Hastelloy B-3 तार – प्रसिद्ध निर्माण और प्रतिस्पर्धी कीमत

हम फैक्ट्री डायरेक्ट कीमतों और बड़े पैमाने पर ऑर्डर के लिए विशेष छूट प्रदान करते हैं। चाहे आपको छोटी या बड़ी मात्रा में उत्पाद चाहिए, हमारे उत्पाद जल्दी भेजे जाते हैं ताकि विश्वभर के औद्योगिक परियोजनाओं के लिए विश्वसनीय आपूर्ति सुनिश्चित हो।

- सारांश

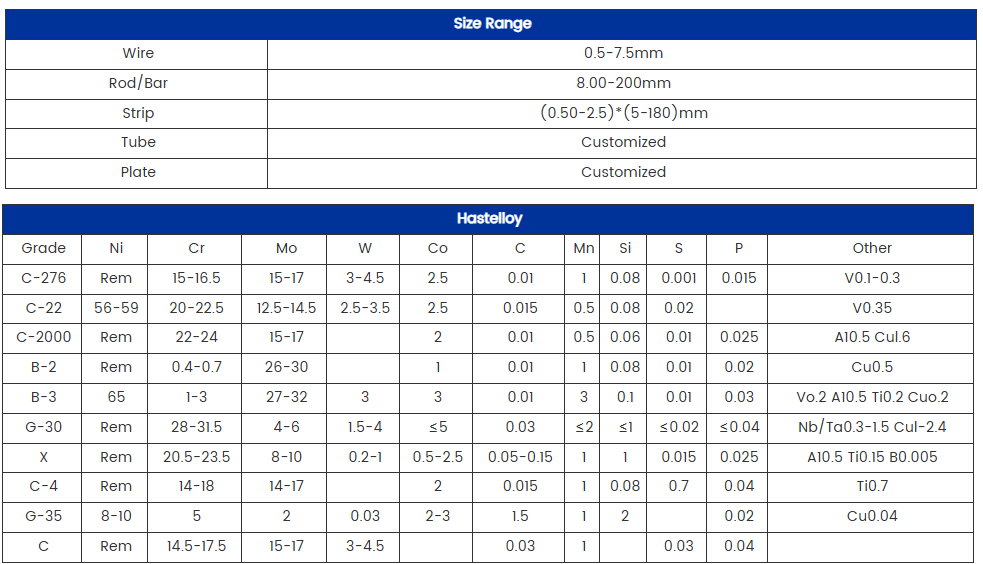

- विनिर्देश

- अनुप्रयोग

- पूछे जाने वाले प्रश्न

- अनुशंसित उत्पाद

-

अत्यधिक कारोबार प्रतिरोध: हाइड्रोक्लोरिक, सल्फ्यूरिक और फॉस्फोरिक अम्ल जैसे कमजोर परिवेश में अपना काम बढ़िया तरीके से करता है।

-

उच्च थर्मल स्टेबिलिटी: ऊंचे तापमान पर अपने यांत्रिक और रासायनिक गुणों को बनाए रखता है।

-

विशिष्ट यांत्रिक ताकत: सहनशीलता, लचीलापन और तनाव कारोबार फटने से प्रतिरोध को सुनिश्चित करता है।

-

शुद्ध निर्माण क्षमता: उच्च ताकत और कारोबार प्रतिरोध बनाए रखते हुए सूक्ष्म तारों में खींचा जा सकता है।

