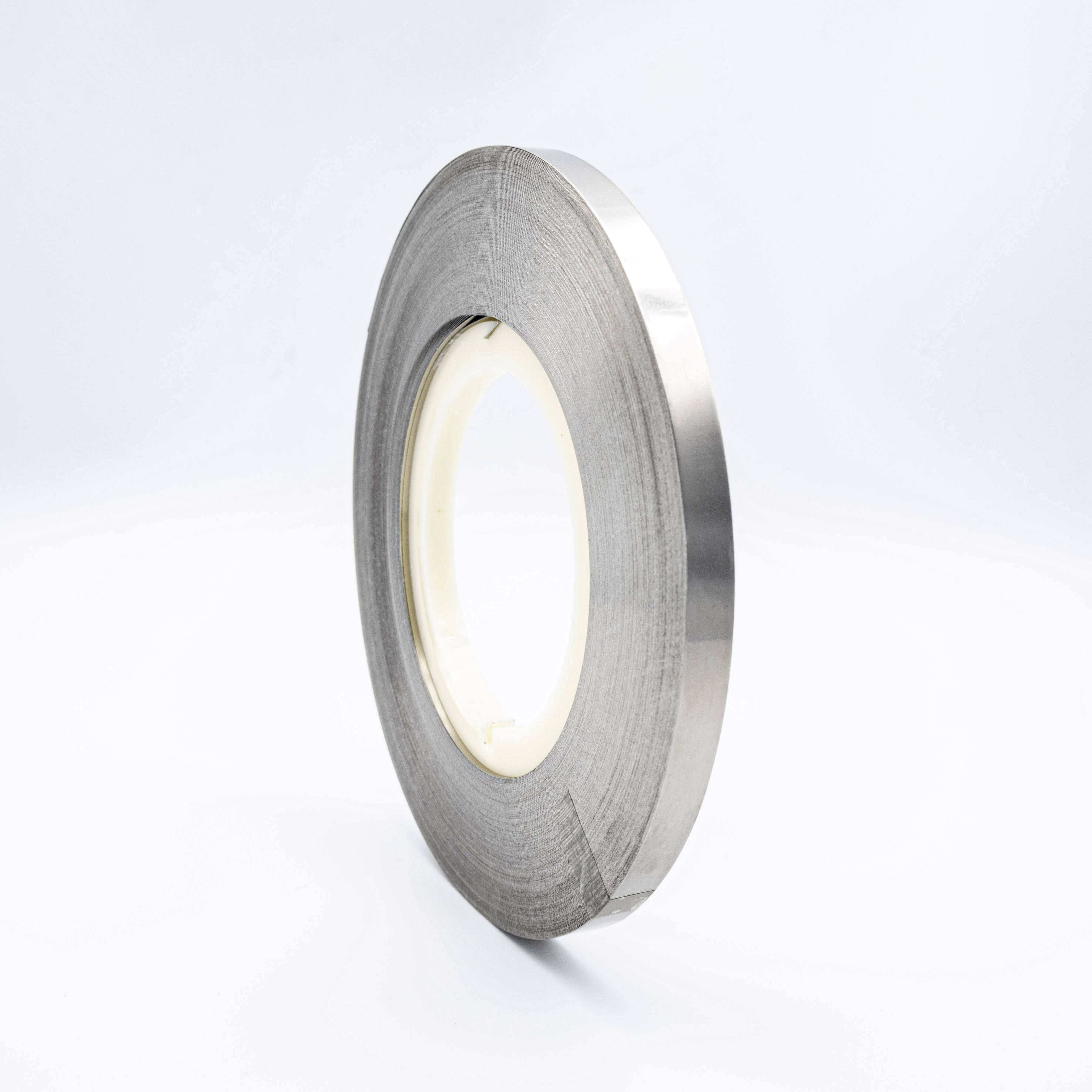

सर्वश्रेष्ठ गुणवत्ता की मोनेल K500 स्ट्रिप्स – उच्च-प्रदर्शन अनुप्रयोगों के लिए डिज़ाइन किए गए

हम फैक्ट्री डायरेक्ट कीमतों और बड़े पैमाने पर ऑर्डर के लिए विशेष छूट प्रदान करते हैं। चाहे आपको छोटी या बड़ी मात्रा में उत्पाद चाहिए, हमारे उत्पाद जल्दी भेजे जाते हैं ताकि विश्वभर के औद्योगिक परियोजनाओं के लिए विश्वसनीय आपूर्ति सुनिश्चित हो।

