نوار آلیاژ نیکل Ni200 ضخامت 0.2mm | صنایع الکتریکی و باتری | پیشنهاد قیمت gros

ما قیمت مستقیم کارخانه و تخفیف ویژه برای سفارشات انبوه را ارائه میدهیم. آیا نیاز به مقدار کوچک یا بزرگ دارید، محصولات ما به سرعت ارسال میشوند تا تأمین قابل اتکا برای پروژههای صنعتی در سراسر جهان را تضمین کنند.

- بررسی اجمالی

- مشخصات

- کاربردها

- سوالات متداول

- محصولات پیشنهادی

مقدمهای بر نوار آلیاژ نیکل Ni200

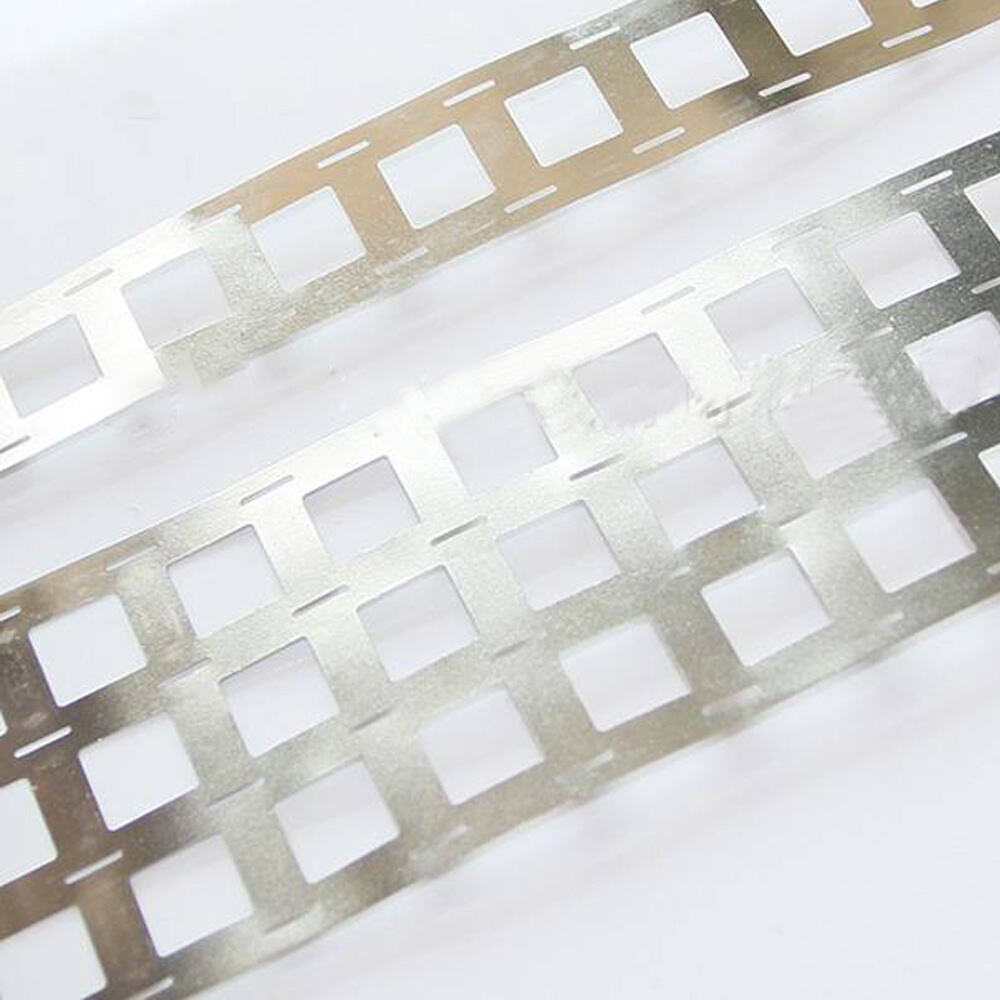

