Nickel Alloy ERNiCrMo-4 (C-276) SvejsningsTråd – Bestil Nu for RabatPris

Mere: ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6

- Oversigt

- Anbefalede produkter

Introduktion til ERNiCrMo-4 (C-276) Veldningstråd

ERNiCrMo-4 (C-276) vindingtråd er en højydelses nickel-chrom-molybdæn alloy, der er udformet til at sværge korrosionsbestandige materialer anvendt i ekstreme miljøer. Den er vidt kendt for sin fremragende modstand mod syrer, chlorider og oxidationsmidler, hvilket gør den ideal til kemisk bearbejdning, energiproduktion, maritime, luftfart og olie & gas industrier.

Vi tilbyder priser direkte fra fabrikken med specielle rabatter på store bestillinger. Uanset om du har brug for små eller store mængder, er vores ERNiCrMo-4 veldningstråd klar til umiddelbar levering, hvilket sikrer en pålidelig forsyning til industriprojekter over hele verden.

Materialeoversigt: Egenskaber ved ERNiCrMo-4 (C-276) Svovningstråd

ERNiCrMo-4 (C-276), også kendt som Hastelloy® C-276, yder fremragende prestationer i krævende anvendelser på grund af dets unikke materialeegenskaber:

✔ Fremragende korrosionsmodstand – Modstandsdygtig mod punktkorrosion, spaltkorrosion og spændingskorrosionsbrud i højst aggressive og kloridrigne miljøer.

✔ Højtemperaturstyrke – Beholder mekanisk integritet ved temperature op til 1093°C (2000°F).

✔ Fremragende sværbarhed – Danner rene, stærke og fejl frie svarge med minimal varmestrækning.

✔ Modstand mod skarpe kemikalier – Fungerer godt i oxidations- og reduktionsmiljøer, herunder hydrochlorisk, sulfursyre og nitersyre.

✔ Høj holdbarhed og styrke – Kan klare ekstrem tryk og termiske variationer i industrielle anvendelser.

Disse egenskaber gør ERNiCrMo-4 veldedningstråd til en fremragende valgmulighed for industrier, der kræver pålidelige og varighedsstærke veldninger under strenge betingelser.