- सारांश

- विनिर्देश

- अनुप्रयोग

- पूछे जाने वाले प्रश्न

- अनुशंसित उत्पाद

-

उच्च ताकत और कठोरता: उच्च तापमान पर भी अपनी मैकेनिकल ताकत को बनाए रखता है।

-

विशिष्ट धावकता प्रतिरोध: समुद्री पानी, एसिड और कड़े रासायनिक परिवेश का प्रतिरोध करता है।

-

अ-चुंबकीय गुण: विशिष्ट परिस्थितियों में अ-चुंबकीय विशेषताओं को बनाए रखता है।

-

अच्छी वेल्डिंग और मशीनिंग क्षमता: मानक वेल्डिंग और मशीनिंग तकनीकों का उपयोग करके बनाया जा सकता है।

-

समुद्री इंजीनियरिंग: जहाज़ बनाने, अफ़्तरशॉर ड्रिलिंग और समुद्री पानी पंप घटकों में उपयोग किया जाता है।

-

रासायनिक प्रसंस्करण: रासायनिक इकाइयों में अम्लीय और धावक रासायनिक पदार्थों को प्रबंधित करने के लिए आदर्श है।

-

विमान उद्योग: टर्बाइन ब्लेड, इंजन घटकों और उच्च ताकत के फ़ास्टनर्स में उपयोग किया जाता है।

-

ओइल एंड गैस क्षेत्र: वैल्व घटकों, डाउनहोल टूल्स और ड्रिलिंग उपकरणों में लगाया जाता है।

-

चिकित्सा उपकरण: अ-चुंबकीय और धावकता प्रतिरोध की आवश्यकता वाले सटीक उपकरणों में उपयोग किया जाता है।

-

ASTM B127⁄ ASTM B865

-

यूएनएस एन05500

-

AMS 4676⁄ AMS 4679

-

ISO और DIN समतुल्य मानक

-

गलन और एल्योइ बनाना: कच्चे माल को एक समान एल्योइ की संरचना प्राप्त करने के लिए वैक्यूम या इंडक्शन फर्नेस में गलाया जाता है।

-

गर्मी और ठंडी रोलिंग: धातु को नियंत्रित मोटाई और सतह पूर्ण के साथ पतली फ़िल्मों में रोल किया जाता है।

-

समाधान उपचार: गर्मी का उपचार द्वितीयक चरणों को घोलने और रिक्तिका को सजातीकृत करने के लिए लागू किया जाता है।

-

वय (प्रस्फोटन कठोरता): सामग्री को इसकी शक्ति और कठोरता को बढ़ाने के लिए वय किया जाता है।

-

पिकलिंग और सतह उपचार: फिल्मों को ऑक्साइड्स को हटाने और धावन प्रतिरोध को बढ़ाने के लिए रासायनिक सफाई की जाती है।

-

अंतिम जाँच और परीक्षण: गुणवत्ता नियंत्रण उपाय आयाम जाँच, यांत्रिक गुण परीक्षण, और बदली प्रतिरोध मूल्यांकन शामिल हैं।

-

सटीक आयाम: अनुप्रयोग की जरूरतों के अनुसार चौड़ाई, मोटाई, और लंबाई का समायोजन।

-

सतह पूर्णता विकल्प: विभिन्न औद्योगिक उपयोगों के लिए पोलिश किए, ब्रश किए, या कोट किए फिनिश प्रदान करना।

-

सख्त अनुमति और सटीक कटिंग: उच्च-प्रदर्शन अनुप्रयोगों के लिए फिल्मों को सख्त आयामी सटीकता का पालन करना।

-

सर्टिफिकेशन और सदृशता: परीक्षण रिपोर्टों और उद्योग मानकों की सदृशता के साथ सामग्री पहुँचाना।

मोनेल K500 एक प्रतिसारण-कठोरता धातु मिश्रण है, जिसे अपनी उत्कृष्ट ताकत, संज्ञानाभिक्षा प्रतिरोधकता और डूबे हुए दृढ़ता के लिए जाना जाता है। चुनौतीपूर्ण औद्योगिक अनुप्रयोगों के लिए डिज़ाइन किया गया, मोनेल K500 स्ट्रिप्स का व्यापक उपयोग मारीन, रसायन, विमाननाविकी, और तेल और गैस उद्योगों में उनकी उत्कृष्ट यांत्रिक गुणों और कड़वे पर्यावरणों के प्रति प्रतिरोध के कारण किया जाता है। यह लेख मोनेल K500 स्ट्रिप्स के सामग्री, अनुप्रयोग, ग्रेड, निर्माण प्रक्रियाओं और ग्राहकों की मांगों पर चर्चा करता है।