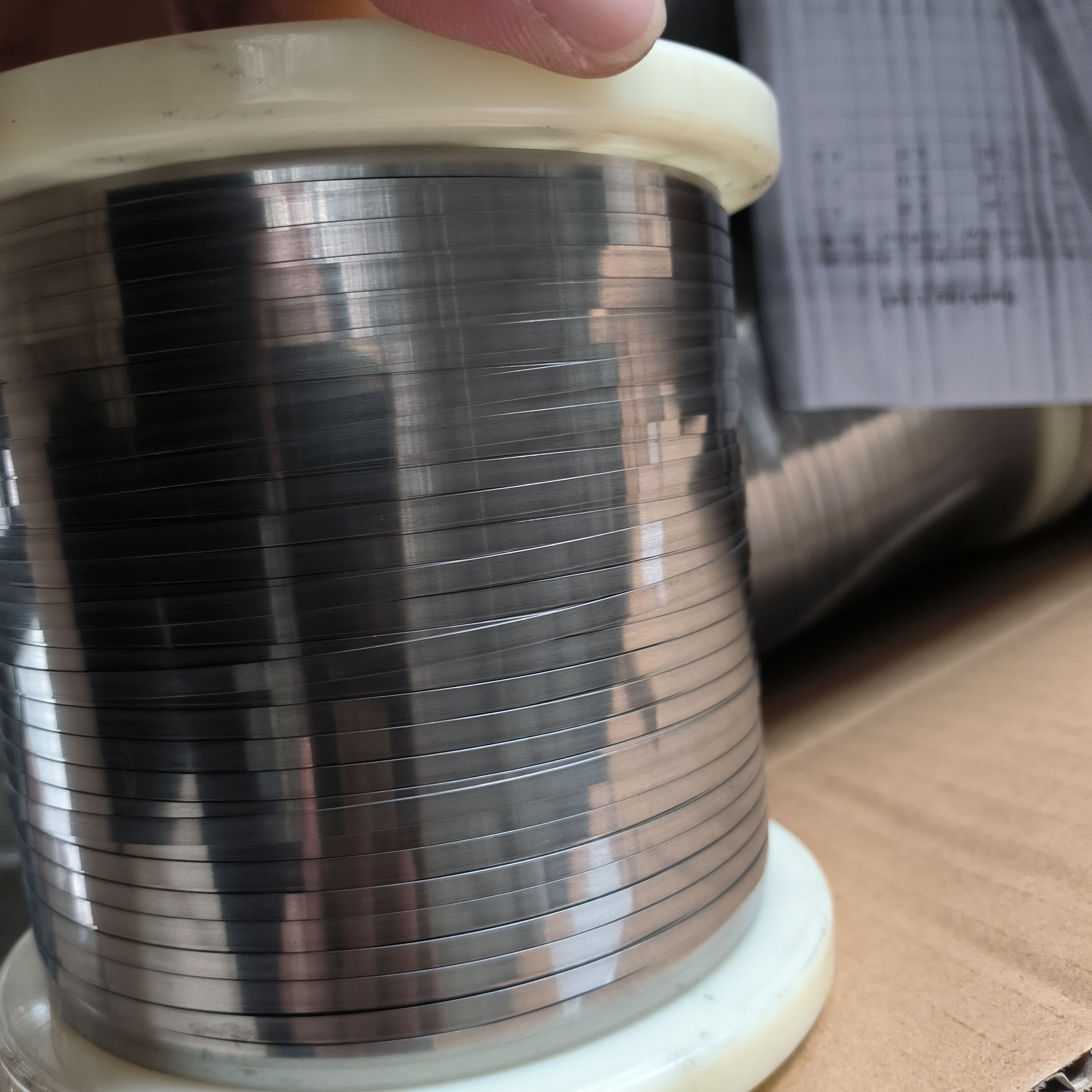

نوار آلیاژ نیکل Ni200 یک ماده نیکل با خالصی بالا (≥99.6% نیکل) است که به دلیل رسانایی الکتریکی عالی، مقاومت ضد فرسودگی و پایداری حرارتی شناخته شده است. با ضخامت 0.2 میلیمتر، این نوار در سازههای برقی، وصلههای باتری، پردازش شیمیایی و کاربردهای فضایی به کار میرود.

به عنوان تأمینکننده مستقیم کارخانه، ما اندازههای سفارشی، سفارشهای انبوه و پردازش OEM را ارائه میدهیم که راهحلهای کارآمد و با کیفیت بالا برای کاربردهای صنعتی تضمین میکند.

