तेज डिलीवरी ERNiCrMo-4 (C-276) वेल्डिंग तार - थोक ऑर्डर उपलब्ध

अधिक: ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7, ERNi-1, ER70S-6.

हम फैक्ट्री-डायरेक्ट मूल्यों के साथ बड़े पैमाने पर ऑर्डरों पर विशेष छूटें प्रदान करते हैं। चाहे आपको छोटी या बड़ी मात्रा की जरूरत हो, हमारा ERNiCrMo-4 वेल्डिंग तार तुरंत शिपमेंट के लिए उपलब्ध है, जो दुनिया भर के औद्योगिक परियोजनाओं के लिए विश्वसनीय आपूर्ति सुनिश्चित करता है।

- सारांश

- अनुप्रयोग

- पूछे जाने वाले प्रश्न

- अनुशंसित उत्पाद

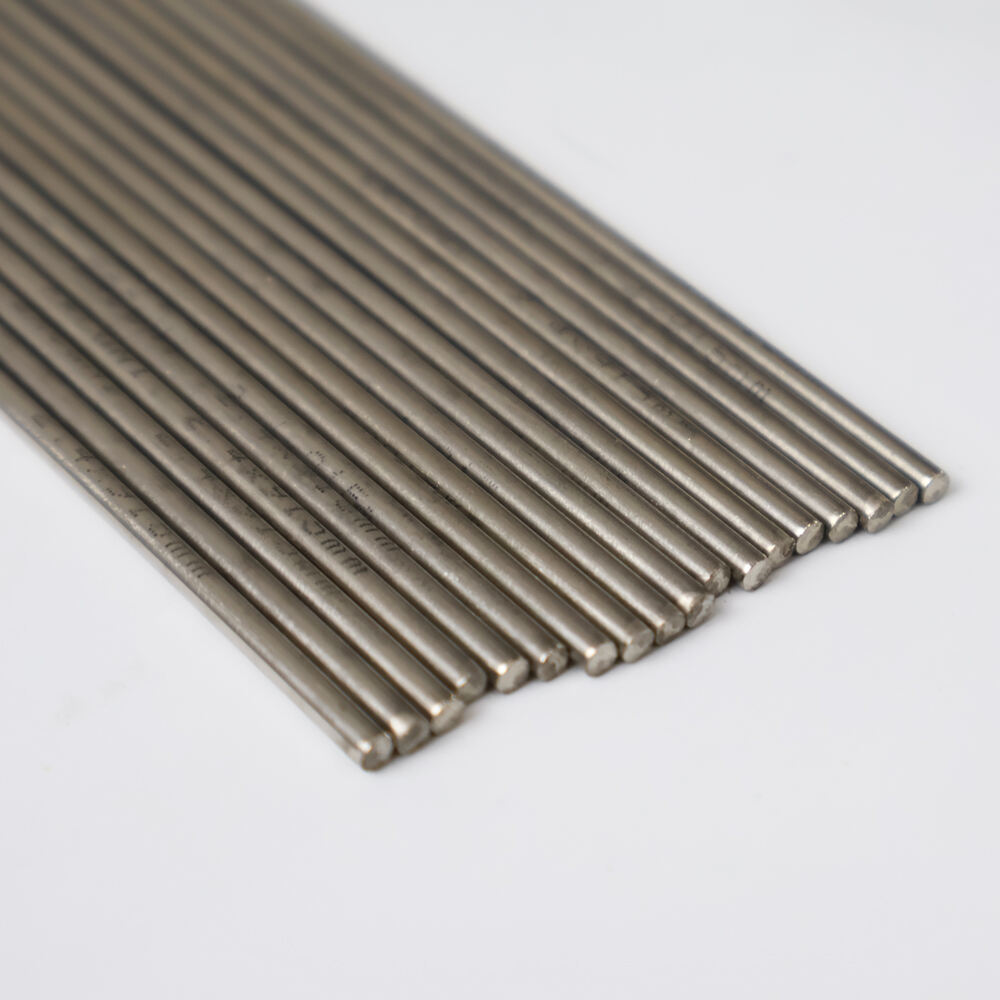

ERNiCrMo-4 (C-276) वेल्डिंग तार एक उच्च-प्रदर्शन आधारित निकेल एल्युमिनियम है जो कठिन औद्योगिक वेल्डिंग अनुप्रयोगों के लिए डिज़ाइन किया गया है। इस एल्युमिनियम का विशेष गुण बहुत अच्छी भेदशीलता प्रतिरोध, उच्च-तापमान बल, और उत्कृष्ट वेल्डिंग क्षमता है, इसलिए यह रसायन विकसित करने, विद्युत संयंत्र, तेल & गैस, समुद्री, और विमान उद्योगों में बहुत उपयोग किया जाता है।

