سیم لاستیک Hastelloy C-276 (ERNiCrMo-4) – بهترین تأمینکننده، قیمت کارخانه عالی

بیشتر: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6. ما قیمت مستقیم کارخانه را با تخفیف ویژه برای سفارشات انبوه ارائه میدهیم. آیا نیاز به مقدار کوچک یا بزرگ دارید؟ Draad چسبانی ERNiCrMo-4 ما برای ارسال فوری در دسترس است و تأمین قابل اعتماد برای پروژههای صنعتی در سراسر جهان را تضمین میکند.

- خلاصه

- سوالات متداول

- محصولات پیشنهادی

مقدمهای بر Draad چسبانی Hastelloy C-276 (ERNiCrMo-4)

سیم لاستهآلی C-276 (ERNiCrMo-4) یک آلیاژ مبتنی بر نیکل با عملکرد بالا است که برای کاربردهای درون محیطهای شدید طراحی شده است. این آلیاژ به دلیل مقاومت بینظیر ضد خوردگی، قوی بودن در دماهای بالا و قابلیت جوشکاری عالی، در صنایع پردازش شیمیایی، تولید انرژی، نفت و گاز، دریایی و فضایی گسترده استفاده میشود.

به عنوان یک تأمینکننده برتر، ما سیم لاستهآلی C-276 با کیفیت بالا را به بهترین قیمت کارخانهای ارائه میدهیم. آیا نیاز به سفارشهای کوچک یا حجم زیاد دارید؟ ما راهحلهای سفارشی، تحویل سریع و قیمت gros به منظور برآورده کردن نیازهای صنعتی شما ارائه میدهیم.

بازبینی مواد: ویژگیهای سیم لاستهآلی C-276 (ERNiCrMo-4)

لاستهآلی C-276، که همچنین به عنوان ERNiCrMo-4 شناخته میشود، یک آلیاژ نیکل-کروم-مولیبد است که به طور خاص برای محیطهای بسیار خوردگیزا و شرایط شدید طراحی شده است. ویژگیهای کلیدی شامل:

✔ مقاومت بینظیر در برابر خوردگی – حفاظت برتری علیه خوردگی نقطهای، خوردگی شکافی و شکست خوردگی ناشی از تنش در محیطهای غنی با کلر و اسیدی فراهم میکند.

✔ قوی بودن در دمای بالا – ساختاری کامل را در دماهای تا 1093°C (2000°F) حفظ میکند.

✔ قابلیت جوشابی عالی – جوشهای تمیز و بدون عیب تولید میکند که انشعاب گرم حداقل است.

✔ مقاومت شیمیایی برتر – به عوامل اکسیدان و کاهنده، از جمله اسیدهای سولفوریک، هیدروکلریک و نیتریک مقاومت میکند.

✔ پایداری بلندمدت – در برابر شرایط صنعتی سخت، فشارهای شدید و نوسانات حرارتی مقاومت میکند.

این ویژگیها سیم جوش Hastelloy C-276 را به یک ماده ضروری برای صنایعی که به جوشهای مقاوم به خوردگی و طول عمر بالا نیاز دارند، تبدیل میکند.

| استاندارد | مشخصات |

|---|---|

| AWS A5.14 | ERNiCrMo-4 |

| شماره UNS | N10276 |

| استاندارد ASTM | ASTM B574, ASTM B575 |

| استاندارد ISO | ISO 18274: NiCr15Mo16Fe6W4 |

کاربردهای سیم لاستهلوا C-276 (ERNiCrMo-4)

سیم لاستهلوا C-276 در صنایعی که مقاومت علیه خوردگی، قوی بودن در دماهای بالا و طولانی بودن عمر استفاده شده، نقش اصلی ایفا میکند.

1. صنعت پردازش شیمیایی

مبدل حرارتها و سیستمهای سازگار – مقاومت علیه اcidoهای قوی و مواد شیمیایی تهاجمی را تضمین میکند.

ظرفهای واکنش و تانکهای فشاری – در برابر محیطهای خوردگیزای و دماهای بالا محافظت میکند.

پمپها و شیرها – یکپارچگی ساختاری را در نیروگاههای پردازش اcidoی حفظ میکند.

2. تولید انرژی و صنعت هستهای

بخارچالها و توربینهای بخار – به تحمل اکسیداسیون و تنش حرارتی بالا کمک میکند.

سیستمهای بازیابی حرارت – خوردگی و زوال مواد را جلوگیری میکند.

Komponentهای رآکتور هستهای – مقاومت علیه تابش و گرما را فراهم میکند.

3. صنعت نفت و گاز

تجهیزات حفاری دریایی و لولهکشیها – علیه شکستگی استرسی سولفید (SSC) و آبسنگیشدگی هیدروژن مقاومت میکند.

تانکهای ذخیرهسازی گاز طبیعی مایع و کریوژنیک – نیروی ساختاری را در شرایط دمای بسیار پایین حفظ میکند.

واحدهای پردازش تصفیه خانه – استحکام را در محیطهایی با محتوای بالای سولفور و اسیدی حفظ میکند.