ویژگیهای کلیدی نوار آلیاژ نیکل Ni200

✔ خالصی نیکل بالا (≥99.6%) – اطمینان از رسانایی الکتریکی و حرارتی برجسته.

✔ مقاومت عالی علیه فرسودگی و اکسیداسیون – مناسب برای محیطهای سخت و معرض مواد شیمیایی.

✔ قوت مکانیکی و تراکیب بالا – اجازه میدهد پردازش آسان و تولید دقیق انجام شود.

✔ قابلیت جوشابی و لُتمانی خوب – مناسب برای کاربردهای الکترونیکی و باتری.

✔ قیمت های تولیدی با ارسال جهانی – راهکارهای اقتصادی برای استفاده صنعتی.

کاربردهای نوار آلیاژ نیکل Ni200 (ضخامت 0.2 میلیمتر)

1. صنعت برق و مولفههای هدایت کننده

استفاده در وصلههای برق، سیمهای حمل جریان و نوارهای هدایت کننده.

تضمین جریان برق پایدار و کارآمد در دستگاههای الکترونیکی.

Fone فراهم آوردن مقاومت الکتریکی پایین برای کاربردهای با عملکرد بالا.

2. تولید باتری و سیستمهای ذخیره انرژی

ضروری برای وصلههای باتری، ترمینالها و تابهای باتری لیتیوم-یون.

افزایش کارایی باتری و عملکرد بلندمدت آن.

پشتیبانی از سیستمهای ذخیره انرژی ش充 الشارژپذیر و با ظرفیت بالا.

۳. فضایی و کاربردهای دمای بالا

در قطعات فضایی، مبدل گرماها و سیستمهای توربین استفاده میشود.

مقاومت در برابر دمای عالی و محیطهای شیمیایی سخت دارد.

ویژگیهای سازنداری و هدایت کننده قابل اعتمادی را ارائه میدهد.

4. فرآورش شیمیایی و تجهیزات مقاوم به خوردگی

برای خزانهای شیمیایی، سیستمهای لولهکشی و قطعات فیلتراسیون مناسب است.

مقاومت در برابر اسیدها، قلیاها و مواد شیمیایی صنعتی عجولانه دارد.

در صنایع دریایی، دارویی و پردازش غذا استفاده میشود.

مشخصات فنی نوار آلیاژ نیکل Ni200

جزئیات مشخصات

مواد نیکل خالص Ni200 (≥99.6%)

ضخامت 0.2mm

عرض قابل سفارش

متقابلاً با استاندارد ASTM B162, GB/T 2054-2005 مطابقت دارد

نقطه ذوب 1435°C (2615°F)

مقاومت کششی ≥380 MPa

مقاومت الکتریکی ≤0.099 Ω·mm²/m

چرا نوار آلیاژ نیکل Ni200 ما را انتخاب کنید؟

✔ تأمین مستقیم از کارخانه – قیمت رقابتی و کیفیت قابل اعتماد

✔ پردازش سفارشی در دسترس – طراحی شده برای نیازهای صنعتی شما

✔ ارسال سریع جهانی – سفارشات بزرگ و پشتیبانی OEM

✔ ضمانت خلوص بالا و عملکرد عالی

سوالات متداول:

زمان تحویل چقدر طول میکشه؟

بستگی به مقدار سفارش دارد، برای سفارشهای کوچک 10 تا 30 روز زمان لازم است. برای سفارشهای بزرگ، 60 روز طول میکشد.

آیا تولید OEM/ODM پذیرفته میشود؟

بله! ما تولید OEM/ODM را پذیرفته میشود. میتوانید نمونهها یا طرحهای خود را به ما ارسال کنید.

