive optical components, ensuring precise focus and image quality. This makes them vital in industries such as medical imaging, astronomy, and laser technology.

-

Aerospace and Satellite Systems Aerospace and satellite applications often require materials that can withstand extreme temperature variations while maintaining dimensional integrity. Invar36 wires are employed in satellite systems, spacecraft, and aerospace sensors, where temperature extremes are common during launch, re-entry, and space travel. These wires are used in structural elements, thermal shields, and sensor mounts to ensure that the performance of these systems is not compromised by thermal expansion or contraction, allowing them to function reliably in space environments.

-

Medical Devices and Imaging Systems Medical devices, such as MRI machines, CT scanners, and surgical instruments, require materials that can maintain their accuracy over time despite exposure to varying temperatures. Invar36 wires are used in the construction of critical components in these devices, where dimensional stability and thermal control are essential for ensuring precise results and patient safety. The alloy’s low CTE prevents the distortion of critical parts, which could otherwise lead to inaccurate readings or equipment malfunction.

-

Thermal Stability Users of Invar36 wires demand high thermal stability in order to ensure that their electronic and measurement systems perform accurately across a wide range of temperatures. For industries such as electronics, telecommunications, and aerospace, temperature-induced dimensional changes can cause serious malfunctions or degrade the performance of the system. Invar36’s low coefficient of thermal expansion ensures that components remain dimensionally stable, regardless of temperature fluctuations, offering users the reliability and accuracy they require.

-

Precision and Accuracy In industries such as semiconductors and optics, precision is non-negotiable. Users need materials that help maintain tight tolerances in their manufacturing and measurement processes. Invar36 wires, with their ability to remain dimensionally stable under varying temperatures, ensure that precision instruments continue to deliver accurate results even in challenging environmental conditions. These materials are crucial for customers who depend on high-performance equipment for critical applications, ensuring consistent performance across various industries.

-

Durability and Longevity Customers who use Invar36 wires require a material that not only offers dimensional stability but also provides long-term durability. Whether used in satellite systems, medical devices, or industrial equipment, these wires must withstand years of use without losing their mechanical properties. Invar36’s resistance to corrosion and thermal degradation ensures that it maintains its structural integrity over time, providing long-lasting performance in high-stakes applications.

-

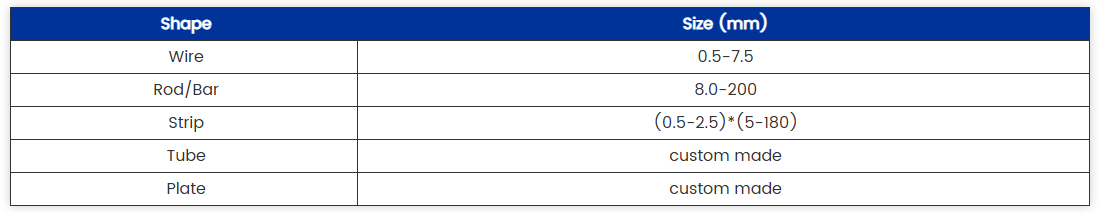

Customization and Versatility Users often require customized solutions that can meet specific design and application needs. Invar36 wires are available in various diameters and lengths, making them suitable for a wide range of applications, from high-precision electronics to large-scale aerospace systems. Customers appreciate the versatility of Invar36, which can be adapted to suit a variety of high-performance and sensitive applications, ensuring that their unique requirements are met.

-

Reliability in Extreme Environments Many industries, particularly aerospace, medical, and telecommunications, operate in extreme environments where temperature changes, humidity, and other conditions could affect performance. Invar36 wires are designed to perform reliably in such environments, providing users with a material that maintains its properties under challenging conditions. Whether exposed to the vacuum of space or the fluctuating temperatures of electronics, Invar36 ensures that equipment remains functional and precise.

Invar36 is an iron-nickel alloy with a composition that includes 36% nickel and the remaining iron. It is known for its extremely low coefficient of thermal expansion (CTE), making it one of the best materials for applications requiring precise thermal expansion control. Due to its remarkable stability under varying temperature conditions, Invar36 wires are extensively used in fields where dimensional accuracy is critical, such as electronics, aerospace, and high-precision instrumentation. These wires maintain their shape and dimensions even when exposed to temperature fluctuations, making them indispensable for sensitive electronic devices and systems.

Applications of Invar36 Wires

User Demands and Requirements

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.