4. مهندسی فضایی و دریایی

프로그اه جت – برای کاربردهای فضایی با دمای بالا و فشار زیاد طراحی شده است.

ساخت کشتی و سیستمهای آب دریایی – ه烂آوری را در محیطهای دریایی جلوگیری میکند.

5. داروسازی و پردازش غذا

لولهکشی بهداشتی و مبدل حرارت – راهحلهایی ضد ه烂 و بهداشتی فراهم میکند.

تجهیزات استریلیزاسیون پزشکی – مقاومت در برابر عوامل تمیزکننده شدید و دماهای بالا دارد.

چرا باید از سیم لاستهزنی Hastelloy C-276 (ERNiCrMo-4) ما انتخاب کنید؟

✅ تأمینکننده برتر با قیمت مستقیم از کارخانه – نرخ رقابتی برای سفارشات انبوه و عمده.

✅ ماده کیفیت بالا گواهی شده - معیارهای AWS، ASTM و ISO را برآورده میکند.

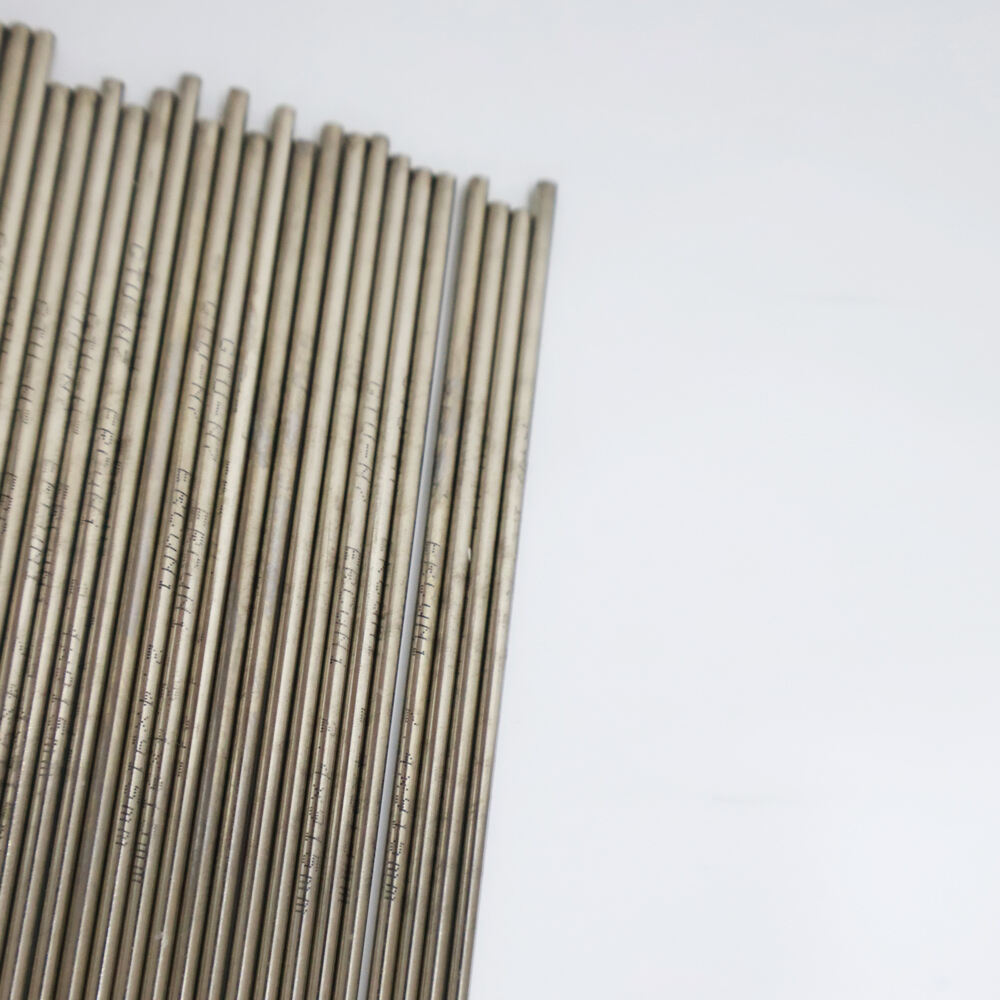

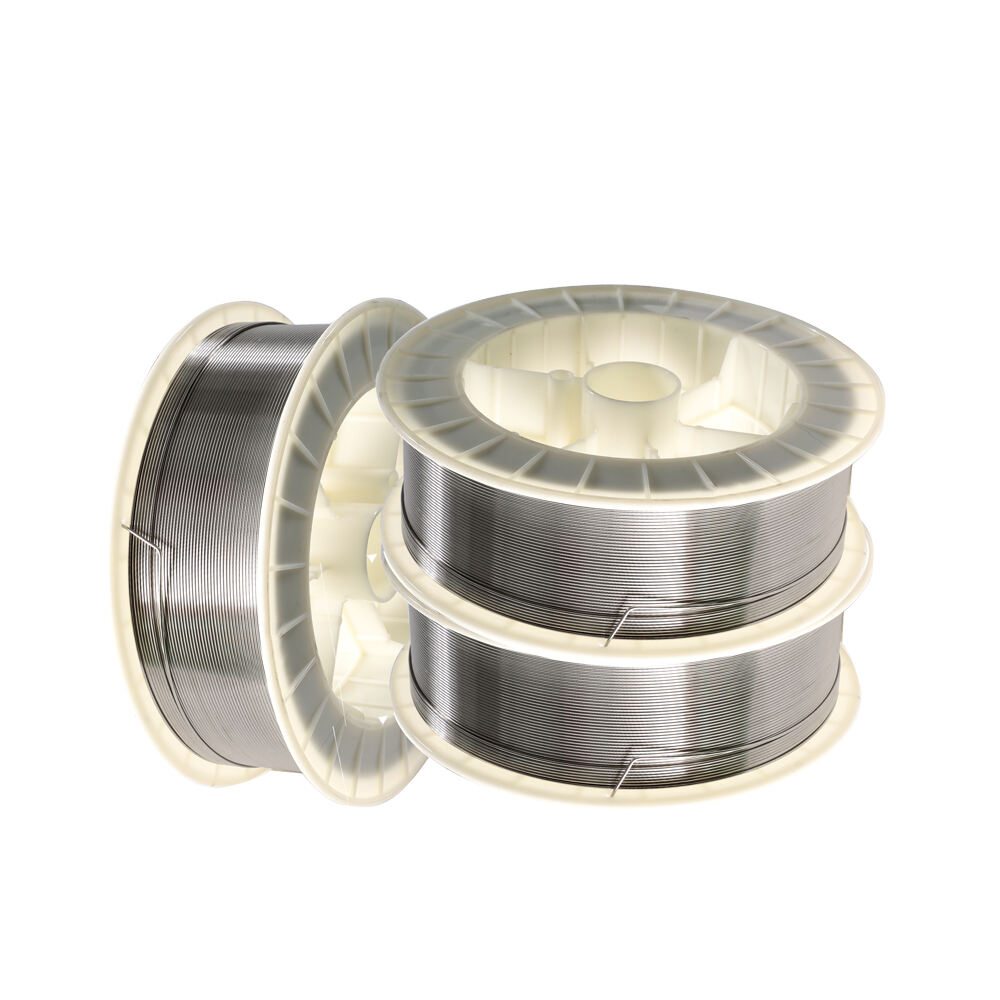

✅ ابعاد و بستهبندی سفارشی – در دسترس به صورت لولههای کشیده، حلقهها و طولهای سفارشی برشداده شده.

✅ ارسال سریع و قابل اتکا در سطح جهانی - تأمین زمانی مناسب برای پروژههای بحرانی.

✅ موجودی قابل اعتماد - همیشه در انبار برای کاربردهای صنعتی بزرگ مقیاس.

زمان تحویل چقدر طول میکشه؟

بستگی به مقدار سفارش دارد، برای سفارشهای کوچک 10 تا 30 روز زمان لازم است. برای سفارشهای بزرگ، 60 روز طول میکشد.

آیا تولید OEM/ODM پذیرفته میشود؟