हम थोक ऑर्डर्स के साथ तेज़ प्रस्तावना प्रदान करते हैं, इससे व्यवसाय को प्रतिस्पर्धी फैक्टरी कीमतों पर प्रीमियम-गुणवत्ता वाला वेल्डिंग तार मिलता है। चाहे आपको बड़े पैमाने पर शिपमेंट्स या संवर्द्धित ऑर्डर साइज़ की जरूरत हो, हम विश्वसनीय आपूर्ति और वैश्विक शिपिंग विकल्पों की गारंटी देते हैं।

सामग्री का सार: ERNiCrMo-4 (C-276) वेल्डिंग तार गुण

ERNiCrMo-4 (C-276) एक निकेल-क्रोमियम-मोलिब्डेनम सैंडीशन है, जिसमें लोहा और टंगस्टन का इस्तेमाल किया गया है, जिससे इसकी बदलती परिवेशों में सांद्रण प्रतिरोधकता और दृढ़ता में वृद्धि हुई है। यह वेल्डिंग तार निकेल-आधारित सैंडीशनों और अन्य सांद्रण-प्रतिरोधी धातुओं को जोड़ने के लिए विशेष रूप से डिज़ाइन किया गया है, जिससे यह उच्च-तनाव अनुप्रयोगों के लिए आवश्यक हो जाता है।

ERNiCrMo-4 (C-276) वेल्डिंग तार की मुख्य विशेषताएँ

✔ उत्कृष्ट सांद्रण प्रतिरोधकता – ऑक्सीडाइजिंग और रिड्यूसिंग परिवेश, छेदन और तनाव सांद्रण फटलें रोकने में मदद करती है।

✔ उच्च-तापमान बल – 1093°C (2000°F) तक संरचनात्मक संपूर्णता बनाए रखती है।

✔ उत्कृष्ट वेल्डिंग क्षमता – न्यूनतम गर्म फटने और छिद्रबद्धता के साथ चालाक, दोष-मुक्त वेल्ड बनाता है।

✔ रासायनिक और एसिड प्रतिरोधकता – हाइड्रोक्लोरिक एसिड, सल्फ्यूरिक एसिड, नाइट्रिक एसिड और समुद्री पानी के प्रति सहनशील।

✔ लंबे समय तक की दृढ़ता – चरम औद्योगिक परिस्थितियों में विस्तारित सेवा जीवन प्रदान करती है।

ERNiCrMo-4 उन उद्योगों के लिए प्राथमिक विकल्प है जो उच्च गुणवत्ता वाले, सबजीकरण-प्रतिरोधी वेल्डिंग समाधानों की आवश्यकता रखते हैं।

उद्योग मानक और विनिर्देश

हमारा ERNiCrMo-4 वेल्डिंग तार अंतरराष्ट्रीय उद्योग मानकों को पूरा करता है, जिससे कई क्षेत्रों में अत्यधिक गुणवत्ता, सुरक्षा और संगतता सुनिश्चित होती है।

मानक विनिर्देश

AWS A5.14 ERNiCrMo-4

UNS संख्या N10276

ASTM मानक ASTM B574, ASTM B575

ISO मानक ISO 18274: NiCr15Mo16Fe6W4

ये प्रमाणपत्र यह पुष्टि करते हैं कि हमारा वेल्डिंग तार विश्वसनीय, उच्च-प्रदर्शन और वैश्विक नियमों के अनुरूप है।

