Nickelbasis-Monel 400 Legierung – Hochleistungs-Material für kritische Industrien

Wir bieten fabrikdirekte Preise und spezielle Rabatte für Großaufträge. Unabhängig davon, ob Sie kleine oder große Mengen benötigen, werden unsere Produkte schnell verschifft, um einen zuverlässigen Versorgungsfluss für industrielle Projekte weltweit sicherzustellen.

- Übersicht

- Spezifikation

- ANWENDUNGEN

- Häufig gestellte Fragen

- Empfohlene Produkte

- Nickel (Ni): ≥ 63%

- Kupfer (Cu): 28-34%

- Eisen (Fe): ≤ 2,5%

- Mangan (Mn): ≤ 2,0%

- Silizium (Si): ≤ 0,5%

- Kohlenstoff (C): ≤ 0,3%

- Schwefel (S): ≤ 0,024%

- In Seewasserleitungsanlagen, Schiffsbau und Offshore-Ölplattformen eingesetzt.

- Widerstandsfähig gegen Salzwasserkorrosion, Pitting und Biofouling, wodurch eine langfristige Leistung gewährleistet wird.

- Ideal für Wärmetauscher, Kondensatoren und Wellen in maritimen Umgebungen.

- In Speichertanks, Ventilen und Rohrleitungssystemen zur Behandlung saurer oder basischer Substanzen eingesetzt.

- Beständig gegen Schwefelsäure, Fluorsäure und andere aggressive Chemikalien.

- In Reaktoren, Destillationskolonnen und Druckbehältern verwendet.

- In Hochtemperatur-Komponenten von Motoren, Treibstofftanks und Abgasanlagen verwendet.

- Hält thermische Ausdehnung und extreme Umweltbedingungen aus.

- Bietet eine leichte, aber dennoch robuste tragende Unterstützung für Luft- und Raumfahrtanwendungen.

- Wird in Turbinen, Wärmetauschern und Komponenten von Kernreaktoren eingesetzt.

- Behält hohe Festigkeit und Widerstand gegen strahlungsinduziertes Brüchigkeitsverhalten bei.

- Garantieren eine langanhaltende Leistung bei extremen Temperaturen und Drücken.

- Wird in Bohrwerkzeugen, Pipelines und Offshore-Fördereinrichtungen eingesetzt.

- Hält bei Hochdruck- und Hochtemperaturbedingungen beim Tiefseebohren durch.

- Garantiert dichteschlussfähige und korrosionsbeständige Leistung unter harten Bedingungen.

- Auswahl der Rohstoffe: Hochreines Nickel und Kupfer werden sorgfältig vermischt.

- Schmelzen & Gießen: Die Legierung wird in einem Vakuum oder Induktionsofen geschmolzen, um eine gleichmäßige Zusammensetzung zu erreichen.

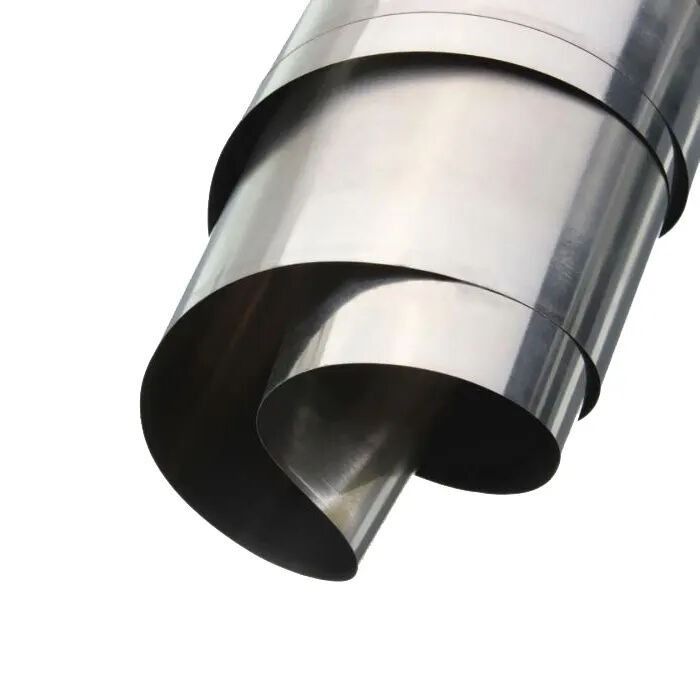

- Warm- und Kaltwalzen: Verarbeitet zu Blechen, Platten, Röhren, Rohren, Stäben, Stangen und Drähten.

- Wärmebehandlung & Annealed: Verbessert die mechanischen Eigenschaften und Korrosionsbeständigkeit.

