Efficient Heating Solutions: 0Cr23Al5 and 0Cr21Al4 FeCrAl Alloy Resistance Wires

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

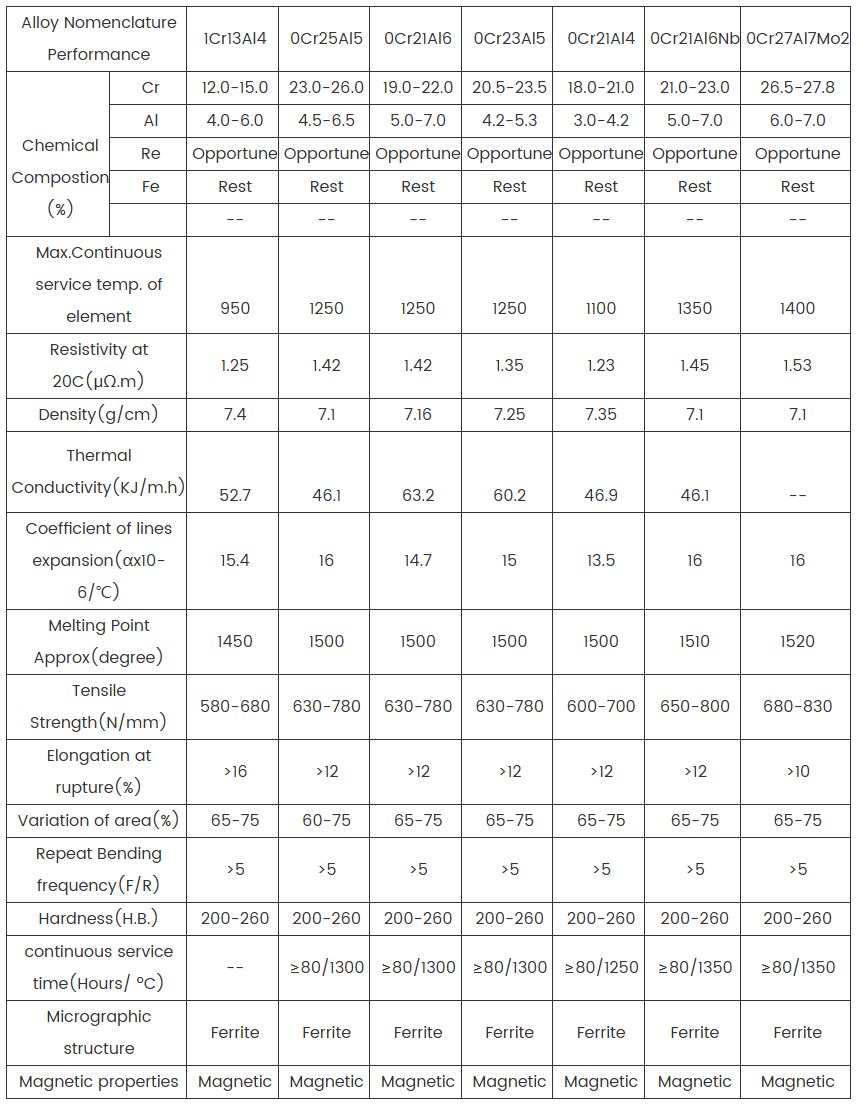

0Cr23Al5: This alloy contains 23% chromium and 5% aluminum. It offers excellent oxidation resistance and can operate in high-temperature environments of up to 1300°C. Its high chromium content allows it to retain its strength and integrity under continuous high-heat conditions, which is critical for long-term applications in industrial heating systems.

-

0Cr21Al4: This alloy consists of 21% chromium and 4% aluminum. Although it has slightly less chromium than 0Cr23Al5, it still provides robust resistance to oxidation and high-temperature stability, capable of withstanding temperatures up to 1200°C. Its balance of properties makes it suitable for general industrial heating applications where the temperature demands are slightly lower but still significant.

-

Industrial Heating Elements: Both 0Cr23Al5 and 0Cr21Al4 are commonly used in the production of industrial heating elements for furnaces, kilns, and heat treatment processes. These alloys' high resistance to oxidation and ability to maintain mechanical strength in extreme heat make them ideal for these environments, where temperatures can reach upwards of 1000°C.

