Pláitse Hastelloy B-2 – Daltaí Uaschúir le haghaidh Ngalair Corrach

Tá príosúnacht chun cúil na ndéantóirí againn agus cóntae speisialta do chomhorduithe móra. Cúigeofar ár n-ionsaí go tapaidh, cead is cead, chun fothrabhsáil dílis a shníomh don phríomhphobal oiliúna i gcás gur gá ionad beag nó mór.

- Aireamh

- Speisifeicáid

- Feidhmchláir

- Ceisteanna Coitianta

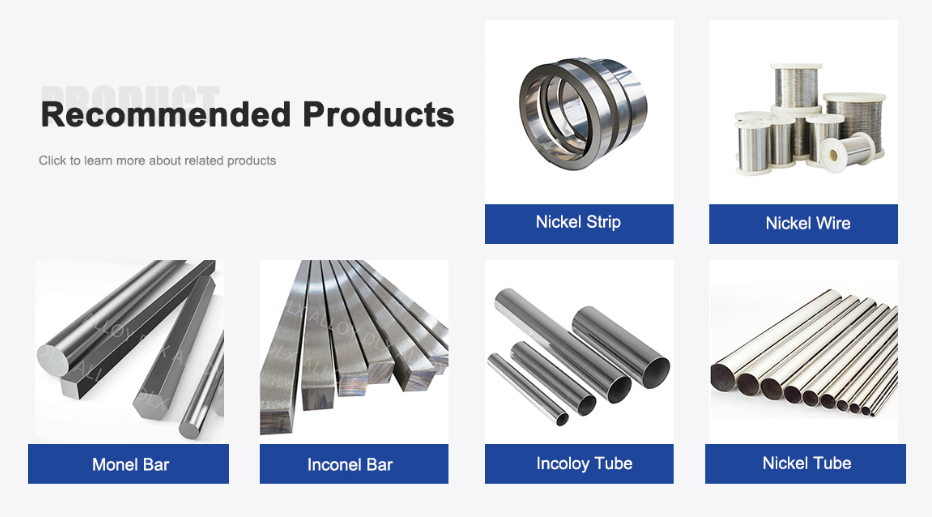

- Táirgí Molta

-

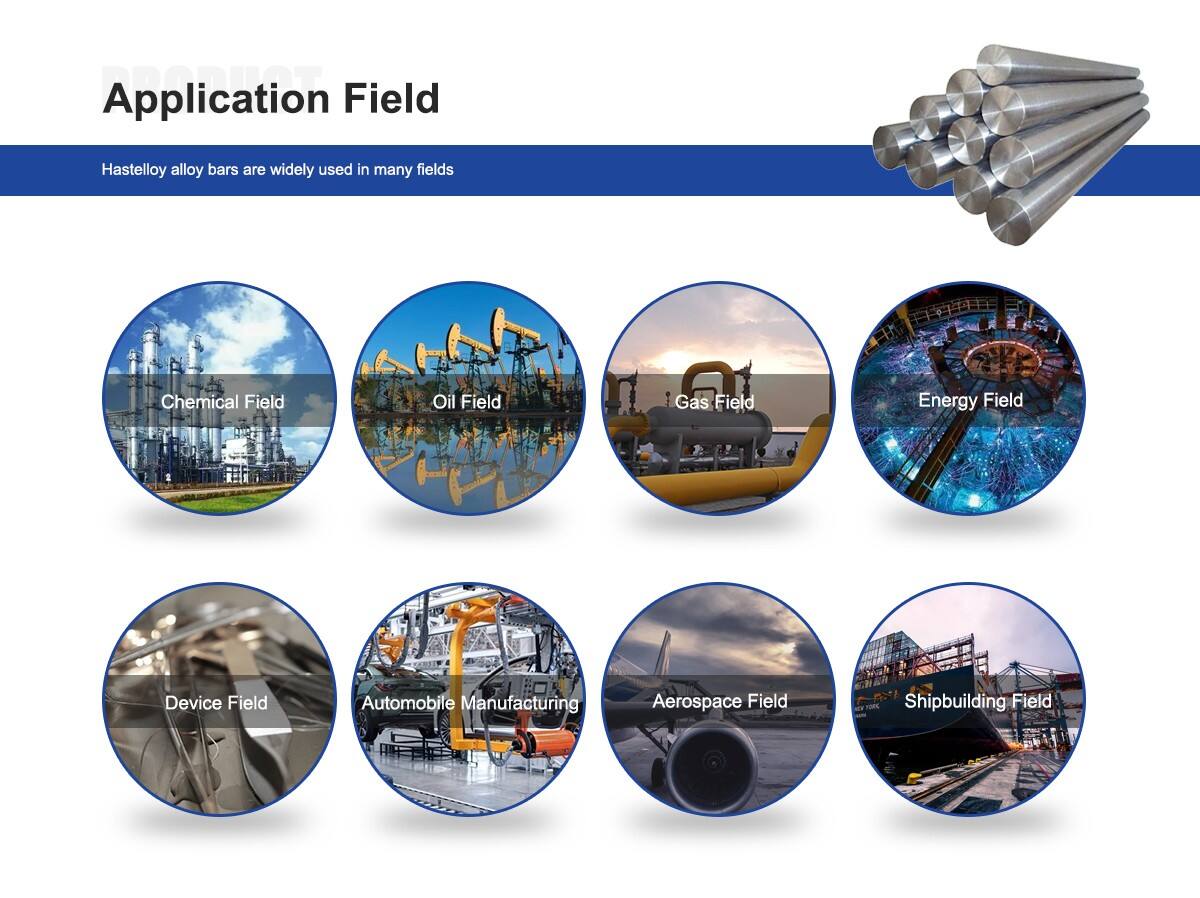

Troidmheas Eiceáidíoch: Inaighneach don chéad dul síos le haghaidh aig bhróga cloiche agus bealaí eile cruthaithe.

-

Neamhspréacht Mecánach Uathuile: Cinntíonn go bhfuil a n-iomlán in iúl san fhostóigeacha agus sa t-thimpeallacht uas-temperatúr.

-

Foghlamadh Maith: Is féidir é a fhógairt go héasca agus a chruthú gan carbaid phríomha a léiriú.

-

Stailéad Teormaíoch Uasal: Comhshuite don úsáid atá ag teastáil tuarascáil consain ar theocht uas-temperatúr.

-

Bheithiúchán Próiseálaíochta: Úsáidear sna heata exchangers, na réictithe, agus na boird sprioc mar a dtugtar dóibh i gcásanna próiseálaíocha tábhachtacha.

-