بله! ما تولید OEM/ODM را پذیرفته میشود. میتوانید نمونهها یا طرحهای خود را به ما ارسال کنید.

چگونه کیفیت محصولات خود را کنترل میکنید؟ آیا ویژگیهای شیمیایی محصولات با استانداردهای کیفیت همخوانی دارند؟

با تیم کیفیت حرفهای، برنامهریزی پیشرفته کیفیت محصول، اجرای سختگیرانه و بهبود مستمر،

گواهی نامه بازرسی کیفیت محصول صادر خواهد شد، شامل گزارش تجزیه شیمیایی.

آیا شرکت شما میتواند اطلاعات فنی دقیق و طرحها را ارائه دهد؟

بله، میتوانید. لطفاً محصولات و کاربردهایی که نیاز دارید را به ما بگویید و ما اطلاعات فنی دقیق و طرحهای مربوطه را برای ارزیابی و تأیید شما ارسال خواهیم کرد.

چگونه خدمات پیش از فروش و پس از فروش را مدیریت میکنید؟

ما یک تیم حرفهای فروش داریم که به صورت یک به یک برای حفاظت از نیازهای محصول شما کار میکنند، و اگر هرگونه سوالی دارید، او میتواند آنها را برای شما پاسخ دهد!

آیا میتوانم قبل از ثبت سفارش به کارخانه شما بروم؟

بله، شما خوشحالانه میتوانید به کارخانه ما بیایید. ما از فرصت آشنایی با شما خوشبینی میکنیم.

کارخانه تولید شما کجاست؟

ما محصولات را در استان جیانگسو، چین تولید میکنیم و هر چند زودتر آنها را از چین به کشور شما ارسال میکنیم، که معمولاً بستگی به نیازهای محصولی شما و مقدار سفارش دارد.

آیا میتوانید نمونه ارسال کنید؟

بله، ما میتوانیم.