FeNi50 Alloy Bars for High-Strength Applications in Precision Instruments

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

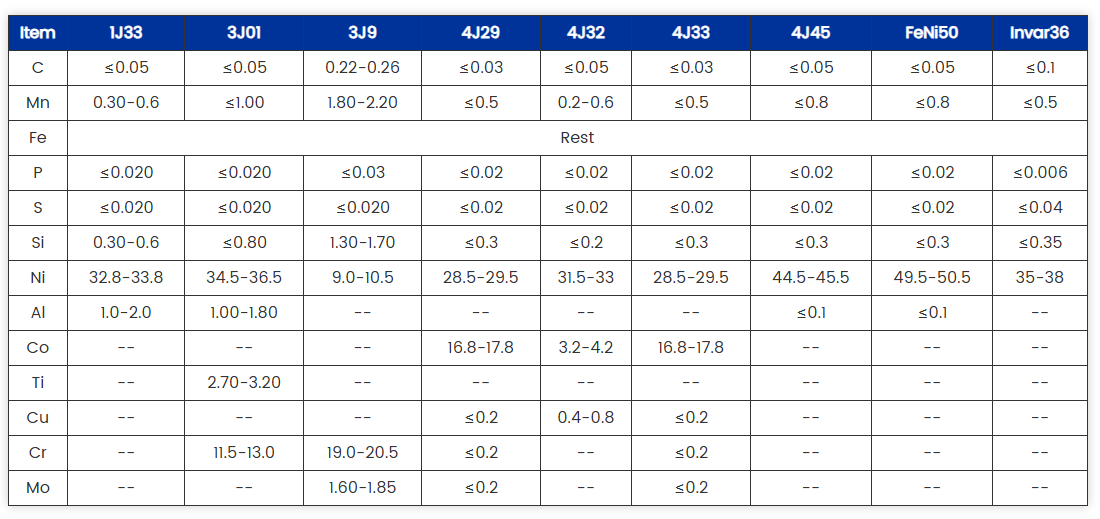

- Specification

- About Us

- FAQs

- Recommended Products

-

Precision Instruments

One of the primary applications of FeNi50 alloy bars is in precision instruments, where high strength and dimensional stability are crucial. In instruments such as optical devices, micrometers, calipers, and measuring tools, FeNi50 bars are used to manufacture critical components that require extreme accuracy. The alloy’s low thermal expansion ensures that these devices maintain their precision even when exposed to temperature fluctuations. By offering high strength and tensile strength, FeNi50 ensures that components remain intact and function properly under stress, extending the life of these essential tools. -

Aerospace and Defense Equipment

The aerospace and defense industries require materials that can withstand extreme conditions while maintaining their integrity. FeNi50 alloy bars are widely used in these sectors, especially for high-strength components such as mounting brackets, fasteners, and structural elements in aerospace instruments. FeNi50’s dimensional stability under changing temperatures makes it ideal for use in sensitive equipment such as radar systems, navigation devices, and communication equipment. This alloy ensures that aerospace and defense systems function optimally, even in extreme environments, where accuracy and reliability are non-negotiable. -

Precision Electronic Components

FeNi50 alloy bars are also used in the production of precision electronic components that require high strength and dimensional stability. In telecommunication devices, semiconductors, and circuit boards, FeNi50 alloy offers the mechanical properties necessary to support small, delicate components without compromising performance. The alloy's corrosion resistance ensures long-lasting durability in devices exposed to environmental stressors, making it a preferred choice for applications in consumer electronics and medical devices where reliability is critical. -

Measurement and Calibration Equipment

Measurement systems used in industrial settings, research laboratories, and scientific applications require materials with consistent and precise characteristics. FeNi50 alloy bars are often employed in the construction of calibration tools, measuring rods, and precision gauges. These components are essential in ensuring the accuracy of measurements and the precision of mechanical systems. FeNi50’s high-strength properties ensure that these tools perform under demanding conditions, maintaining their dimensional accuracy over time, even with repeated use. -

