Hastelloy C-276 Round Bars – Ultimate Strength for Aerospace & Marine

We offer factory direct pricing and special discounts for bulk orders. Whether you need small or large quantities, our products are shipped quickly to ensure a reliable supply for industrial projects worldwide.

- Overview

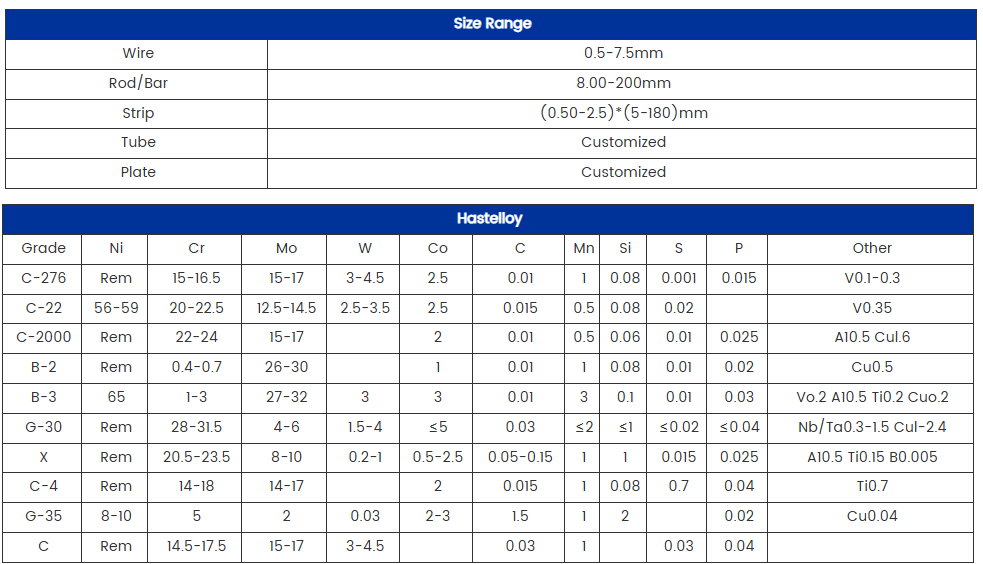

- Specification

- Applications

- FAQs

- Recommended Products

Introduction to Hastelloy C-276 Round Bars

Hastelloy C-276 round bars are highly sought-after in the aerospace and marine industries due to their excellent mechanical strength, corrosion resistance, and ability to perform under extreme environmental conditions. These round bars are used in various critical applications where standard stainless steels fail to provide adequate durability.

Material Properties

Hastelloy C-276 is a nickel-molybdenum-chromium superalloy designed to resist pitting, crevice corrosion, and stress corrosion cracking. The addition of molybdenum and tungsten enhances its corrosion resistance, making it suitable for harsh environments.

Applications of Hastelloy C-276 Round Bars

Aerospace Industry: Used in jet engines, turbine blades, exhaust ducts, and structural components exposed to high temperatures and corrosive conditions.

Marine Applications: Ideal for shipbuilding, offshore drilling platforms, and seawater handling systems due to its superior seawater corrosion resistance.

Chemical Processing: Essential for heat exchangers, reaction vessels, and piping systems exposed to strong acids and oxidizing agents.

Power Plants: Used in heat-resistant structures within nuclear and fossil fuel power plants.

Medical Equipment: Applied in specialized surgical tools and implants requiring biocompatibility and corrosion resistance.

Manufacturing Process

Hastelloy C-276 round bars are manufactured through a precise process that ensures their strength and durability:

Melting & Alloying: The raw materials are melted in a vacuum or electric furnace to ensure purity.

Casting & Forging: The alloy is cast and then forged into cylindrical shapes to achieve desired mechanical properties.

Heat Treatment: Solution annealing enhances its mechanical strength and corrosion resistance.

Cold & Hot Working: Further processing refines the bar’s surface and dimensions.

Quality Inspection: Each round bar undergoes rigorous testing, including ultrasonic, chemical, and mechanical tests, to meet ASTM B574 standards.

User Demand & Market Trends

The demand for Hastelloy C-276 round bars is growing due to:

High Durability & Strength: Preferred for high-stress applications in aerospace and marine industries.

Global Compliance: Meets international quality standards such as ASTM, ASME, and NACE.

Customization & Bulk Orders: Available in various diameters and lengths to suit industrial requirements.

Cost-Effectiveness: Competitive pricing for bulk supply and OEM customization.

Conclusion

Hastelloy C-276 round bars are an excellent choice for aerospace, marine, and industrial applications requiring superior corrosion resistance and mechanical strength. With a robust supply chain and strict quality control measures, these round bars continue to be a reliable material for critical industries worldwide.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.