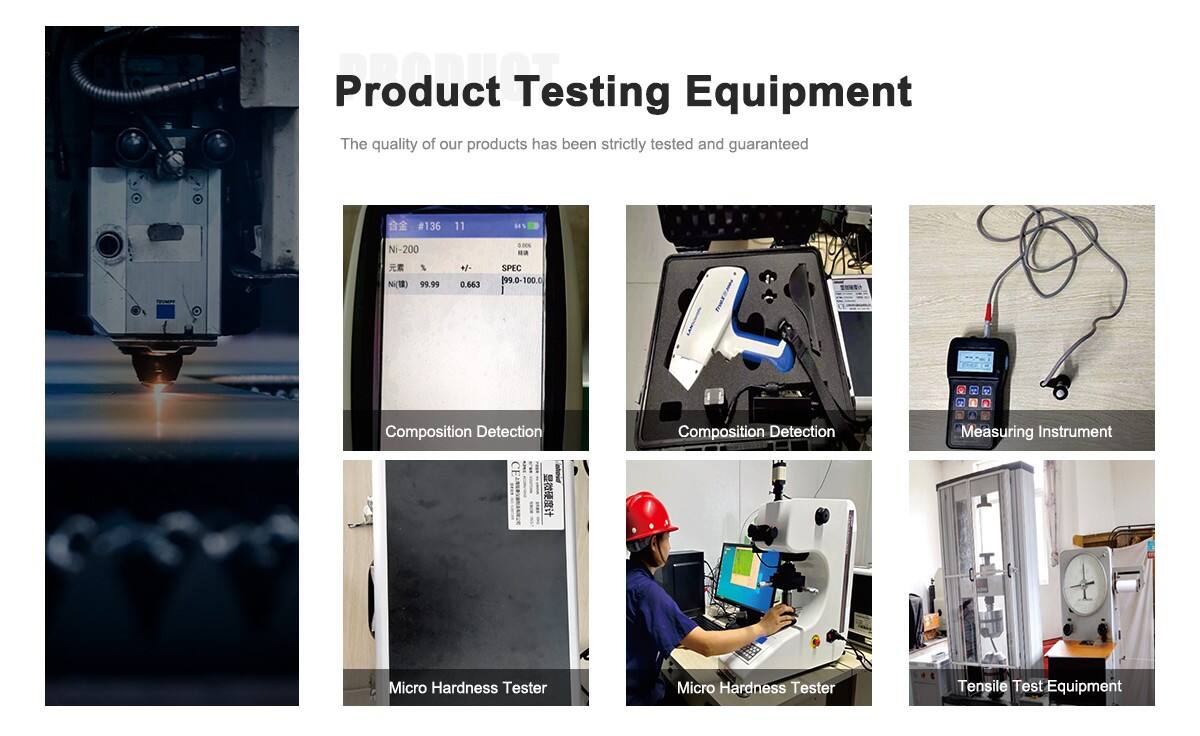

چگونه کیفیت محصولات خود را کنترل میکنید؟ آیا ویژگیهای شیمیایی محصولات با استانداردهای کیفیت همخوانی دارند؟

با تیم کیفیت حرفهای، برنامهریزی پیشرفته کیفیت محصول، اجرای صریح و بهبود مستمر، ما گواهینامه بررسی کیفیت محصول صادر خواهیم کرد، شامل گزارش تجزیه و تحلیل شیمیایی.

آیا شرکت شما میتواند اطلاعات فنی دقیق و طرحها را ارائه دهد؟

بله، میتوانید. لطفاً محصولات و کاربردهایی که نیاز دارید را به ما بگویید و ما اطلاعات فنی دقیق و طرحهای مربوطه را برای ارزیابی و تأیید شما ارسال خواهیم کرد.

چگونه خدمات پیش از فروش و پس از فروش را مدیریت میکنید؟

ما یک تیم حرفهای فروش داریم که به صورت یک به یک برای حفاظت از نیازهای محصول شما کار میکنند، و اگر هرگونه سوالی دارید، او میتواند آنها را برای شما پاسخ دهد!

آیا میتوانم قبل از ثبت سفارش به کارخانه شما بروم؟

بله، شما خوشحالانه میتوانید به کارخانه ما بیایید. ما از فرصت آشنایی با شما خوشبینی میکنیم.

کارخانه تولید شما کجاست؟

ما محصولات را در استان جیانگسو، چین تولید میکنیم و هر چند زودتر آنها را از چین به کشور شما ارسال میکنیم، که معمولاً بستگی به نیازهای محصولی شما و مقدار سفارش دارد.

آیا میتوانید نمونه ارسال کنید؟

بله، ما میتوانیم.