Επιλογή διαφόρων συμπεπλεγμένων ** :

Το νίτρο/ηλεκτρόδιο μπορεί να περιέχει διαφορετικές αναλογίες σιδήρου, νικελίου, άλουμινου, χάλκου, τιτανίου και άλλων στοιχείων όπως απαιτείται για να προσαρμοστεί σε διαφορετικά υποκείμενα υλικά και συνθήκες συνδεσιμώσεως.

Καλή απόδοση καλύψεως:

Μπορεί να παρέχει ομοιόμορφο καλυμμένο μέταλλο για να εξασφαλίσει την ποιότητα και την ομαλότητα των συνδεσιμών συρραφτικών συνδέσεων.

Αριστούργητες μηχανικές ιδιότητες:

Οι συνδεσιμές συνδέσεις μπορούν να διατηρούν υψηλή ισχύ, αντοχή και αντοξυδωτικότητα, κατάλληλες για διάφορα εργασιακά περιβάλλοντα.

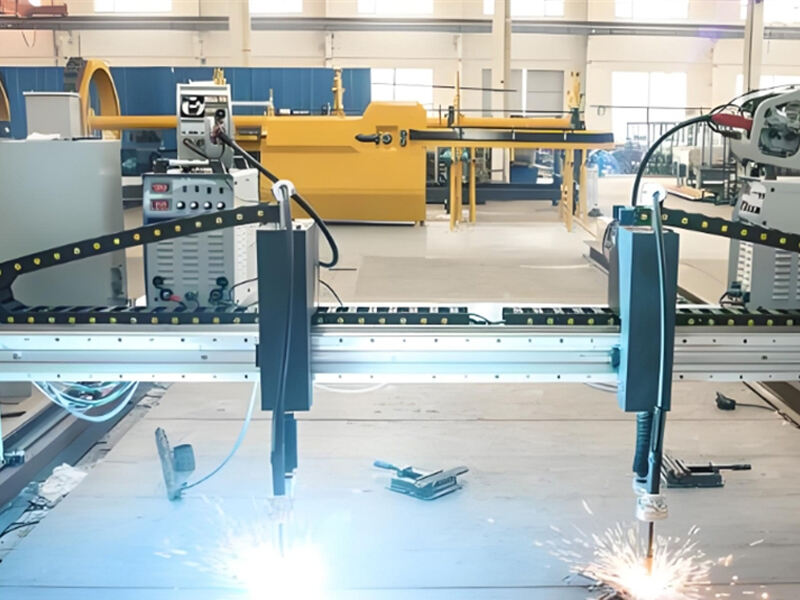

Εύκολη στη λειτουργία:

Σύγχρονη σχεδιασμός νιτρών/ηλεκτρόδιων λαμβάνει υπόψη τη χρήση του χρήστη, με καλή έναρξη αρκού, σταθερότητα αρκού και λιγότερα σπατάλια.

Ευρεία εφαρμογή:

Κατάλληλοι για διάφορες μεθόδους συνδεσιμώσεως, όπως χειροκίνητη αρκική συνδεσιμώσεις (SMAW), φυσική προστασία αρκού (GMAW/MIG, FCAW), συνδεσιμώσεις με τουνγκστενίου σε αργόνιο (GTAW/TIG) κ.λπ.

Οικονομικά:

Με τη βελτίωση της συνταγής και της διαδικασίας κατασκευής, μεγιστοποιείται η κοστολογική αποτελεσματικότητα και μειώνονται οι κόστος συνδεσιμώσεων.

Μέτρηση υπερύψωσης θερμοκρασίας:

Έχει την ικανότητα να αντέξει ακραίες θερμοκρασίες, ακόμη και πάνω από 2000°C.

Μακροχρόνια σταθερότητα:

Συντηρούνται οι σταθερές χαρακτηριστικές εξόδου ακόμη και σε υψηλές θερμοκρασίες.

Εξαιρετική αντοχή στην οξείδωση:

Μειώνει τα προβλήματα γηράσκων λόγω οξείδωσης.