Placas de Monel 400 de Grado Industrial - Rendimiento Duradero y Largo

Ofrecemos precios directos de fábrica y descuentos especiales para pedidos por mayor. Ya sea que necesites cantidades pequeñas o grandes, nuestros productos se envían rápidamente para garantizar un suministro confiable para proyectos industriales en todo el mundo.

- Resumen

- Especificación

- Aplicaciones

- Preguntas frecuentes

- Productos Recomendados

- Níquel (Ni): 63.0% mínimo

- Cobre (Cu): 28.0-34.0%

- Hierro (Fe): ≤ 2.5%

- Manganeso (Mn): ≤ 2.0%

- Silicio (Si): ≤ 0.5%

- Carbono (C): ≤ 0.3%

- Azufre (S): ≤ 0.024%

- Resistencia Superior a la Corrosión – Rendimiento excepcional en entornos marinos y químicos, resistiendo agua salada y condiciones ácidas.

- Alta Resistencia y Dureza – Mantiene excelentes propiedades mecánicas en un amplio rango de temperaturas.

- Buen Soldabilidad y Maquinabilidad – Se puede fabricar fácilmente utilizando procesos estándar de soldadura y maquinado.

- Excelente Conductividad Térmica – Capacidad eficiente de transferencia de calor, lo que lo hace ideal para intercambiadores de calor.

- Construcción naval, ejes de hélices y tuberías de agua de mar

- Componentes de submarinos y plataformas de perforación offshore

- Tanques y recipientes resistentes a ácidos y álcalis

- Cambios de calor y evaporadores

- Generadores de vapor y reactores nucleares

- Componentes de calderas expuestos a entornos corrosivos

- Tanques de combustible de aviones y componentes de motores de turbina

- Sistemas de escape en vehículos de alto rendimiento

- Tubos y accesorios para la extracción de gas ácido y petróleo crudo

- Válvulas y componentes de bombas en perforación offshore

- Selección de Material Crudo – Se utiliza el aleación Monel 400 de grado premium.

