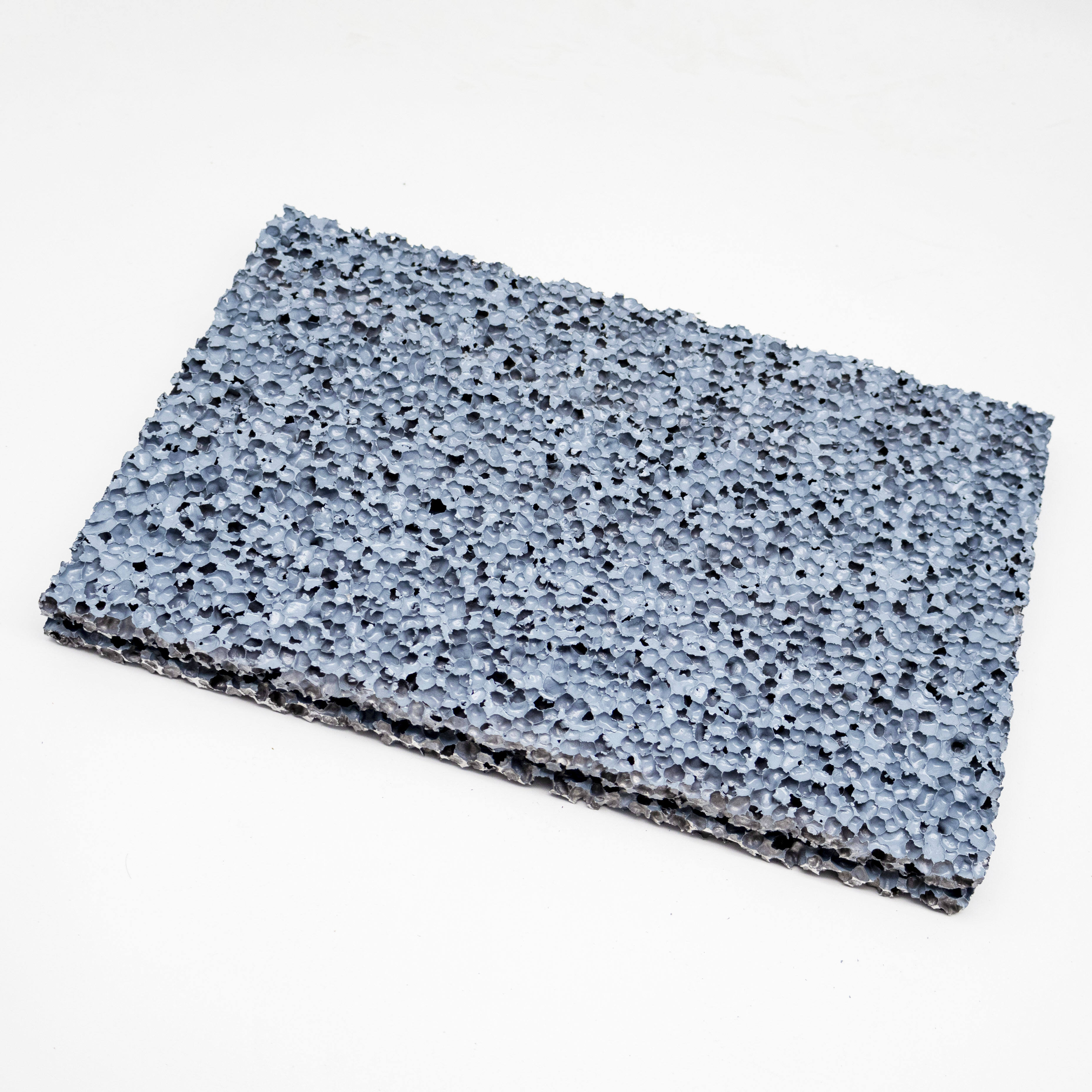

Durable and Corrosion-Resistant Foam Aluminum for Marine and Industrial Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

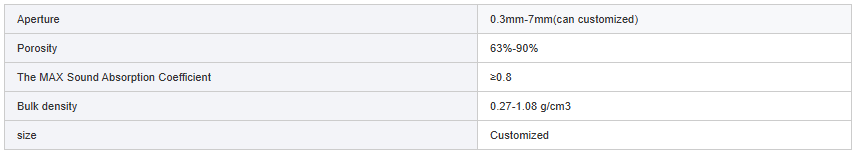

- Specification

- About Us

- FAQs

- Recommended Products

-

Corrosion-Resistant Components for Marine Environments

- In the marine industry, foam aluminum is utilized in the construction of vessel hulls, underwater structures, and offshore platforms, where resistance to saltwater corrosion is crucial.

