Heat-Resistant Inconel 718 Sheet – Engineered for Extreme Temperature Conditions

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Aerospace – Jet Engine Components: The aerospace industry is one of the primary sectors where Inconel 718 sheet plays a vital role. In jet engines, turbine blades, rotor blades, and combustion chambers are subjected to extremely high temperatures and pressures. Inconel 718 sheet offers exceptional performance in these environments, ensuring that components maintain their strength and performance at high operational temperatures. Its resistance to thermal fatigue and oxidation is crucial for long-term reliability in the demanding conditions of jet propulsion systems.

-

Rocket Motors and Propulsion Systems: In the space industry, Inconel 718 sheet is used in rocket engines and propulsion systems that operate under both high temperatures and extreme mechanical stresses. Components such as combustion chambers, nozzle extensions, and cooling ducts made from Inconel 718 benefit from its ability to withstand thermal expansion, thermal cycling, and high-pressure environments. The alloy's high tensile strength and resistance to thermal creep ensure the integrity of these components during launches and space missions.

-

Gas Turbines: Inconel 718 sheet is a go-to material for gas turbines used in power generation and industrial processes. The sheet is employed to make critical components like turbine blades, rotors, and casings, all of which must perform reliably under high heat and pressure conditions. Inconel 718’s ability to resist oxidation, thermal fatigue, and creep under these extreme conditions is essential for maintaining the efficiency and longevity of gas turbines, contributing to the consistent production of energy.

-

Chemical Processing Equipment: Inconel 718 sheet is also used in the chemical processing industry where materials must withstand not only high temperatures but also aggressive chemical environments. The sheet can be used in reactors, heat exchangers, and pressure vessels that handle corrosive chemicals at elevated temperatures. The excellent resistance to pitting, crevice corrosion, and oxidation ensures that components made from Inconel 718 sheet remain functional and durable over time, even under harsh processing conditions.

-

Power Plant Equipment: Power plants require materials that can withstand the high temperatures generated by turbines and other components. Inconel 718 sheet is commonly used in the manufacturing of heat exchangers, casings, and high-stress components of power plants that need to maintain structural integrity at elevated temperatures. Its superior thermal stability allows these components to perform efficiently without succumbing to thermal degradation.

-

Marine and Offshore Applications: Inconel 718 sheet is used in marine turbines and other offshore applications, where high pressure and temperature conditions are combined with exposure to corrosive seawater. Its excellent resistance to both heat and corrosion makes it a reliable material for these harsh environments, ensuring the longevity of critical components used in energy extraction from the sea.

-

UNS N07718: This is the standard designation for Inconel 718, which is widely used for applications that require exceptional high-temperature performance. UNS N07718 sheet is known for its ability to resist thermal fatigue and oxidation at temperatures above 700°C, making it ideal for aerospace, power generation, and cryogenic applications.

-

AMS 5596: This specification covers Inconel 718 sheet used in aerospace applications. It is typically used in components like turbine blades and engine parts, where the material’s strength, fatigue resistance, and oxidation resistance at high temperatures are critical.

-

AMS 5590: This specification is for Inconel 718 sheet used in high-performance applications like jet engines, gas turbines, and rocket propulsion systems. The alloy is designed to withstand extreme temperatures and mechanical stresses while retaining its strength and structural integrity.

-

DIN 2.4668: The European equivalent of UNS N07718, this grade is used for high-temperature applications in industries such as aerospace, power generation, and chemical processing. It provides excellent resistance to oxidation and creep at elevated temperatures.

-

Melting and Alloying: The first step in producing Inconel 718 sheet is melting the base metals, including nickel, chromium, molybdenum, niobium, and titanium, in a vacuum induction or electric arc furnace. This process ensures precise control over the alloy’s composition, which is crucial for achieving the desired mechanical properties and resistance to high temperatures.

-

Casting: Once the alloy is melted, it is cast into large billets or ingots, which are further processed into thinner forms. Casting ensures that the material has a uniform structure and composition, which is necessary to maintain strength and resistance to fatigue during use.

-

Hot Rolling and Sheet Formation: The next step is hot rolling the cast billets into sheets of the desired thickness. Hot rolling is done at high temperatures to refine the grain structure, improve the material’s strength, and prepare it for further processing. The rolling process also ensures that the sheet maintains uniform thickness and consistency throughout.

-

Heat Treatment: After rolling, Inconel 718 sheet undergoes a heat treatment process that includes solution annealing followed by aging. Solution annealing helps to relieve internal stresses and homogenize the microstructure, while aging further strengthens the alloy by precipitating fine particles that enhance the material's strength and resistance to thermal creep and oxidation.

-

Finishing and Inspection: Once the heat treatment is completed, the Inconel 718 sheet is polished or surface-finished to ensure a smooth and defect-free surface. The material undergoes strict quality control measures, including dimensional checks, surface inspections, and non-destructive tests (e.g., ultrasonic testing, eddy current testing) to detect any potential flaws that could affect performance. The sheet is then certified to meet the relevant industry specifications.