Optical Instruments

In the optical and photonic industries, FeNi50 alloy bars are used to make components such as lenses, mirrors, and optical mounts. The alloy’s thermal expansion properties make it ideal for ensuring that optical instruments maintain their alignment and accuracy in varying environmental conditions. FeNi50 is also used in telescope mounts, laser alignment systems, and microscopes, where precise adjustments are critical for the proper functioning of high-precision optical systems. -

High Strength and Durability

Customers using FeNi50 alloy bars demand high strength to ensure that components can withstand physical stresses and mechanical loading without failure. In precision instruments, where small components often undergo continuous operation, the high tensile strength of FeNi50 ensures that these devices remain functional and reliable for long periods. This is especially important in sectors like aerospace, military, and scientific instrumentation, where failure or deformation of components can lead to inaccuracies and system failures. -

Dimensional Stability

Dimensional stability is a key requirement for users of FeNi50 alloy, particularly in applications such as precision measurement tools and optical instruments. The low coefficient of thermal expansion of FeNi50 ensures that components do not expand or contract with temperature changes, maintaining their shape and accuracy. In environments where temperature fluctuations are common, this stability guarantees that equipment maintains high accuracy throughout its lifecycle, which is a critical factor for industries that rely on precision measurements. -

Corrosion Resistance

Many industries, especially those in electronics, aerospace, and military, require materials with high corrosion resistance to prevent degradation over time. FeNi50 alloy bars offer resilience against rust, oxidation, and other forms of corrosion, ensuring that critical components last longer and perform reliably even in harsh environments. Customers expect the alloy to provide consistent performance in both humid and high-temperature environments, reducing the frequency of maintenance or replacement of components. -

Precision and Accuracy

Users of FeNi50 alloy are often involved in industries where precision and accuracy are paramount. Whether it's for measuring instruments, calibration systems, or aerospace sensors, the demand for materials that do not distort or warp over time is high. FeNi50 is expected to deliver exceptional dimensional stability, ensuring that components retain their exact measurements and alignments, even in demanding and changing conditions. -

Long-Term Reliability

FeNi50 alloy bars must provide long-term reliability to meet the needs of industries that require continuous operation without failure. In aerospace, military, and medical equipment, components must last for extended periods, often in challenging environments. FeNi50 meets these needs with its high-strength, corrosion-resistant, and dimensionally stable properties, ensuring the durability and reliability of critical instruments.

FeNi50, a nickel-iron alloy composed of approximately 50% nickel and 50% iron, is renowned for its excellent mechanical properties and thermal stability. This alloy is particularly valued for its high strength, dimensional stability, and resilience to external stresses, making it a top choice for precision instruments that require accuracy, durability, and reliable performance over time. The combination of its balanced composition and exceptional physical characteristics ensures that FeNi50 alloy is an ideal material for industries that demand precision, reliability, and resilience in their instruments.

With a low coefficient of thermal expansion (CTE), FeNi50 alloy maintains its dimensional stability even under varying temperature conditions. This characteristic, coupled with its high strength and corrosion resistance, makes it an essential material in applications that require both precision and long-term performance.

Applications of FeNi50 Alloy Bars

User Demands and Requirements

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

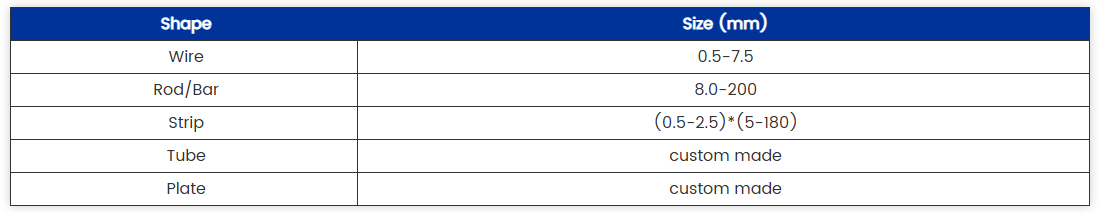

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.