High-Accuracy K-Type Thermocouple Extension Wire (NiCr-NiAl) for Industrial Temperature Monitoring

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

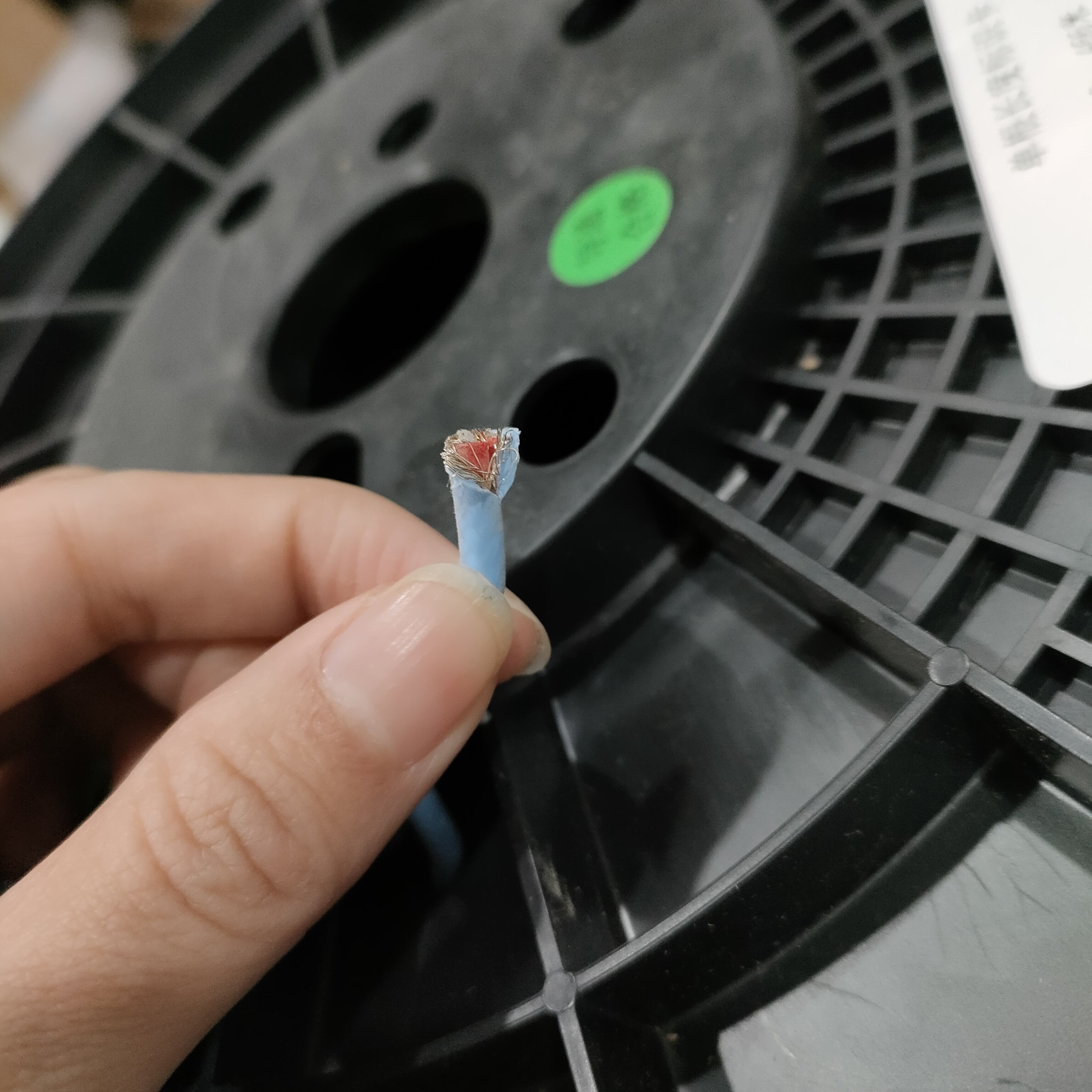

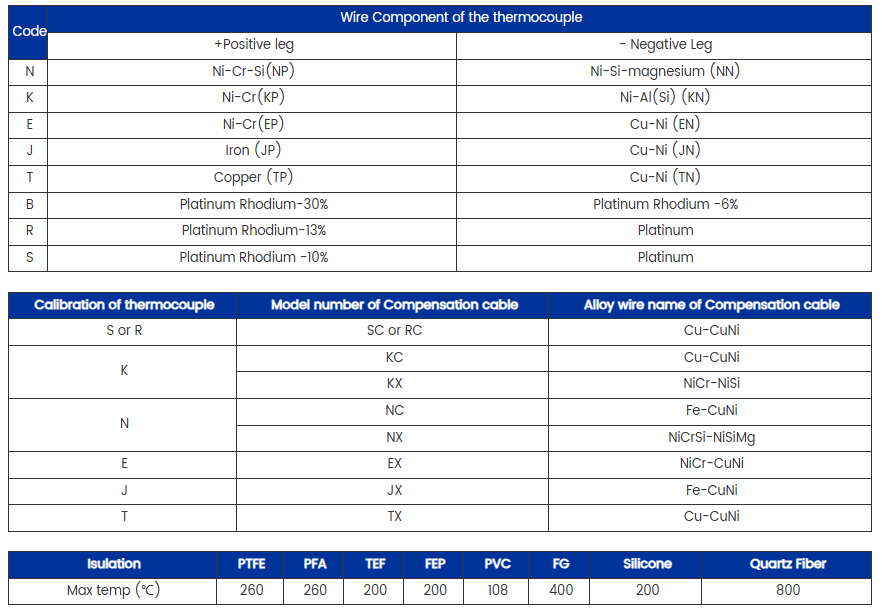

The K-Type thermocouple is one of the most widely used temperature sensors in industrial applications, known for its versatility, wide temperature range, and reliability. The K-Type thermocouple extension wire, made of Nickel-Chromium (NiCr) and Nickel-Aluminum (NiAl), plays a crucial role in ensuring high-accuracy temperature measurement. This extension wire is typically used to extend the reach of the thermocouple while maintaining the accuracy of the temperature readings. With a wide array of applications, the K-Type extension wire is an essential component for industrial temperature monitoring, process control, and other high-performance measurement systems.

