High-Performance Inconel 718 Spring Wire for Automotive and Nuclear Industries

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

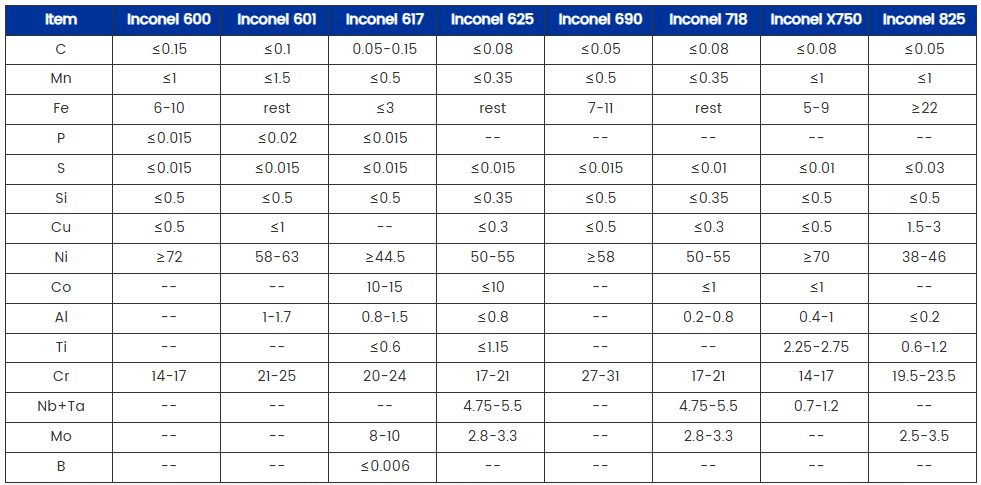

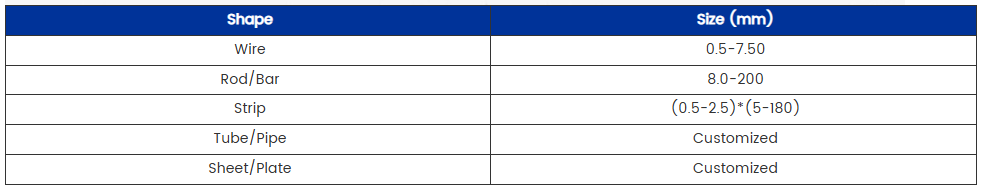

- Specification

- Applications

- FAQs

- Recommended Products

Inconel 718 nickel-based superalloy spring wire has become the material of choice for critical components in automotive and nuclear industries due to its exceptional mechanical properties and environmental adaptability.

Key Performance Features:

Extreme Environment Stability

Maintains excellent mechanical properties across a wide temperature range (-253°C to 704°C)

Meets stringent radiation resistance requirements for nuclear reactors

Oxidation resistance 3-5 times better than conventional stainless steels

Mechanical Property Advantages

Tensile strength reaches 1240 MPa (180 ksi)

Fatigue life 8-10 times longer than standard spring steels

Creep rupture time exceeds 10,000 hours at 700°C

Special Environment Tolerance

Complete resistance to stress corrosion cracking (SCC)

Maintains stability across pH range of 2-12

Outstanding neutron radiation damage resistance

Innovative Industry Applications

Cutting-Edge Automotive Applications

New Energy Powertrain Systems:

Hydrogen fuel cell bipolar plate contact springs (contact pressure >200N/mm²)

800V fast-charging interface elastic components

Smart suspension system actuator core springs

Traditional Powertrain Upgrades:

Variable Geometry Turbocharger (VGT) adjustment mechanisms

48V mild hybrid system electromagnetic clutches

EGR valve springs meeting Euro 7 emission standards

Critical Nuclear Applications

Generation IV Reactors:

Sodium-cooled fast reactor control rod drive mechanisms

Molten salt reactor main pump mechanical seal springs

High-temperature gas-cooled reactor fuel ball circulation systems

Nuclear Fuel Cycle:

High-level waste liquid valves in reprocessing plants

MOX fuel manufacturing equipment springs

Dry storage container sealing systems

Market Development Trends

Surging Automotive Industry Demand

Global NEV spring market projected to reach $3.2B by 2025

Turbocharger penetration exceeding 50% creating new demand

Smart chassis systems driving 15% annual growth in precision springs

Nuclear Renaissance Opportunities

58 nuclear power units under construction worldwide (IAEA data)

Accelerating commercialization of Small Modular Reactors (SMRs)

New construction/renovation wave for nuclear fuel cycle facilities

Technology Convergence Innovations

Digital Manufacturing

Digital twin-based spring design optimization

Online quality monitoring systems with ±1μm accuracy

AI-driven process parameter optimization

Composite Processing Technologies

Ultra-precision wire drawing (surface roughness Ra<0.1μm)

Laser-assisted forming with ±5μm accuracy

Plasma surface modification technology

Sustainable Development

Scrap recovery rates exceeding 95%

Low-carbon production processes reducing emissions by 30%

Establishment of product Life Cycle Assessment (LCA) systems

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.