ERNiCrMo-4 (C-276) वेल्डिंग तार के अनुप्रयोग

ERNiCrMo-4 वेल्डिंग तार का उपयोग उन उद्योगों में बहुत ज्यादा किया जाता है जहाँ अत्यधिक कोरोशन प्रतिरोधकता और उच्च-तापमान शक्ति की आवश्यकता होती है।

1. रसायन प्रसंस्करण और पेट्रोकेमिकल उद्योग

स्टोरेज टैंक और पाइपलाइन – एसिडिक रसायनों और तीखे सॉल्वेंट्स से सुरक्षा प्रदान करता है।

हीट एक्सचेंजर और रिएक्टर – उच्च-तापमान संचालन में कोरोशन प्रतिरोधकता प्रदान करता है।

पंप और वैल्व – रसायन प्रसंस्करण प्रणालियों में लंबे समय तक कार्यक्षमता सुनिश्चित करता है।

ऊर्जा क्षेत्र और पावर प्लांट

बोयलर और हीट एक्सचेंजर – अत्यधिक गर्मी और दबाव का सामना कर सकते हैं।

फ्लू गैस डेसल्फराइज़ेशन (FGD) प्रणाली – उत्सर्जन नियंत्रण प्रणालियों में एसिडिक कोरोशन से बचाता है।

परमाणु रिएक्टर घटक – रेडिएशन और थर्मल तनाव से प्रतिरोधी है।

3. तेल और गैस उद्योग

ऑफशोर ड्रिलिंग प्लेटफार्म और पाइपलाइन – सल्फाइड स्ट्रेस क्रैकिंग (SSC) और हाइड्रोजन ब्रिट्टलनेस से बचाता है।

LNG स्टोरेज और प्रसंस्करण इकाइयाँ – क्रायोजेनिक स्थितियों में स्थिरता बनाए रखता है।

रिफाइनरी उपकरण और कैटलिस्टिक क्रैकिंग यूनिट - उच्च-तापमान से होने वाले सं Ghishan से बचाता है।

4. मारीन और एरोस्पेस इंजीनियरिंग

समुद्री पानी की हीट एक्सचेंजर और जहाज निर्माण - नमकीन पानी के सं Ghishan से अधिकतम प्रतिरोध प्रदान करता है।

जेट इंजन घटक और एरोस्पेस संरचना - उच्च-तापमान ऑक्सीकरण प्रतिरोध प्रदान करता है।

5. भोजन संसाधन और फार्मेसूटिकल उद्योग

स्टरिलाइज़ेशन उपकरण और स्वच्छ पाइपिंग - सं Ghishan मुक्त और प्रदूषण मुक्त प्रदर्शन का विश्वास दिलाता है।

हमारे ERNiCrMo-4 (C-276) वेल्डिंग तार क्यों चुनें?

तेज डिलीवरी और बड़े पैमाने पर उपलब्धता - बड़े ऑर्डरों के लिए तुरंत शिपिंग।

फैक्ट्री डायरेक्ट प्राइसिंग - प्रीमियम-गुणवत्ता वाले वेल्डिंग तार पर थोक छूट प्राप्त करें।