-

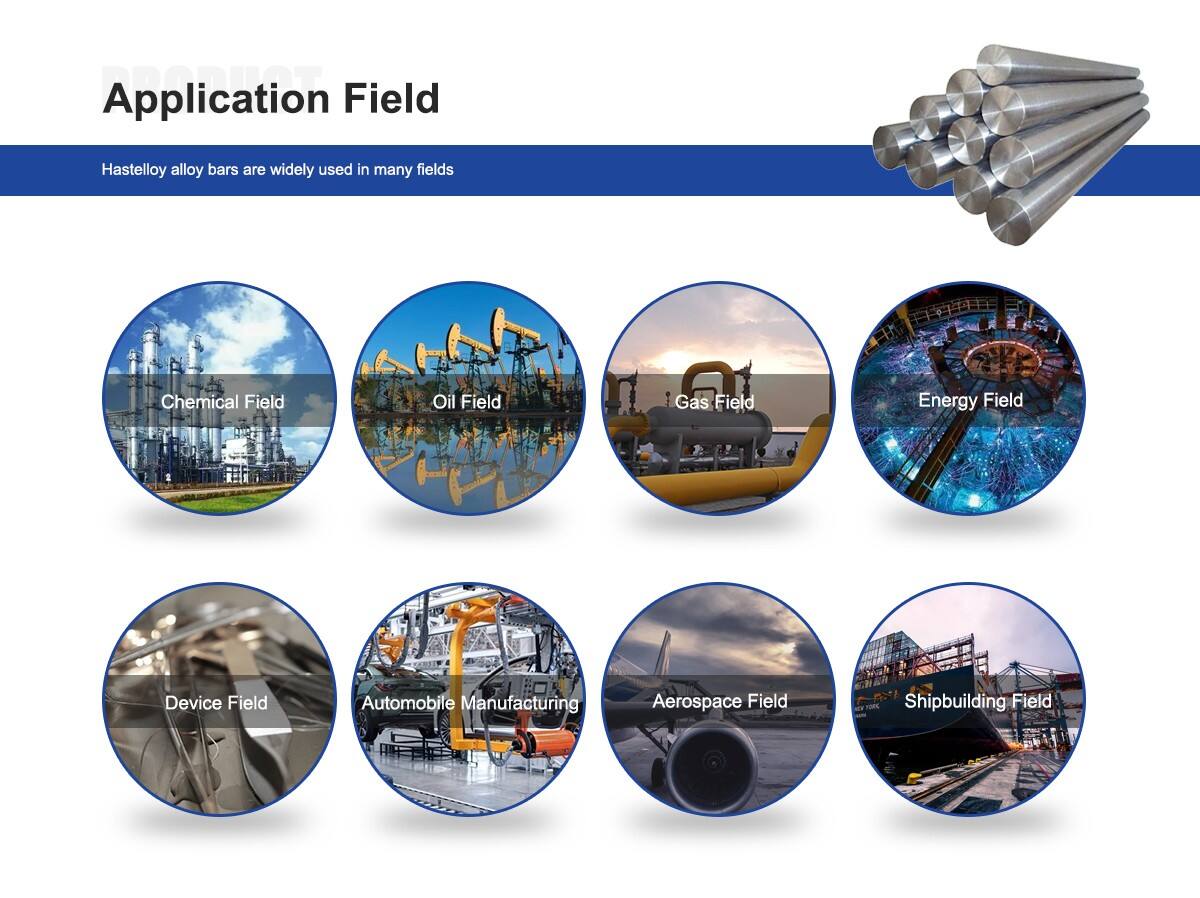

रासायनिक प्रसंस्करण उद्योग: तार जाल, फ़िल्टरेशन प्रणाली और रासायनिक-प्रतिरोधी फ़ास्नर्स में उपयोग किया जाता है।

-

इलेक्ट्रॉनिक्स और इलेक्ट्रिकल घटक: विशेष विद्युत अनुप्रयोगों के लिए उपयुक्त है जिनमें कारोबार-प्रतिरोधी चालक की आवश्यकता होती है।

-

विमान और रक्षा: उच्च-प्रदर्शन सेंसर, घटकों और संरचनात्मक सुदृढ़ीकरण में उपयोग किया जाता है।

-

चिकित्सा और फार्मास्यूटिकल उद्योग: स्टेरिल उपकरण, शल्य उपकरण और प्रयोगशाला अनुप्रयोगों में लगाया जाता है।

-

समुद्री और बेहिसाब इंजीनियरिंग: समुद्री पानी के प्रतिरोधी अनुप्रयोगों के लिए आदर्श, जिसमें स्प्रिंग्स और केबल्स शामिल हैं।

-

UNS Number: N10675

-

एसटीएम मानक: ASTM B335 (तार और छड़ें)

-

EN/DIN Equivalent: 2.4600

-

पिघलाव और मिश्रण: शुद्धता बनाए रखने के लिए वैक्यूम इंडक्शन पिघलाव (VIM) या इलेक्ट्रिक आर्क फर्नेस (EAF) का उपयोग करके बनाया जाता है।

-

गर्म और ठंडे खींचने: सटीक आयामों को यकीनन करता है और यांत्रिक गुणों को बढ़ाता है।

-

अन्नेरिंग और गर्मी का उपचार: लचीलापन, बर्फीली प्रतिरोधकता और संरचनात्मक स्थिरता में सुधार करता है।

-

सतह परिष्करण: ब्राइट अन्नेरिंग, ऑक्सीडाइज्ड या कोटेड समापन शामिल हैं, जो प्रदर्शन में बढ़ोतरी करते हैं।

-

गुणवत्ता नियंत्रण और परीक्षण: यांत्रिक गुण अनुमान, संक्षारण प्रतिरोध परीक्षण और आयाम जाँचें शामिल हैं।

-

विविध तार व्यास: विशिष्ट अनुप्रयोगों को समेटने के लिए विभिन्न मोटाइयों में उपलब्ध है।

-

सरफेस फिनिश विकल्प: बढ़िया सहनशीलता के लिए चमकदार, काले, या कोटेड फिनिश।

-

प्रसिद्धता पूर्वक कटिंग और स्पूलिंग सेवाएं: सटीक माप और उपयोग की सुविधा।

-

ओईएम और बल्क ऑर्डर कस्टमाइज़ेशन: बड़े पैमाने पर उद्योगी परियोजनाओं के लिए संशोधित उत्पादन।