-

Electric Heaters: In electric heating appliances, such as space heaters, water heaters, and ovens, FeCrAl alloys are a go-to material for resistance wires. The alloys' stability at high temperatures ensures that these appliances can operate safely and efficiently over extended periods.

-

Power Generation: FeCrAl alloys, particularly 0Cr23Al5, are used in power plants for applications such as heating elements in steam generators and exhaust systems. Their resistance to oxidation and ability to maintain efficient heat generation at high temperatures ensures that power generation processes are both reliable and cost-effective.

-

Laboratory and Scientific Equipment: Heating elements in laboratory furnaces, sterilizers, and other scientific equipment often require materials that can withstand precise and high temperatures. 0Cr21Al4 is frequently chosen for these applications due to its reliability and stability under controlled, high-heat conditions.

-

Automotive and Aerospace: In automotive and aerospace applications, particularly for exhaust systems and catalytic converters, these alloys' high-temperature resistance and corrosion resistance are highly valued. Their use helps maintain performance in environments subject to extreme heat and corrosion.

-

0Cr23Al5: This alloy contains 23% chromium and 5% aluminum, making it ideal for use in environments where higher temperatures and superior oxidation resistance are required. It can operate continuously at temperatures up to 1300°C and offers exceptional resistance to corrosion and oxidation. Its high chromium content makes it particularly suitable for industrial heating elements, power generation applications, and processes with extreme temperature demands.

-

0Cr21Al4: With 21% chromium and 4% aluminum, 0Cr21Al4 provides slightly lower oxidation resistance compared to 0Cr23Al5, but still offers high performance in industrial heating applications. It is suitable for environments with temperatures up to 1200°C and is used where a slightly lower cost solution is needed without compromising on heat resistance and mechanical strength.

-

Raw Material Selection and Alloying: The first step in the production process is selecting high-quality raw materials. The alloy is created by combining iron, chromium, and aluminum in precise proportions, usually using a melting process in an induction furnace. This process ensures that the alloy composition is consistent throughout.

-

Casting: Once the alloy has been melted, it is cast into billets or ingots. The casting process is controlled to ensure uniform distribution of the elements and to minimize any impurities that could affect the performance of the final product.

-

Extrusion and Drawing: After the material has solidified, it undergoes extrusion and drawing processes to produce fine wires. During these processes, the alloy is stretched to the desired diameter, which ensures the resistance wire will have the correct properties for electrical and thermal performance.

-

Heat Treatment: The wires are then heat-treated to optimize their mechanical properties and electrical resistance. Annealing or other heat treatments are used to relieve internal stresses, enhance ductility, and improve the alloy's performance at high temperatures.

-

Quality Control and Testing: Every batch of FeCrAl alloy wires undergoes rigorous quality control tests. These tests assess oxidation resistance, electrical resistance, mechanical strength, and stability at high temperatures. Only materials that meet the specified standards are approved for use in industrial applications.

In industrial and commercial heating applications, selecting the right material for resistance wires is critical to achieving long-lasting, energy-efficient, and reliable performance. FeCrAl (Iron-Chromium-Aluminum) alloys, specifically 0Cr23Al5 and 0Cr21Al4, have emerged as some of the most efficient and durable options for high-temperature resistance wires. These alloys offer an optimal balance of heat resistance, oxidation resistance, and mechanical strength, making them ideal for a wide range of heating applications. In this article, we will delve into the materials' characteristics, their applications, the specific grades, manufacturing processes, and how these alloys meet user demands for efficient heating solutions.

Material Introduction

FeCrAl alloys are primarily composed of iron, chromium, and aluminum. The addition of chromium enhances the material's resistance to oxidation, while aluminum significantly improves oxidation resistance, making these alloys well-suited for high-temperature environments where conventional metals would degrade quickly.

Applications

FeCrAl alloys, particularly 0Cr23Al5 and 0Cr21Al4, are widely used in applications where resistance wires need to perform efficiently and reliably in high-temperature conditions. The following are some of the primary sectors that benefit from these alloys:

Grades and Specifications

FeCrAl alloys come in several grades, with 0Cr23Al5 and 0Cr21Al4 being two of the most widely used. Each alloy has distinct properties that make it suitable for specific applications:

Manufacturing Process

The production of FeCrAl alloy resistance wires involves several key stages to ensure that the final product meets the required specifications for performance and durability. Below is a typical manufacturing process for these alloys:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.