सामग्री संघटन और गुण

मोनेल K500 एक निकेल-कॉपर एलॉय है जिसमें प्रतिस्थापन कठोरता के लिए बढ़ी शक्ति के लिए छोटी मात्रा में एल्यूमिनियम और टाइटेनियम शामिल है। मोनेल K500 के मुख्य गुण निम्नलिखित हैं:

मोनेल K500 स्ट्रिप्स के अनुप्रयोग

मोनेल K500 स्ट्रिप्स का उपयोग विभिन्न उद्योगों में बहुत ज्यादा किया जाता है क्योंकि इनकी मजबूती और चरम परिस्थितियों का सामना करने की क्षमता होती है। सामान्य अनुप्रयोग इन्हें शामिल करते हैं:

ग्रेड और विन्यास

मोनेल K500 स्ट्रिप्स को गुणवत्ता और विश्वसनीयता की गारंटी के लिए अंतर्राष्ट्रीय मानकों और विनिर्देशिकाओं के अनुसार बनाया जाता है। कुछ सामान्य ग्रेड्स और विनिर्देशिकाएं इन्हें शामिल करती हैं:

विनिर्माण प्रक्रिया

मोनेल K500 स्ट्रिप्स का उत्पादन वांछित यांत्रिक और रासायनिक गुणों को प्राप्त करने के लिए एक सटीक और नियंत्रित विनिर्माण प्रक्रिया को शामिल करता है। मुख्य कदम इन्क्लूड हैं:

ग्राहकों की जरूरतों का पूरा करना

उच्च-गुणवत्ता वाले मोनेल K500 स्ट्रिप्स की तलाश करने वाले ग्राहकों के पास निर्माताओं को पूरा करना चाहिए विशिष्ट आवश्यकताएँ होती हैं। ये शामिल हैं:

आमतौर पर पूछे जाने वाले प्रश्न:

डिलीवरी का समय कितना है?

यह ऑर्डर की मात्रा पर निर्भर करता है, छोटे ऑर्डरों के लिए 10-30 दिन। बड़े ऑर्डरों के लिए यह 60 दिन लेता है।

क्या आप OEM/ODM उत्पादन स्वीकार करते हैं?

हाँ! हम OEM/ODM उत्पादन स्वीकार करते हैं। आप हमें अपने नमूने या ड्राइंग भेज सकते हैं।

आप अपने उत्पादों की गुणवत्ता कैसे नियंत्रित करते हैं? क्या उत्पादों के रासायनिक गुण गुणवत्ता मानदंडों को पूरा करते हैं?

पेशेवर गुणवत्ता टीम के साथ, उन्नत उत्पाद गुणवत्ता योजना, कठोर लागू करना और निरंतर सुधार, हम उत्पाद गुणवत्ता जांच प्रमाणपत्र जारी करेंगे, जिसमें रासायनिक विश्लेषण रिपोर्ट शामिल है।

क्या आपकी कंपनी विस्तृत तकनीकी डेटा और ड्राइंग प्रदान कर सकती है?

हाँ, आप कर सकते हैं। कृपया हमें बताएं कि आपको कौन से उत्पाद और अनुप्रयोगों की आवश्यकता है, और हम आपको विस्तृत तकनीकी डेटा और ड्राइंग भेजेंगे ताकि आप उन्हें मूल्यांकन और पुष्टि कर सकें।

आप प्री-सेल और पोस्ट-सेल सेवा कैसे प्रबंधित करते हैं?

हमारे पास एक पेशेवर कारोबारी टीम है जो आपके उत्पाद की आवश्यकताओं को सुरक्षित रखने के लिए एक-से-एक काम करेगी, और यदि आपके कोई सवाल हैं, तो वह आपके लिए उत्तर दे सकता है!

क्या मैं ऑर्डर देने से पहले आपकी कारखाने पर दौरा कर सकता हूँ?

हाँ, आपका आना हमारे लिए स्वागत है। हमें आपसे परिचित होने का अवसर मिलने की खुशी है।

आपका उत्पादन बेस कहाँ है?

हम अपने उत्पाद को चीन, जियांगसू में बनाते हैं और चीन से आपके देश में जल्द से जल्द भेजते हैं, जो आमतौर पर आपकी उत्पाद की आवश्यकताओं और मात्रा पर निर्भर करता है।

क्या आप नमूने भेज सकते हैं?

हाँ, हम भेज सकते हैं।