- Bearbeitung & Fertigung: Maßgeschnittene Komponenten werden auf Basis von Branchenanforderungen hergestellt.

- Oberflächenbearbeitung & Beschichtung: Durch Ätzung, Polieren oder spezielle Beschichtungen wird die Haltbarkeit verbessert.

- Qualitätskontrolle & Prüfung: Enthält chemische Analyse, mechanische Prüfungen und zerstörungsfreie Untersuchungen, um die ASTM B127 und ASTM B164 Standards einzuhalten.

Monel 400 ist eine hochleistungsfähige Nickel-Kupfer-Legierung (UNS N04400), die für ihre außergewöhnliche Korrosionsbeständigkeit, mechanische Stärke und thermische Stabilität bekannt ist. Dadurch wird es zu einem bevorzugten Material in der Schifffahrt, Chemieverarbeitung, Luft- und Raumfahrt, Energieerzeugung sowie Öl- und Gasindustrie. Aufgrund ihrer Fähigkeit, strenge Umgebungen zu überstehen, wird Monel 400 weit verbreitet in Wärmetauschern, Rohrsystemen, Pumpen und industriellen Anlagen eingesetzt.

Materialübersicht – Monel 400 (UNS N04400)

Monel 400 besteht hauptsächlich aus Nickel (≥63%) und Kupfer (28-34%) und bietet eine ausgezeichnete Beständigkeit gegen saure, basische und salzhaltige Umgebungen. Es behält seine mechanischen Eigenschaften selbst bei hohen Temperaturen und Drücken bei, was es ideal für kritische industrielle Anwendungen macht.

Chemische Zusammensetzung von Monel 400

Wichtige Eigenschaften von Monel 400

✔ Hervorragende Korrosionsbeständigkeit: Hält stand gegen Seewasser, Säuren, Lauge und oxidierende Substanzen.

✔ Hochtemperaturfestigkeit: Funktioniert gut in extrem heißen und druckintensiven Umgebungen.

✔ Ausgezeichnete mechanische Dauerhaftigkeit: Bietet überlegene Stoßfestigkeit und Zähigkeit.

✔ Gute Schweiß- und Bearbeitbarkeit: Leicht zu komplexen industriellen Komponenten verarbeitbar.

✔ Nichtrückständig: Bleibt in Hochfrequenz- und elektrischen Anwendungen stabil.

Anwendungen des Monel 400 Legierungs

1. Seeverkehr & Offshore-Industrie

2. Chemische und Petrochemische Verarbeitung

3. Luft- und Raumfahrtindustrie

4. Energieerzeugung & Nuklearindustrie

5. Öl- & Gas-Industrie

Fertigungsprozess der Monel 400 Legierung

Fragen und Antworten:

Wie lange dauert die Lieferung?

Es hängt von der Menge der Bestellung ab, 10-30 Tage für kleine Bestellungen. Für große Bestellungen dauert es 60 Tage.

Akzeptieren Sie OEM/ODM Produktion?

Ja! Wir akzeptieren OEM/ODM Produktion. Sie können uns Ihre Proben oder Zeichnungen senden.

Wie kontrollieren Sie die Qualität Ihrer Produkte? Erfüllen die chemischen Eigenschaften der Produkte die Qualitätsstandards?

Mit einem professionellen Qualitäts TEAM, fortschrittlicher Produktqualitätsplanung, strenger Umsetzung und kontinuierlicher Verbesserung werden wir ein Produktprüfzertifikat ausstellen, einschließlich eines Chemie-Analyseberichts.

Kann Ihre Firma detaillierte technische Daten und Zeichnungen bereitstellen?

Ja, das können Sie. Bitte teilen Sie uns mit, welche Produkte und Anwendungen Sie benötigen, und wir werden Ihnen detaillierte technische Daten und Zeichnungen zur Bewertung und Bestätigung zusenden.

Wie behandeln Sie den Vorverkauf und den Kundenservice nach dem Verkauf?

Wir haben ein professionelles Geschäftsteam, das einzeln arbeitet, um Ihre Produktbedürfnisse zu schützen, und wenn Sie Fragen haben, kann er diese für Sie beantworten!

Kann ich Ihre Fabrik besuchen, bevor ich eine Bestellung aufgebe?

Ja, Sie sind herzlich willkommen, unsere Fabrik zu besuchen. Wir freuen uns über die Gelegenheit, einander kennenzulernen.

Wo befindet sich Ihre Produktionsstätte?

Wir produzieren unsere Produkte in Jiangsu, China, und verschiffen sie so schnell wie möglich aus China in Ihr Land, was normalerweise von Ihren Produktnachforderungen und der Menge abhängt.

Können Sie mir Proben schicken?

Ja, das können wir.