GH2901 High-Performance Nickel-Based Alloy for Aerospace and High-Pressure Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

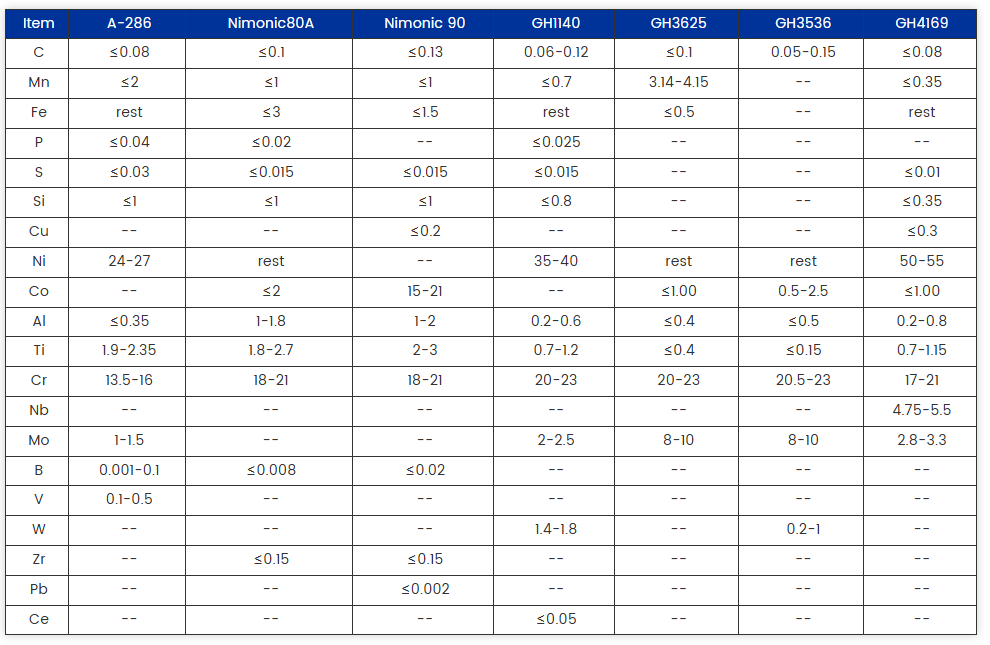

- Specification

- About Us

- FAQs

- Recommended Products

- Turbine Blades and Discs: In aerospace engines, turbine blades and discs are subjected to high temperatures, centrifugal forces, and combustion gases. GH2901’s ability to maintain its strength and resist thermal creep makes it an ideal choice for these components. Its high resistance to oxidation ensures that parts exposed to hot gases remain durable and maintain their integrity throughout the engine’s life.

- Exhaust Systems and Heat Shields: Aerospace vehicles, particularly space shuttles and reentry vehicles, face extreme temperatures during launch and re-entry. GH2901’s thermal stability and resistance to oxidation make it an excellent material for exhaust systems and heat shields, where it must endure constant high-temperature stress without degrading or losing performance.

- Compressor Blades and Casings: Aerospace engines rely on high-performance compressor blades that compress air before it reaches the combustion chamber. GH2901’s ability to resist both thermal fatigue and mechanical stress makes it an ideal material for compressor blades and casings, which operate at high temperatures and speeds.

- Gas Turbines for Power Generation: GH2901 is commonly used in gas turbines within power generation plants. These turbines operate at high pressures and temperatures, and the alloy’s high creep resistance, combined with its ability to perform at temperatures exceeding 1000°C (1830°F), ensures the durability and longevity of turbine blades, vanes, and other critical components.

- Steam Turbines: In steam turbines, the combination of high temperatures and high pressure can severely degrade materials over time. GH2901’s excellent strength retention at elevated temperatures and its resistance to oxidation make it a reliable material for steam turbine components, ensuring stable operation and reducing maintenance needs.

- Oil & Gas Exploration: In the oil and gas industry, equipment such as drilling rigs, pumps, and compressors must withstand high pressure and corrosive environments. GH2901’s resistance to corrosion and high pressure makes it a suitable material for parts used in deep-water drilling and other high-pressure applications, ensuring a longer service life and improved efficiency.

- High-Temperature Strength: GH2901 is capable of maintaining its strength and structural integrity at temperatures exceeding 1000°C (1830°F), making it suitable for the most demanding applications, such as turbine blades and aerospace engine components. Its high-temperature strength ensures that parts continue to perform optimally under extreme thermal conditions.