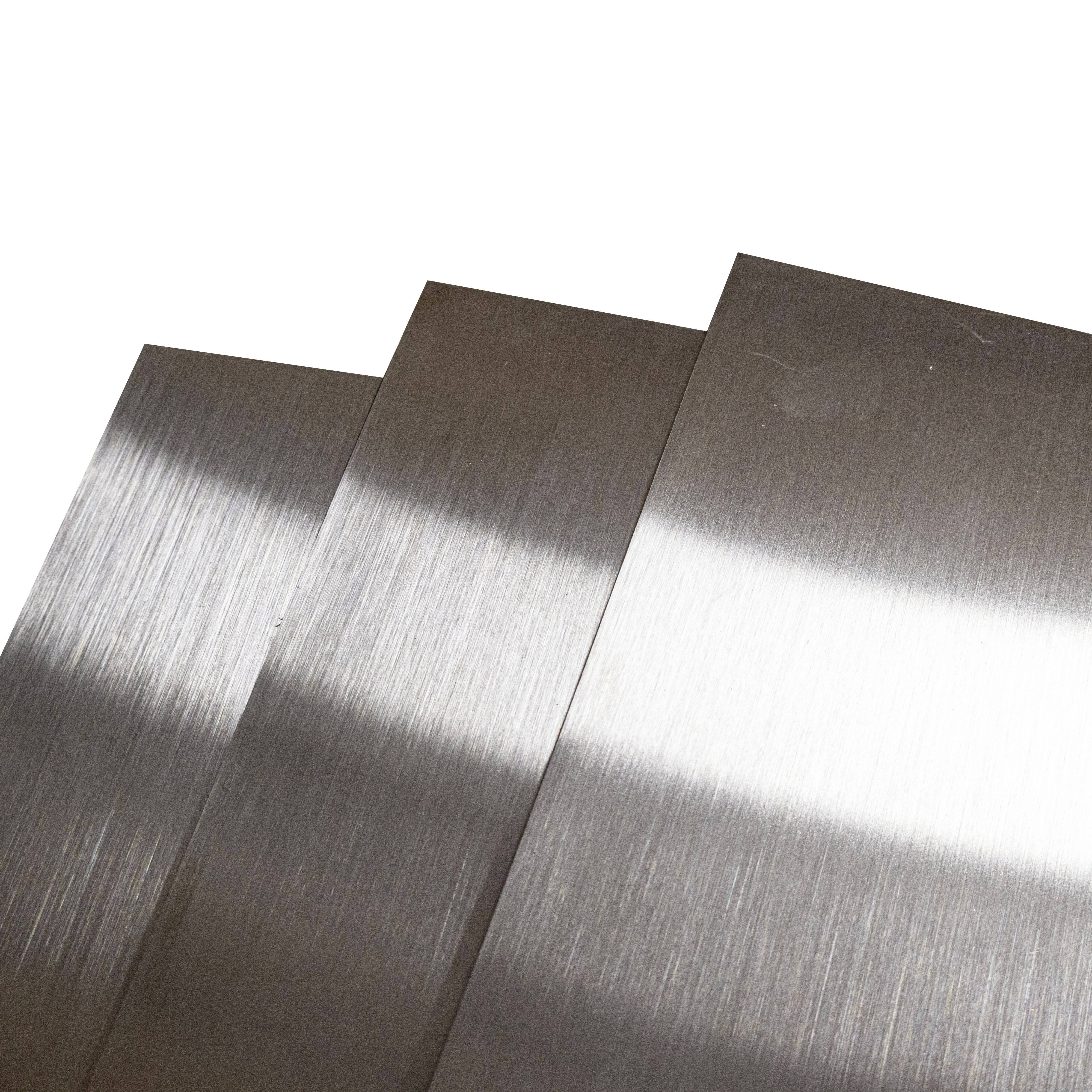

- Laminación en Caliente y Fría – Las chapas se forman con un grosor y dimensiones precisos.

- Tratamiento térmico: el recocido mejora las propiedades mecánicas y la resistencia a la corrosión.

- Acabado Superficial – El desescamado y pulido mejoran la apariencia y longevidad.

- Pruebas de Calidad – Incluyen análisis químico, pruebas de tracción y inspección ultrasónica para cumplir con los estándares ASTM B127.

- Tamaños y Grosores Personalizados – Ajustados a aplicaciones específicas de la industria.

- Descuentos por Pedidos al Por Mayor – Precios competitivos para proyectos a gran escala.

- Entrega Rápida y Suministro Confiable – Garantizando la finalización oportuna del proyecto.

- Cumplimiento con los Estándares de la Industria – Apegándose a las especificaciones ASTM, ASME e ISO.

Placas de Monel 400 de Grado Industrial - Rendimiento Duradero y Largo

Introducción a las Placas de Monel 400

Las placas de Monel 400 son ampliamente reconocidas por su excelente resistencia a la corrosión, su fuerza mecánica y durabilidad en entornos industriales severos. Como aleación de níquel-cobre, el Monel 400 es altamente resistente al agua salada, ácidos y soluciones alcalinas, lo que lo convierte en un material preferido en las industrias marítima, química y de generación de energía.

Resumen del Material

El Monel 400 (UNS N04400) es una aleación de solución sólida compuesta principalmente de níquel y cobre, proporcionando una excepcional resistencia a la corrosión y una alta fuerza mecánica incluso en condiciones extremas.

Composición química

Características Principales de las Placas de Monel 400

Aplicaciones de placas de Monel 400

Debido a sus propiedades mecánicas y de resistencia a la corrosión superiores, las placas de Monel 400 son ampliamente utilizadas en diversas industrias:

1. Industria Marítima y Offshore

2. Industria de Procesamiento Químico

3. Generación de Energía

4. Aeronáutica y Automotriz

5. Industria del Petróleo y el Gas

Proceso de fabricación de placas de Monel 400

La producción de placas de Monel 400 implica varios pasos clave para garantizar una alta calidad y durabilidad:

Demanda del Mercado y Requisitos del Cliente

La demanda de placas de Monel 400 está aumentando debido a su rendimiento sin igual en entornos agresivos. Los clientes a menudo buscan:

¿Qué es eso?

¿Cuánto tiempo dura la entrega?

Depende de la cantidad del pedido, 10-30 días para pedidos pequeños. Para pedidos grandes, tarda 60 días.

¿Aceptan producción OEM/ODM?

¡Sí! Aceptamos producción OEM/ODM. Puedes enviarnos tus muestras o dibujos.

¿Cómo controlan la calidad de sus productos? ¿Las propiedades químicas de los productos cumplen con los estándares de calidad?

Con un equipo de calidad profesional, planificación avanzada de la calidad del producto, implementación estricta y mejora continua, emitiremos un certificado de inspección de calidad del producto, incluido el informe de análisis químico.

¿Puede su empresa proporcionar datos técnicos detallados y dibujos?

Sí, puedes. Por favor, dinos los productos y aplicaciones que necesitas, y te enviaremos datos técnicos detallados y dibujos para tu evaluación y confirmación.

¿Cómo manejan el servicio antes y después de la venta?

Tenemos un equipo de negocios profesional que trabajará uno a uno para proteger tus necesidades de producto, y si tienes alguna pregunta, él puede responderlas por ti.

¿Puedo visitar tu fábrica antes de hacer un pedido?

Sí, eres bienvenido a visitar nuestra fábrica. Nos alegra tener la oportunidad de conocernos.

¿Dónde está tu base de producción?

Fabricamos nuestros productos en Jiangsu, China y los enviamos desde China a tu país lo antes posible, lo cual generalmente depende de los requisitos del producto y la cantidad.

¿Puede enviar muestras?

Sí, podemos hacerlo.