वैश्विक शिपिंग - विश्वभर के ग्राहकों तक विश्वसनीय डिलीवरी।

गैरोंटीकृत उच्च-गुणवत्ता सामग्री – AWS, ASTM और ISO मानकों को पूरा करती है।

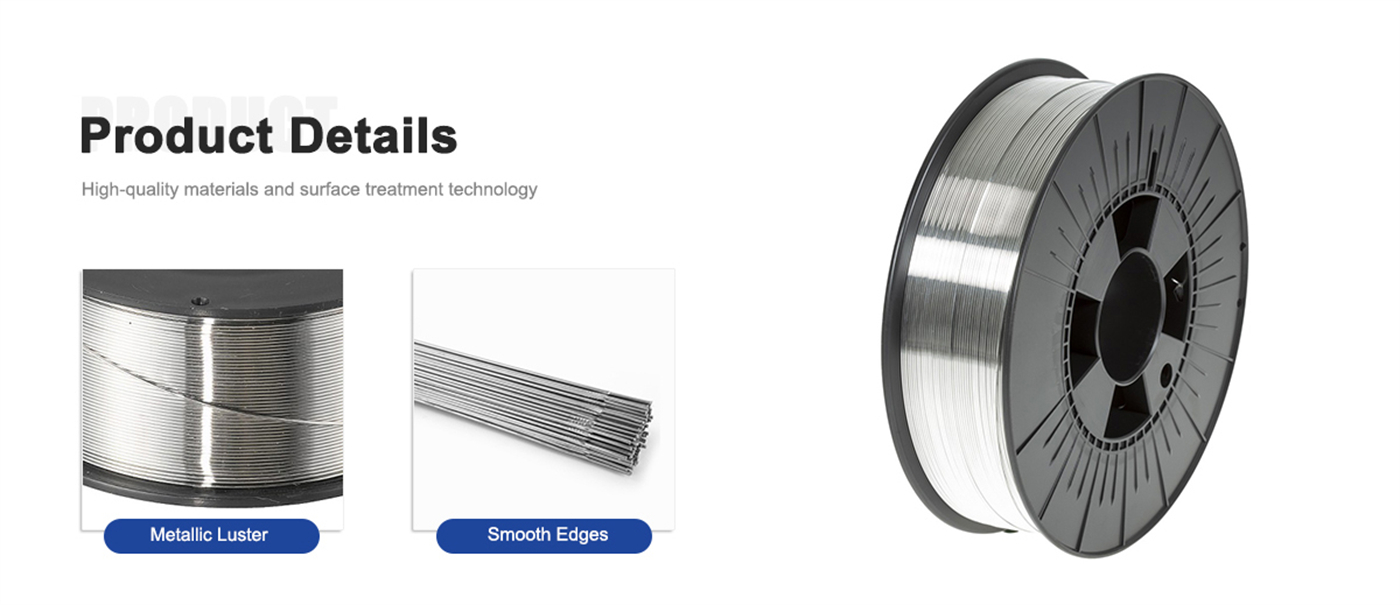

सेवा आदेश विकल्प – स्पूल्स, कोइल और कट-टू-लेंग्थ आकार में उपलब्ध।

निश्चित स्टॉक उपलब्धता – तेज़ डिस्पैच के लिए हमेशा तैयार।

आमतौर पर पूछे जाने वाले प्रश्न:

डिलीवरी का समय कितना है?

यह ऑर्डर की मात्रा पर निर्भर करता है, छोटे ऑर्डरों के लिए 10-30 दिन। बड़े ऑर्डरों के लिए यह 60 दिन लेता है।

क्या आप OEM/ODM उत्पादन स्वीकार करते हैं?

हाँ! हम OEM/ODM उत्पादन स्वीकार करते हैं। आप हमें अपने नमूने या ड्राइंग भेज सकते हैं।