हेस्टेलॉय B-3 एक निकेल-मोलिब्डेनम एल्युमिनियम है जो अत्यधिक रिड्यूसिंग परिवेशों, विशेष रूप से हाइड्रोक्लोरिक एसिड और अन्य खराब रासायनिक पदार्थों के खिलाफ अच्छी प्रतिरोधक क्षमता के लिए डिज़ाइन किया गया है। एक तार सामग्री के रूप में, यह उत्कृष्ट रासायनिक प्रतिरोधकता, यांत्रिक ताकत और ऊष्मीय स्थिरता प्रदान करता है, जिससे यह विभिन्न उद्योगों में सटीक निर्माण अनुप्रयोगों के लिए आदर्श विकल्प बन जाता है।

सामग्री संघटन और गुण

हेस्टेलॉय B-3 तार मुख्य रूप से निकेल और मोलिब्डेनम से बना होता है, जो रासायनिक हमले के खिलाफ सुधारित स्थिरता प्रदान करता है। मुख्य विशेषताएं इन्हें शामिल करती हैं:

हैस्टेलॉय B-3 तार के अनुप्रयोग

अपने उत्कृष्ट गुणों के कारण, हैस्टेलॉय B-3 तार व्यापक रूप से इस्तेमाल किया जाता है:

ग्रेड और मानक

हैस्टेलॉय B-3 तार कठोर अंतर्राष्ट्रीय मानकों का पालन करता है ताकि शीर्ष गुणवत्ता और प्रदर्शन सुनिश्चित हो:

विनिर्माण प्रक्रिया

हेस्टेलॉय B-3 तार के उत्पादन में विकसित मेटलरगीकल तकनीकों का उपयोग किया जाता है ताकि सटीकता और विश्वसनीयता प्राप्त हो:

उपयोगकर्ता की आवश्यकताएँ और संरूपण

हेस्टेलॉय B-3 तार का उपयोग करने वाले उद्योग अक्सर अपनी विशेष आवश्यकताओं को पूरा करने के लिए संरूपित समाधानों की मांग करते हैं। आम संरूपण ये होते हैं:

आमतौर पर पूछे जाने वाले प्रश्न:

डिलीवरी का समय कितना है?

यह ऑर्डर की मात्रा पर निर्भर करता है, छोटे ऑर्डरों के लिए 10-30 दिन। बड़े ऑर्डरों के लिए यह 60 दिन लेता है।

क्या आप OEM/ODM उत्पादन स्वीकार करते हैं?

हाँ! हम OEM/ODM उत्पादन स्वीकार करते हैं। आप हमें अपने नमूने या ड्राइंग भेज सकते हैं।

आप अपने उत्पादों की गुणवत्ता कैसे नियंत्रित करते हैं? क्या उत्पादों के रासायनिक गुण गुणवत्ता मानदंडों को पूरा करते हैं?

पेशेवर गुणवत्ता टीम के साथ, उन्नत उत्पाद गुणवत्ता योजना, कठोर लागू करना और निरंतर सुधार, हम उत्पाद गुणवत्ता जांच प्रमाणपत्र जारी करेंगे, जिसमें रासायनिक विश्लेषण रिपोर्ट शामिल है।

क्या आपकी कंपनी विस्तृत तकनीकी डेटा और ड्राइंग प्रदान कर सकती है?

हाँ, आप कर सकते हैं। कृपया हमें बताएं कि आपको कौन से उत्पाद और अनुप्रयोगों की आवश्यकता है, और हम आपको विस्तृत तकनीकी डेटा और ड्राइंग भेजेंगे ताकि आप उन्हें मूल्यांकन और पुष्टि कर सकें।

आप प्री-सेल और पोस्ट-सेल सेवा कैसे प्रबंधित करते हैं?

हमारे पास एक पेशेवर कारोबारी टीम है जो आपके उत्पाद की आवश्यकताओं को सुरक्षित रखने के लिए एक-से-एक काम करेगी, और यदि आपके कोई सवाल हैं, तो वह आपके लिए उत्तर दे सकता है!

क्या मैं ऑर्डर देने से पहले आपकी कारखाने पर दौरा कर सकता हूँ?

हाँ, आपका आना हमारे लिए स्वागत है। हमें आपसे परिचित होने का अवसर मिलने की खुशी है।

आपका उत्पादन बेस कहाँ है?

हम अपने उत्पाद को चीन, जियांगसू में बनाते हैं और चीन से आपके देश में जल्द से जल्द भेजते हैं, जो आमतौर पर आपकी उत्पाद की आवश्यकताओं और मात्रा पर निर्भर करता है।

क्या आप नमूने भेज सकते हैं?

हाँ, हम भेज सकते हैं।