- Its corrosion-resistant properties allow it to withstand the harsh marine environment, ensuring extended service life and reducing the need for frequent maintenance in ships, boats, and marine equipment.

-

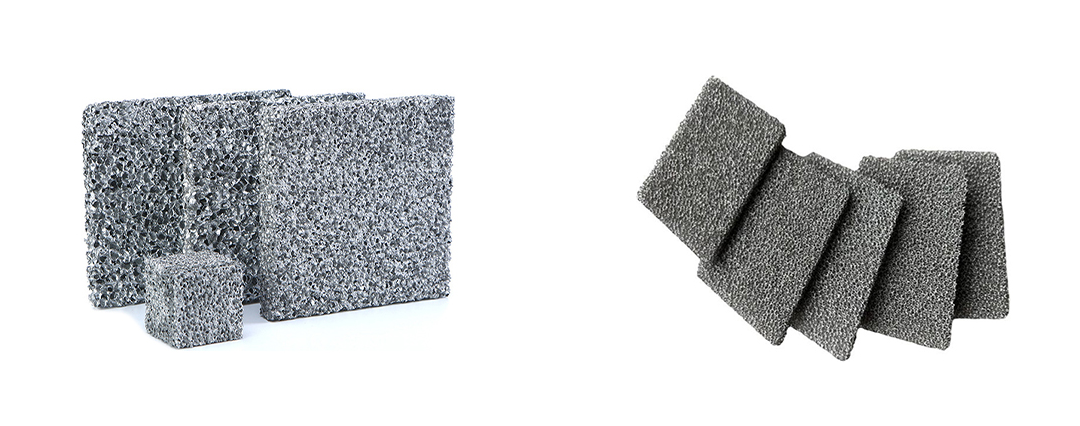

Lightweight Structural Components in Shipbuilding

- Foam aluminum is commonly used in lightweight structural components in shipbuilding and marine engineering.

- It helps reduce the overall weight of vessels, improving fuel efficiency and performance while maintaining structural integrity. This is particularly beneficial in naval ships, cargo ships, and luxury yachts that prioritize both strength and weight savings.

-

Thermal Management in Industrial Equipment

- In industrial applications, foam aluminum is used for heat dissipation and thermal management in heavy-duty machinery, equipment enclosures, and power plants.

- Its thermal conductivity ensures efficient heat transfer, while the porous structure enhances its ability to absorb and dissipate heat, protecting sensitive equipment from damage caused by excessive temperatures.

-

Energy Absorption and Protection in Industrial Safety

- Foam aluminum’s impact resistance and energy absorption capabilities make it an ideal material for safety equipment such as industrial barriers, protective shields, and crash protection systems.

- Its shock-absorbing properties help prevent damage to machinery and equipment during accidents and industrial operations that involve heavy impacts.

- Corrosion Resistance: Foam aluminum’s resistance to saltwater corrosion makes it ideal for marine environments, where materials are constantly exposed to harsh and aggressive elements.

- Lightweight Strength: Despite being lightweight, foam aluminum offers exceptional strength and structural integrity, making it suitable for a wide range of marine and industrial uses without sacrificing performance.

- Thermal Efficiency: With its excellent thermal conductivity, foam aluminum plays a crucial role in temperature management for machinery, industrial equipment, and marine vessels, helping to reduce the risk of overheating and ensuring continuous operation.

- Sustainability: As a recyclable material, foam aluminum supports eco-friendly practices, reducing environmental impact while offering long-term durability and performance.

Foam aluminum is a lightweight, durable, and corrosion-resistant material that has become essential in a wide range of marine and industrial applications. Its unique porous structure, combined with the inherent properties of aluminum, makes foam aluminum an ideal solution for environments that demand high strength, resistance to harsh conditions, and superior performance. As industries increasingly prioritize sustainability, energy efficiency, and long-term durability, foam aluminum offers unmatched versatility and protection for critical applications.

Applications of Foam Aluminum in Marine and Industrial Sectors

Meeting Industry Needs with Foam Aluminum Solutions

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.