In this article, we will explore the materials, applications, and user requirements for high-accuracy K-Type thermocouple extension wire, emphasizing its significance in industrial temperature monitoring.

Material Composition and Characteristics

K-Type thermocouple extension wire consists of Nickel-Chromium (NiCr) and Nickel-Aluminum (NiAl), which are used for their excellent thermoelectric properties and durability in harsh environments.

NiCr: The positive leg of the K-Type thermocouple extension wire is made from Nickel-Chromium alloy, which provides excellent resistance to oxidation, high-temperature stability, and good corrosion resistance.

NiAl: The negative leg is made from Nickel-Aluminum alloy, offering similar stability and performance, ensuring a balanced thermoelectric response.

Key Features

Wide Temperature Range: K-Type extension wire can operate efficiently in temperatures ranging from -200°C to 1,370°C (-328°F to 2,500°F), making it suitable for diverse industrial applications.

High Accuracy: The wire ensures high-accuracy temperature measurement, which is critical in process control and monitoring systems, with an error range of approximately ±2°C.

Durability: Designed for demanding industrial environments, the wire is resistant to physical wear, corrosion, and chemical exposure, ensuring long-lasting performance.

Flexibility: The wire is flexible, making it easy to install and integrate into existing systems without compromising its accuracy and durability.

Minimal Drift: K-Type extension wire provides stable readings with minimal drift over time, which is crucial for processes requiring consistent temperature measurement.

Applications of K-Type Thermocouple Extension Wire

Due to its durability, accuracy, and wide temperature range, K-Type thermocouple extension wire is used in various industries that require precise and reliable temperature monitoring.

1. Industrial Temperature Monitoring

Manufacturing and Processing Plants: K-Type extension wires are commonly used to monitor the temperature of industrial furnaces, kilns, reactors, and other processing equipment. This ensures that temperatures are maintained within specified limits, improving product quality and preventing equipment damage.

Chemical and Petrochemical Industries: In chemical production and petrochemical refining, precise temperature measurement is essential for ensuring the safe and efficient operation of reactors and distillation columns. K-Type thermocouple extension wire provides the necessary reliability and accuracy for temperature control in these high-demand environments.

Energy Production and Power Plants: In power generation facilities, K-Type extension wires are used to measure the temperature of steam, gases, and cooling systems. Accurate temperature control is vital for maximizing efficiency and preventing overheating or damage to turbines and reactors.

2. Food and Beverage Industry

K-Type thermocouple extension wires are essential in the food and beverage industry, where precise temperature monitoring ensures product quality and safety. They are used to control the temperature of ovens, pasteurization tanks, and cold storage units, guaranteeing the proper conditions for food processing, preservation, and packaging.

3. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, K-Type thermocouple extension wire helps maintain optimal temperatures in residential, commercial, and industrial buildings. This application is critical for energy efficiency and comfort, and the wire's durability ensures it performs reliably over time.

4. Automotive Industry

In the automotive sector, K-Type thermocouple extension wires are used in engine testing, exhaust systems, and other high-temperature areas to monitor and control temperature. High-accuracy temperature measurement is critical for performance testing, engine calibration, and ensuring vehicle safety.

5. Environmental Testing

K-Type extension wires are used in environmental chambers and laboratories for temperature simulation and testing. These chambers are essential for testing products under different temperature conditions to simulate various environmental stresses, such as extreme cold or heat.

Meeting the Needs of Industrial Users

Industrial users of K-Type thermocouple extension wire require specific characteristics to ensure the success of their operations. Here are the main needs and how K-Type extension wire meets them:

1. Accuracy and Reliability

One of the primary requirements for industrial users is high-accuracy temperature measurement. K-Type extension wire ensures precise temperature readings, which is essential for process control and quality assurance. The wire’s reliability ensures consistent performance even in extreme environments.

2. Durability in Harsh Environments

Industrial environments often involve extreme conditions, such as high temperatures, corrosive chemicals, and mechanical stress. K-Type thermocouple extension wire is designed to withstand these harsh conditions, ensuring long-term performance and minimal maintenance.

3. Ease of Integration

For industrial users, the ability to easily install and integrate the K-Type extension wire into existing temperature monitoring systems is critical. The wire’s flexibility and compatibility with a wide range of thermocouples make it ideal for various applications across industries.

4. Cost Efficiency

K-Type thermocouple extension wire is a cost-effective solution for industrial temperature monitoring. Despite offering high accuracy and durability, it is affordable, making it a preferred choice for industries that need to balance performance and cost-effectiveness.

5. Customization Options

Industrial users often have specific requirements in terms of wire length, gauge, and insulation. K-Type thermocouple extension wire can be customized to meet these needs, offering flexibility in how it is used across different applications.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.