Saothraí Pharmachaeacha agus Biotéicneolaíochta: Rítháite don t-equipment a thabharfaidh faoi shubstaintí reacdaoiseacha go hiomlán san eanghnai.

-

Giníocht Fuaime agus Seictear Fuinnimh: Curtha i bhfeidhm i scagaire a n-úsáidtear maireachtáil a mbeidh ábhar ann a dtagann tríd an-airde teoraim agus troidmheas.

-

Saothraí Pulp agus Scáth: Úsáidear sna hábhair próiseálaíocha a gcuiretar i gcásanna a bhfuil siad foirmeacha agus caisteach.

-

Innealtóireacht Speisialta agus Mara: Ideal don úsáid i gcomhponaintí a tharlaoidh go soiléir i gcásanna mara agus deimhnithe ríomhaireach.

-

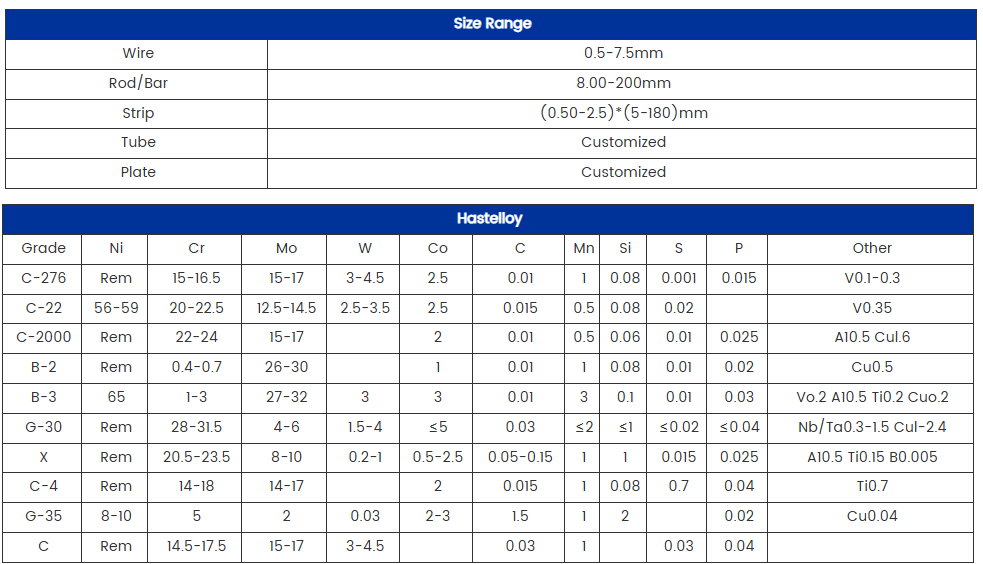

UNS Uimhir: N10665

-

Staidéar ASTM: ASTM B333 (Pléas, Scileanna agus Sraitheanna)

-

EN/DIN Comhchéim: 2.4617

-

Sult agus Allaimh: Déantar an allaimh trí lúibínigh fhuascailte (VIM) nó trí phróiseáil inar (EAF).

-

Rolleáil agus Formáil: Téchníocail rolleála teoranta agus fuar feabhsóid na n-earraí chuig mírtheálanna príosúnacha.

-

Gnó Théarmha (Anailéad): Meastar éifeachtacht agus comhlíonadh corrscairt.

-

Iarratas Faoi Chroí: Gluaiseann pickling agus passivation scáthán chóir agus forbairt corrscairt.

