GH36 High-Temperature Alloy for Aircraft Engine Components & Gas Turbines

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- About Us

- FAQs

- Recommended Products

- Turbine Blades: One of the most critical components in both aircraft engines and gas turbines, turbine blades experience extreme temperatures and high rotational forces. GH36’s excellent strength retention at elevated temperatures ensures these blades can withstand the intense operational stresses without deforming or failing, ensuring smooth and reliable engine performance.

- Turbine Discs: Turbine discs, which support the turbine blades, must also withstand high temperatures and mechanical loads. GH36 is commonly used in turbine discs due to its ability to maintain structural integrity under heat and stress, ensuring the safe operation of engines at peak efficiency.

- Combustion Chambers: The combustion chamber is where the fuel is ignited, creating temperatures that are critical to the engine’s overall performance. GH36’s resistance to oxidation and creep deformation makes it a go-to material for components exposed to these harsh conditions, contributing to longer lifespans and greater engine efficiency.

- Nozzles and Exhaust Components: In both aircraft engines and industrial gas turbines, the nozzles and exhaust components must tolerate extremely high heat. GH36 provides exceptional performance in these components, offering resistance to thermal fatigue, oxidation, and corrosion, which enhances the reliability and longevity of the exhaust systems.

- Heat Exchangers: In gas turbine power plants, heat exchangers play a vital role in maintaining temperature efficiency. GH36’s high thermal conductivity and resistance to oxidation ensure these components can function effectively under high-stress conditions.

- High-Temperature Strength: GH36 retains its strength at elevated temperatures, typically ranging from 600°C to 1,000°C, making it ideal for applications in which materials are exposed to intense heat for extended periods.

- Oxidation and Corrosion Resistance: As aircraft engines and gas turbines operate in environments where components are exposed to high-temperature gases, GH36’s excellent oxidation resistance prevents the degradation of critical parts, contributing to long-term durability and reliability.

- Creep Resistance: One of the key challenges in high-temperature applications is the deformation of materials under constant stress. GH36’s resistance to creep ensures that components, such as turbine blades and discs, maintain their shape and strength even after prolonged exposure to high pressures and temperatures.

- Thermal Fatigue Resistance: In aircraft engines and turbines, components frequently undergo thermal cycling, with rapid heating and cooling. GH36’s ability to resist thermal fatigue ensures that it can endure these temperature variations without cracking or losing its mechanical properties.

- High-Temperature Fatigue Strength: GH36’s superior high-temperature fatigue strength helps prevent cracks and other forms of degradation that can compromise the integrity of engine parts, particularly in high-stress components like turbine blades.

- Enhanced Performance and Efficiency: By using GH36 in critical components like turbine blades and discs, engine and turbine manufacturers can ensure better performance, improved fuel efficiency, and optimized energy production. The alloy’s high-temperature strength and corrosion resistance contribute to more reliable engine operation.

- Increased Durability and Reliability: GH36’s resistance to oxidation, creep, and thermal fatigue ensures that components last longer, reducing the need for frequent maintenance or replacement and improving the overall reliability of engines and turbines.

- Reduced Maintenance Costs: As a result of its durability, GH36 helps to reduce maintenance and replacement costs. Aircraft engines and gas turbines that utilize GH36 components experience fewer failures, which translates to less downtime and more efficient operations.

- Safety and Structural Integrity: In the high-stakes environment of aerospace and power generation, safety is a top priority. GH36’s ability to maintain its strength and resist damage in extreme conditions ensures the structural integrity of vital engine and turbine components, enhancing both safety and performance.

- Cost-Effective Long-Term Solution: While GH36 may come at a higher initial cost than some traditional materials, its exceptional performance and long lifespan provide cost savings over time. Reduced maintenance, fewer replacements, and greater reliability contribute to a lower total cost of ownership.

In the aerospace and power generation industries, materials need to withstand extreme temperatures and high stresses without compromising on strength, durability, or efficiency. One such material that excels in these challenging environments is the GH36 high-temperature alloy. A key player in the development of modern aircraft engine components and gas turbines, GH36 provides superior performance in both high-temperature and high-pressure conditions. Known for its remarkable mechanical properties, GH36 plays a pivotal role in ensuring the efficiency, reliability, and safety of aircraft engines and gas turbines.

