Durable and Efficient Heating Elements: Cr30Ni70 and Cr20Ni35 NiCr Alloy Resistance Wires

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

-

Cr30Ni70 (30% Chromium, 70% Nickel)

- Excellent high-temperature resistance, capable of operating up to 1250°C

- Superior oxidation and corrosion resistance in both air and controlled environments

- High electrical resistivity, making it ideal for precision heating applications

- Good mechanical strength and flexibility for various heating element designs

-

Cr20Ni35 (20% Chromium, 35% Nickel, Balance Iron)

- High thermal efficiency and stable resistance properties

- Good mechanical workability, making it suitable for wire coils and strip heating elements

- Lower operating temperature than Cr30Ni70 but offers better affordability and versatility

- Resistant to thermal shock and mechanical fatigue, ensuring long service life

-

Industrial Furnaces and Kilns

- Cr30Ni70 is used in high-temperature furnaces for metal heat treatment, ceramics, and glass processing.

- Cr20Ni35 is used in medium-temperature furnaces where cost-effective heating solutions are required.

-

Electric Heating Elements

- Common in industrial heaters, ovens, and radiant heating systems.

- Used in household appliances such as toasters, hair dryers, and electric stoves due to their efficient heat generation.

-

Resistive Load Applications

- Employed in load banks and braking resistors for electrical equipment testing and industrial machinery.

-

Aerospace and Automotive Industries

- Applied in de-icing systems and high-temperature sensors in aircraft and automotive exhaust systems.

-

Laboratory and Scientific Equipment

- Used in high-precision heating devices such as sterilizers, analytical instruments, and laboratory ovens.

-

Long Service Life

- The oxidation and corrosion resistance of Cr30Ni70 and Cr20Ni35 ensures extended operational life, reducing maintenance costs.

-

Energy Efficiency

- High electrical resistivity contributes to efficient heat conversion, making these alloys ideal for sustainable and cost-effective heating solutions.

-

Stable Performance at High Temperatures

- These alloys maintain their structural integrity and resistivity even in extreme heat environments, ensuring consistent performance.

-

Mechanical Strength and Workability

- Both alloys can be easily processed into different shapes, including wires, coils, and strips, catering to various heating applications.

Nickel-Chromium (NiCr) alloys are widely recognized for their exceptional resistance to high temperatures, oxidation, and corrosion. These properties make them an ideal choice for heating elements in various industrial and commercial applications. Among NiCr alloys, Cr30Ni70 and Cr20Ni35 stand out for their unique balance of durability, efficiency, and electrical resistance, making them highly suitable for high-performance heating solutions.

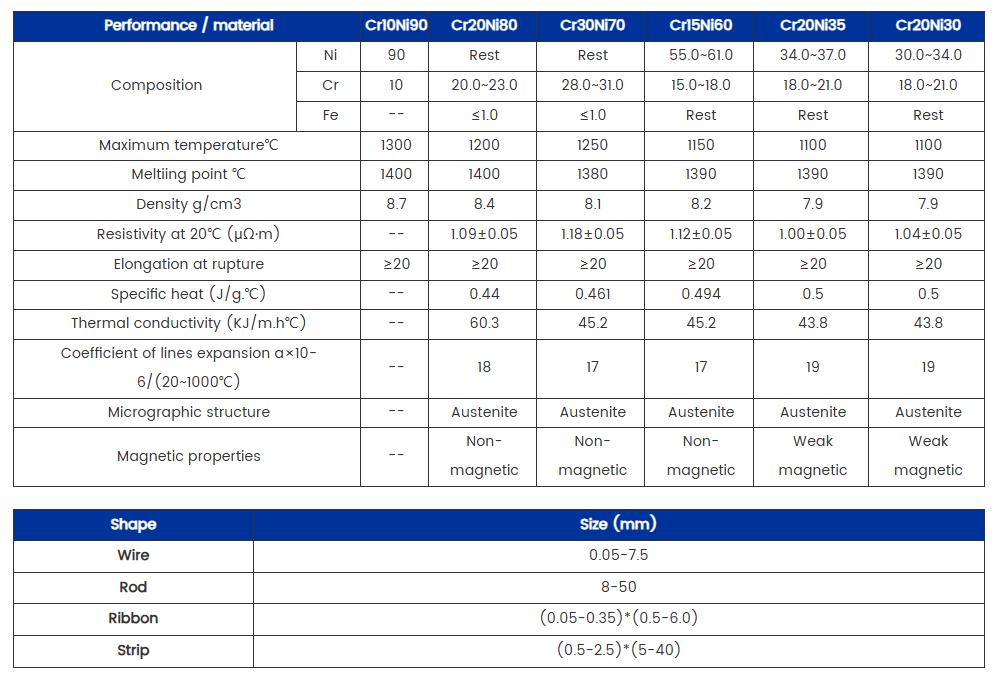

Material Properties of Cr30Ni70 and Cr20Ni35

Applications of Cr30Ni70 and Cr20Ni35 NiCr Resistance Wires

Due to their outstanding heat resistance and oxidation stability, these NiCr alloys are widely used in various industrial and commercial heating applications:

Meeting User Demands

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.