-

Glacadh ar Ghníomh: Tástáil chrua, lena n-áiríte anailís chóras deimhnithe agus meastachán meicniúla, chun cinntiú gur imlígthe le riachtanais sna ngréasáin.

-

Fadhbéimíochtaí agus Mírtheálanna Éagsúla: Tá pléas ar fáil i ngéarchuid éagsúla do chúrsaí bhrathaireachta éagsúla.

-

Roghanna Fiontra Brath: Fiontra mill, polaiteach nó coibhthe chun fhostaíocht níos faoi láthair a chur ar fáil.

-

Cumas Deargaithe agus Cumas Feabhsuithe: Glacadh le comhionannacht le teicniocltí éagsúla fabhrachála.

-

Cinntiú le Staidéar Rialacha: Ag baint le certifiúcháin ASTM, ASME agus eile ar fud an domhain.

Is féidir le Hastelloy B-2, alaún nícil-molibhánach a bhfuil aithne air mar thoradh éagsúla ar shuíomhanna laghdaithe cosúil le hác chlóraid, oibriú mar phláitse agus tabhairt comhthéacs iontach i gcás timpeallaithe corrógacha lárnach, ag déanamh di scagaire thar a bheith deacair ag dul trí é, agus tá sí rogha idéala don ghnéitheacht a bhaineann le cúram is cumas cheimiceach.

Comhoibriú Ábhar agus Airíonna

Tá Hastelloy B-2 gníomhach go mór as nícil agus molibhánach, a chuireann na hathruithe bunúsacha seo ar fáil:

Iarratais le Pláitse Hastelloy B-2

Grianghraf ar fáil de bharr an tuarascáil ardchaighdeánach ciorcalach, Pláitse Hastelloy B-2 úsáidtear go hiomlán sna n-iompair seo:

Gradaí agus Staidéar

Tá plátaí Hastelloy B-2 ag comhionannacht le n-iomlán daingnithe idirnáisiúnta chun ceart agus feabhsuithe a shuíomh:

Próiseas Déantúsaíochta

Tá an toradh ionannach ar phlataí Hastelloy B-2 ag leanúint próiseas stricte chun ucht agus níos míneálaí a choinneáil:

Riachtanais Úsáideora agus Aigneálacha

Tá rialacha speisialta ag tuiscean a úsáid le plátaí Hastelloy B-2 chun na n-iarrachtaí oibriúcháin a fheabhsú. I measc na gcóras coitianta:

Conclúid

Tugann na plátaí Hastelloy B-2 díbirt gan choinne ag comhpháirt le n-áiteanna íseal corcair, ag cinntiú go bhfuil siad tábhachtach do thuiscean a bheidh ag teastáil ó mhatérialí fiorghoirt agus ardchaighdeán. Is roinnt den chuid is fearr acu i gcásanna meicniocacha, stabilité mar thoradh théarmna agus roghaíochtaí coitianta, a dhéanann orthu rogha iontach don tsaothar tionsclaíoch íofhar.

Ceisteanna Coitianta:

Cén faoi is féidir leat an t-ordú a chur?

Déanann sé as ucht méid na n-orduithe, 10-30 lá donn ordú beaga. Donn ordú móra, bíonn 60 lá ag teastáil.

An gceapann sibh ar phróiseas OEM/ODM?

Tá! Ceapann sibh ar phróiseas OEM/ODM. Is féidir leat samplaí nó dréachtaí a sheoladh dúinn.

Conas a rialtaíonn sibh an gairid thar a bheith agus an bhfuil na ngníomhartha bitheolaíochta de réir na gcásanna cearta?

Le hiomlán tim pearsanta gairide, plánáil gairide éagsúla, cur i bhfeidhm shtrict agus fócas ar fhrámaí nuálaithe, tabharfaidh muid certiúlacht scagadh gairide, lena n-áirítear tuairisc anailíse bitheolaíochta.

An féidir le do chuideachta sonraí teicniúla détaílte agus dréachtaí a sholáthar?

Tá, tá. Déan cinntiúr linn cad na pródait agus na n-iarratais atá ag teastáil uait, agus seolfaimid sonraí teicniúla détaílte agus dréachtaí chun do mheasúnú agus do chomhdhéanamh.

Conas a dhéanann sibh comhairleacht roimh agus tar éis an siopadóireachta?

Tá foireann gairmiúil againn a mbeidh ag obair ar aon leith chun cosaint na n-iarmhíreanna do phróduct, agus má tá aon cheist ort, is féidir leis an ceist sin a fhreagairt duit!

An bhfuil cáiliúint agam ar pháirc na ndéanta sula gcuirfidh mé ordú i bhfeidhm?

Is maith linn, tú slán le fáil isteach chuig ár pháirc. Táimid sásta an deis a bheith againn chun a chéile a lorg.

Cá bhfuil do bheith in ionad pleanála?

Tógaimid ár n-athruithe i gCorcach Suain, na hÉisean agus cuirimid iad ar bord ón Éis go dtí do chóras chomh luath agus is féidir, atá de ghnáth níos déanaí ar shon na n-iarmhíreanna agus na n-uisce.

An bhféadfá samplaí a sheoladh?

Sea, is féidir linn.