- Creep Resistance: Creep is a material's tendency to deform permanently under constant stress at elevated temperatures. GH2901 exhibits excellent creep resistance, which is crucial in components like turbine blades, where long-term exposure to high pressure and temperature could otherwise lead to deformation. This property contributes significantly to the longevity of critical aerospace and power generation components.

- Oxidation and Corrosion Resistance: At high temperatures, oxidation is a significant concern, especially when components are exposed to hot gases or steam. GH2901’s resistance to oxidation ensures that turbine blades, exhaust systems, and other critical components maintain their strength and reliability over extended periods of exposure to high-temperature, high-pressure environments. Furthermore, its corrosion resistance ensures that it remains durable in challenging operating conditions such as marine environments or high-sulfur gases.

- Thermal Fatigue Resistance: In applications where parts undergo frequent heating and cooling cycles, thermal fatigue can cause cracks and material degradation. GH2901’s resistance to thermal fatigue ensures that components like turbine blades and gas nozzles can withstand repeated thermal cycling without losing performance, contributing to the overall reliability and lifespan of engines and turbines.

- High Strength-to-Weight Ratio: In aerospace applications, minimizing weight is critical for improving fuel efficiency and overall performance. GH2901 provides a high strength-to-weight ratio, ensuring that components remain strong enough to handle mechanical stresses while also being lightweight enough to improve efficiency and reduce energy consumption.

- Enhanced Performance and Efficiency: The high-temperature strength and oxidation resistance of GH2901 allow components to operate at higher temperatures and pressures, which leads to more efficient power generation and improved fuel efficiency in aerospace engines. Customers benefit from improved operational performance, increased energy output, and reduced fuel consumption.

- Extended Durability and Reliability: One of the primary customer concerns in high-pressure and aerospace applications is the longevity of components. GH2901’s resistance to creep, thermal fatigue, and oxidation ensures that critical parts like turbine blades, compressor blades, and exhaust systems last longer, reducing the frequency of repairs and replacements. This translates to fewer maintenance disruptions, lower operational costs, and greater system reliability.

- Cost-Effectiveness: Although GH2901 may have a higher upfront cost compared to other alloys, its superior durability and performance over time result in lower overall lifecycle costs. Reduced maintenance requirements, less frequent part replacements, and greater operational efficiency make GH2901 a cost-effective material in the long run.

- Improved Safety: Safety is a critical factor in both aerospace and high-pressure industries. GH2901’s high resistance to thermal degradation, creep, and oxidation ensures that critical components retain their strength and performance under extreme conditions, reducing the risk of catastrophic failure. This makes GH2901 an ideal material for enhancing the safety and reliability of systems in these high-stakes industries.

- Customization for Specific Needs: GH2901 can be tailored to meet the specific requirements of different applications. Whether used in turbine blades, exhaust systems, or other critical components, GH2901 offers the versatility to meet the demands of both aerospace and high-pressure industries, making it a preferred material for custom-engineered solutions.

In industries where performance, reliability, and durability are paramount, the materials used in critical components must meet rigorous standards. GH2901, a high-performance nickel-based superalloy, has been specifically developed to withstand the most demanding environments, including aerospace and high-pressure applications. Known for its exceptional strength, resistance to oxidation, and ability to perform under extreme conditions, GH2901 is an ideal choice for components that must operate under high temperatures, pressures, and mechanical stresses.

Applications of GH2901 in Aerospace and High-Pressure Environments

GH2901’s outstanding material properties make it a go-to alloy for applications that involve extreme conditions. The alloy excels in situations where both high mechanical strength and resistance to thermal degradation are crucial. Some of its primary applications include:

Aerospace Applications

Aerospace components must endure a variety of extreme conditions, including high-speed flight, temperature fluctuations, and mechanical stresses. GH2901 is utilized extensively in both commercial and military aerospace sectors:

High-Pressure Applications

Beyond aerospace, GH2901 is also widely used in various high-pressure industrial environments, where both temperature and pressure reach extreme levels:

Key Properties of GH2901

The superior performance of GH2901 can be attributed to its combination of physical, mechanical, and chemical properties. Some of the key features that make it ideal for aerospace and high-pressure applications include:

Meeting Customer Needs in Aerospace and High-Pressure Industries

As industries evolve and technology advances, the need for materials that can meet the growing demands of high-performance applications becomes even more important. GH2901 addresses several customer needs in both the aerospace and high-pressure industries:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.