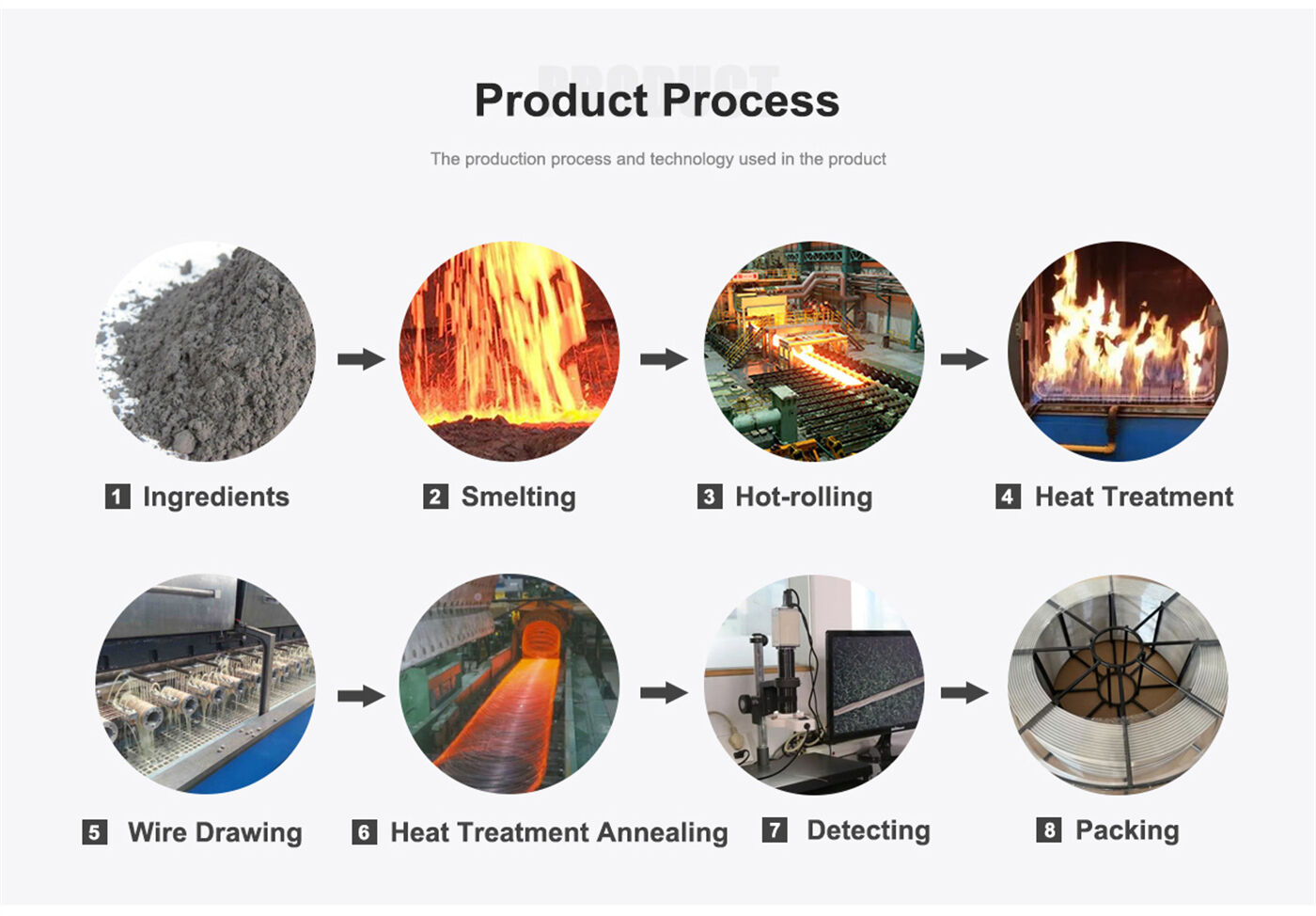

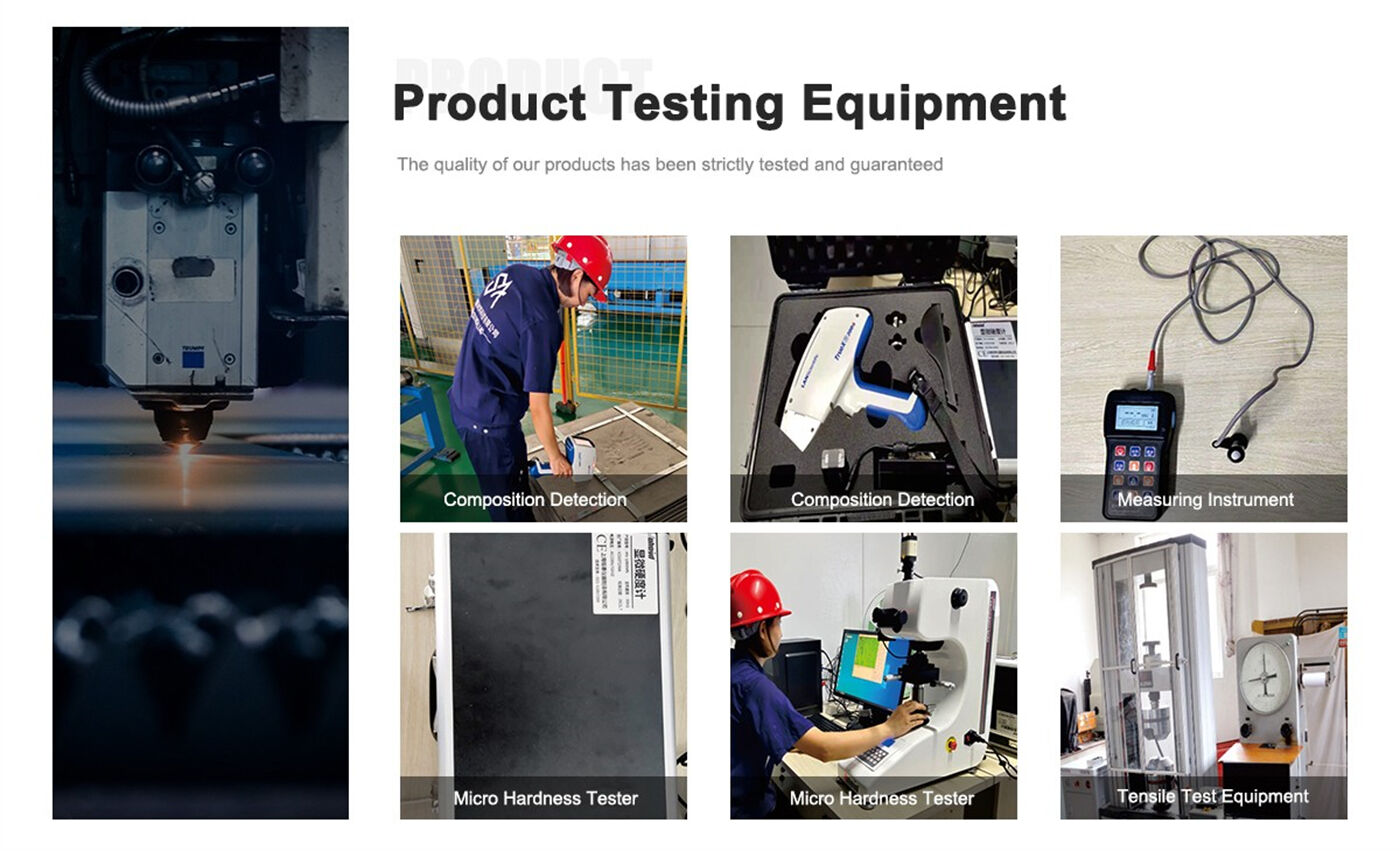

आप अपने उत्पादों की गुणवत्ता कैसे नियंत्रित करते हैं? क्या उत्पादों के रासायनिक गुण गुणवत्ता मानदंडों को पूरा करते हैं?

पेशेवर गुणवत्ता टीम के साथ, उन्नत उत्पाद गुणवत्ता योजना, कठोर लागू करना और निरंतर सुधार, हम उत्पाद गुणवत्ता जांच प्रमाणपत्र जारी करेंगे, जिसमें रासायनिक विश्लेषण रिपोर्ट शामिल है।

क्या आपकी कंपनी विस्तृत तकनीकी डेटा और ड्राइंग प्रदान कर सकती है?

हाँ, आप कर सकते हैं। कृपया हमें बताएं कि आपको कौन से उत्पाद और अनुप्रयोगों की आवश्यकता है, और हम आपको विस्तृत तकनीकी डेटा और ड्राइंग भेजेंगे ताकि आप उन्हें मूल्यांकन और पुष्टि कर सकें।

आप प्री-सेल और पोस्ट-सेल सेवा कैसे प्रबंधित करते हैं?

हमारे पास एक पेशेवर कारोबारी टीम है जो आपके उत्पाद की आवश्यकताओं को सुरक्षित रखने के लिए एक-से-एक काम करेगी, और यदि आपके कोई सवाल हैं, तो वह आपके लिए उत्तर दे सकता है!

क्या मैं ऑर्डर देने से पहले आपकी कारखाने पर दौरा कर सकता हूँ?

हाँ, आपका आना हमारे लिए स्वागत है। हमें आपसे परिचित होने का अवसर मिलने की खुशी है।

आपका उत्पादन बेस कहाँ है?

हम अपने उत्पाद को चीन, जियांगसू में बनाते हैं और चीन से आपके देश में जल्द से जल्द भेजते हैं, जो आमतौर पर आपकी उत्पाद की आवश्यकताओं और मात्रा पर निर्भर करता है।

क्या आप नमूने भेज सकते हैं?

हाँ, हम भेज सकते हैं।