-

High Strength and Durability: The sheet must exhibit high tensile strength, particularly in environments where components are subjected to mechanical stresses and high temperatures. Users in industries like aerospace and power generation require a material that can maintain its structural integrity over time, even in challenging operating conditions.

-

High-Temperature Resistance: Components exposed to elevated temperatures—such as in jet engines or gas turbines—require a material that can withstand heat without losing its strength. Inconel 718 sheet is engineered to resist thermal creep, oxidation, and thermal fatigue at temperatures above 700°C, making it ideal for high-temperature applications.

-

Oxidation and Corrosion Resistance: In industries such as chemical processing and marine applications, Inconel 718 sheet must provide resistance to oxidation and corrosion, especially when exposed to harsh chemical environments or seawater. The alloy’s ability to resist pitting and crevice corrosion ensures its longevity in these corrosive conditions.

-

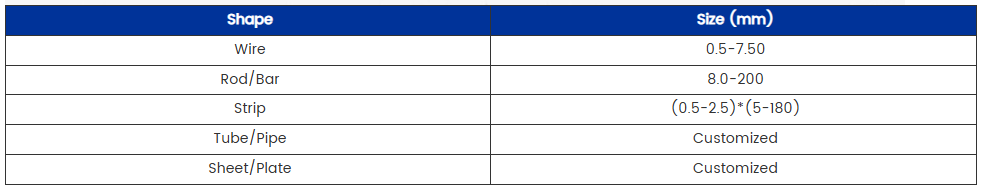

Dimensional Precision: For critical applications, such as turbine blades or aerospace components, users demand high dimensional precision to ensure proper fit and function. Inconel 718 sheet is manufactured to tight tolerances, ensuring that components meet the required specifications for both mechanical performance and size.

-

Weldability and Fabrication Flexibility: Inconel 718 sheet should be easily weldable and adaptable to various fabrication methods. The material's good weldability ensures that it can be incorporated into complex assemblies without compromising its performance.

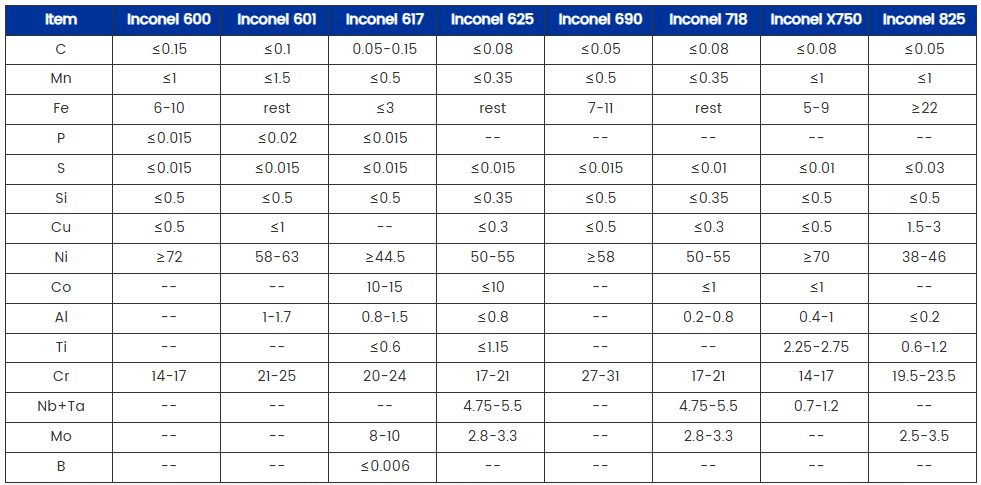

Inconel 718 is a high-performance nickel-chromium superalloy known for its exceptional strength, resistance to oxidation and corrosion, and superior performance under extreme temperature conditions. The alloy is primarily composed of nickel (50-55%), chromium (17-21%), and other elements such as molybdenum, niobium, and titanium, which give it remarkable mechanical properties at both elevated and cryogenic temperatures.

The Inconel 718 sheet is designed for critical applications where high heat resistance is paramount. This material is engineered to maintain its mechanical strength, oxidation resistance, and structural integrity at temperatures exceeding 700°C (1290°F), making it ideal for components that experience extreme thermal stresses. It is commonly used in aerospace, power generation, and industrial applications where high temperatures, thermal fatigue, and mechanical stresses are common.

Applications of Heat-Resistant Inconel 718 Sheet

Grade & Specifications

Inconel 718 sheet is produced according to various industry specifications to meet the demands of high-performance applications. Some key grades and specifications include:

Manufacturing Process of Inconel 718 Sheet

The manufacturing of Inconel 718 sheet involves several key processes designed to achieve the desired material properties, such as high strength, heat resistance, and dimensional precision. These steps ensure that the sheet meets the strict performance standards required for its end-use applications.

User Requirements

Users of Inconel 718 sheet typically require materials that can perform under extreme conditions. Some of the key user demands for Inconel 718 sheet include:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.