Durable and Corrosion-Resistant Foam Nickel for Industrial Filtration and Chemical Processing

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

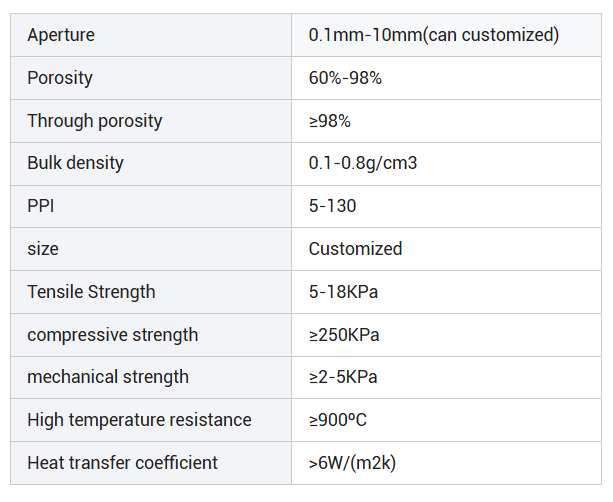

- Specification

- About Us

- FAQs

- Recommended Products

-

Advanced Filtration for Industrial Processes

- Foam nickel is widely used as a high-performance filter in industries such as oil refining, petrochemicals, and metallurgy.

- Its porous structure effectively removes impurities and particulates from liquids, gases, and chemical solutions, ensuring cleaner processes and higher-quality outputs.

-

Catalyst Support in Chemical Processing

- In chemical processing plants, foam nickel acts as a catalyst support material, facilitating efficient chemical reactions while withstanding high temperatures and corrosive substances.

- Its large surface area enhances catalytic efficiency, making it an ideal choice for hydrogenation reactions, fuel cells, and energy production.

-

Gas Diffusion and Purification

- Foam nickel is used in gas diffusion applications for air purification, exhaust treatment, and industrial ventilation systems.

- Its uniform pore structure enables effective gas flow, improving reaction rates and system efficiency in power plants and chemical facilities.

-

Electrolyte Filtration in Battery Production

- Foam nickel serves as a filter material in electrolyte solutions, ensuring purity and stability in lithium-ion and nickel-based batteries.

- By preventing contamination, it helps enhance battery performance and longevity.

- Exceptional Corrosion and Heat Resistance: Foam nickel withstands high temperatures and aggressive chemicals, ensuring reliable long-term operation.

- High Porosity for Efficient Filtration: The open-cell design maximizes filtration capacity, making it ideal for liquid and gas purification.

- Lightweight and Durable: Unlike traditional metal filters, foam nickel is lightweight yet highly durable, reducing maintenance costs and operational downtime.

- Eco-Friendly and Recyclable: Foam nickel is a sustainable solution, offering reusability and recyclability for environmentally conscious industries.

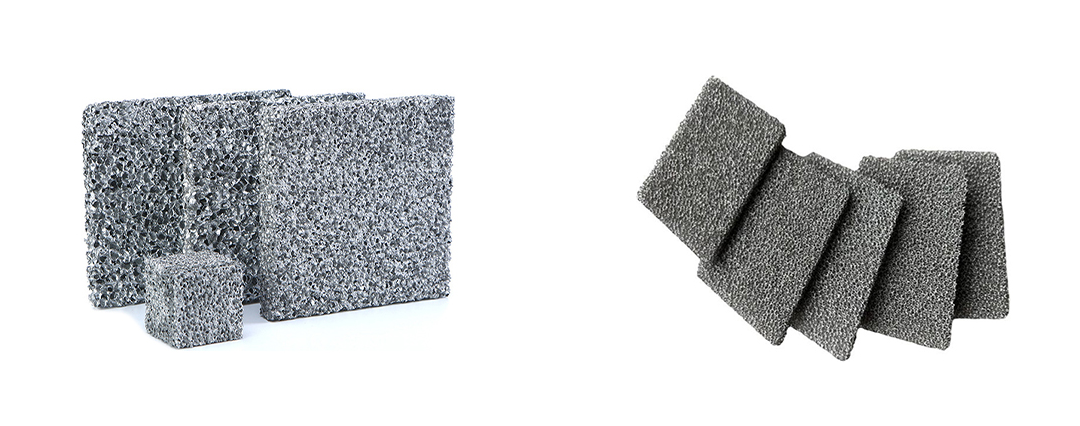

Foam nickel is a highly versatile material known for its exceptional durability, high porosity, and outstanding corrosion resistance, making it an essential component in industrial filtration and chemical processing. Its open-cell structure allows for efficient fluid and gas flow, while its chemical stability ensures long-lasting performance in harsh environments. As industries continue to demand advanced materials for high-efficiency filtration and processing, foam nickel has become a preferred solution due to its mechanical strength, heat resistance, and adaptability.

Applications of Foam Nickel in Industrial Filtration and Chemical Processing

Meeting Industry Needs with Foam Nickel Solutions

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.