Applications of GH36 in Aircraft Engines & Gas Turbines

GH36 is specifically designed to perform in the most demanding environments where temperatures can reach up to 1,000°C and beyond. Some of its key applications include:

Key Properties of GH36 High-Temperature Alloy

The outstanding performance of GH36 in aircraft engines and gas turbines is due to its unique combination of mechanical properties, including:

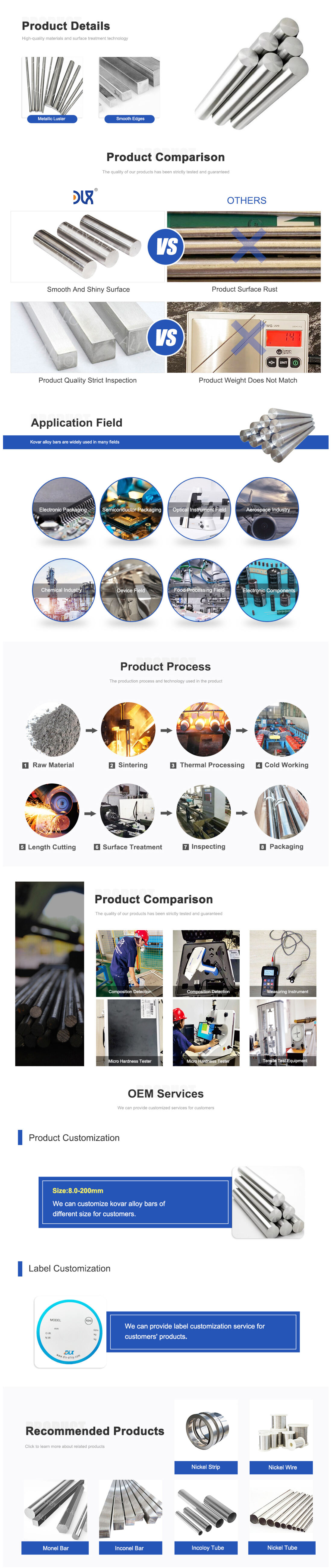

Meeting Customer Needs in Aerospace & Power Generation

The aerospace and power generation industries require materials that not only perform well but also meet specific safety, longevity, and operational requirements. GH36 addresses these needs by providing several key benefits for manufacturers and operators:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

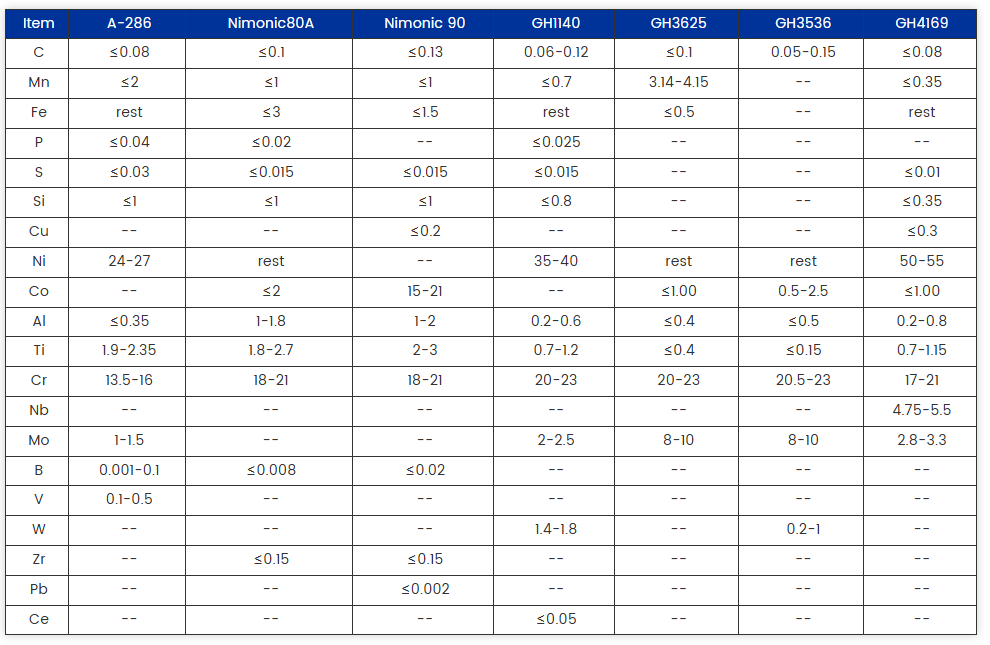

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.