Branchestandarder og Specificeringer

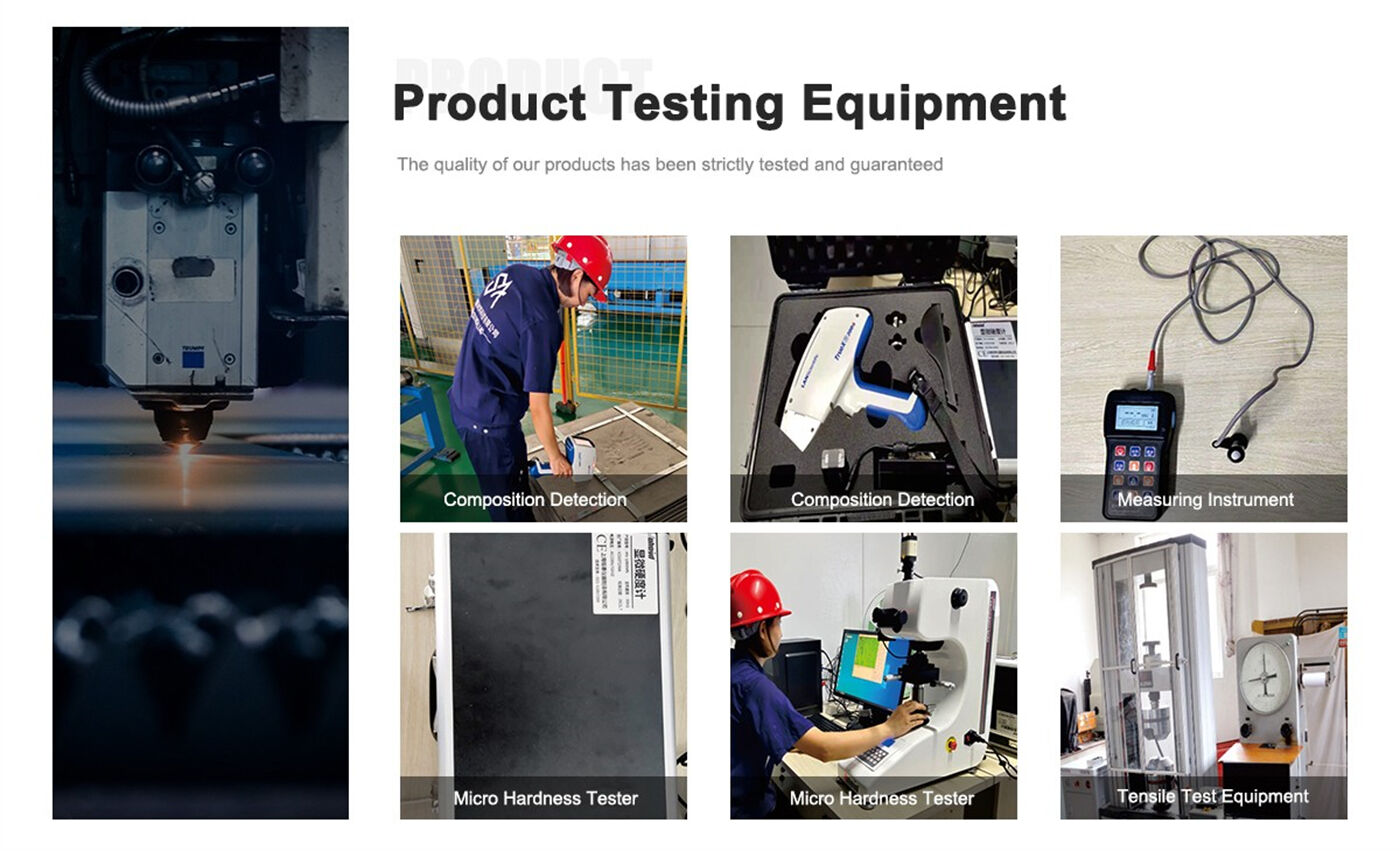

Vores ERNiCrMo-4 (C-276) veldedningstråd fremstilles i overensstemmelse med internationale standarder, hvilket sikrer høj kvalitet i kritiske veldningssituationer.

Standard Specificaton

AWS A5.14 ERNiCrMo-4

UNS Nummer N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

Disse certifikater garanterer, at vores veldedningstråd opfylder strenge branchekrav til sikkerhed, holdbarhed og effektivitet.

Anvendelser af ERNiCrMo-4 (C-276) Svartertråd

1. Kemisk procesindustri

Surtebeholdere og rørledninger – Kan klare korrosive kemikalier som hydroklorisk og sulfursyre.

Varmetandser og trykkefterbehandlingsanlæg – Leverer holdbarhed i højtemperatur- og højtryksmiljøer.

Kemiske reaktorer og blandingsudstyr – Forhindre kontaminering og korrosionsfejl.

2. Energiproduktion og kerneteknologisk industri

Kernereaktorkomponenter – Sikrer strålingstilskydning og varmebestandighed for kraftværker.

Damp- og gasruder – Tilbyder oxidationstilskydning under højtemperaturaforhold.

Fyringsrør og varmegenoptrapningsanlæg – Forhindre termisk cyklus og korrosionsbeskadigelse.

3. Olie & Gas Industri

Offshoreplatforme og rørledninger – Modstandsdygtige over for sulfidstressspaltning (SSC) og hydrogentræthed.

LNG- og kryogenteknologianvendelser – Vedligeholder mekanisk stabilitet ved ekstremt lave temperaturer.

Råolieforarbejdningsenheder – Kan klare høj-sulfur- og surmiljøer.

4. Luftfart og marineingeniørvidenskab

Strømtrækkerkomponenter – Ideel til højtemperatur- og højtryksapplikationer inden for luftfarten.

Skibsværft og havvandsanlæg – Leverer korrosionsbeskyttelse i marine miljøer.

5. Fødevare- og Farmaceutindustri

Hygiejnisk velding til fødevarebehandlingsudstyr – Sikrer hygiejnisk og kontaminationsfri produktion.

Sterilisering og medicinsk udstyr – Tilbyder biokompatibilitet og modstandsdygtighed over for sterilisering.

Hvorfor vælge vores ERNiCrMo-4 (C-276) Svejsningstråd?

✅ Rabat på store mængder – Specielle tilbud for store ordrer og gros handelskunder.

✅ Certificeret høj kvalitet legering – Opfylder AWS, ASTM og ISO branchestandarder.

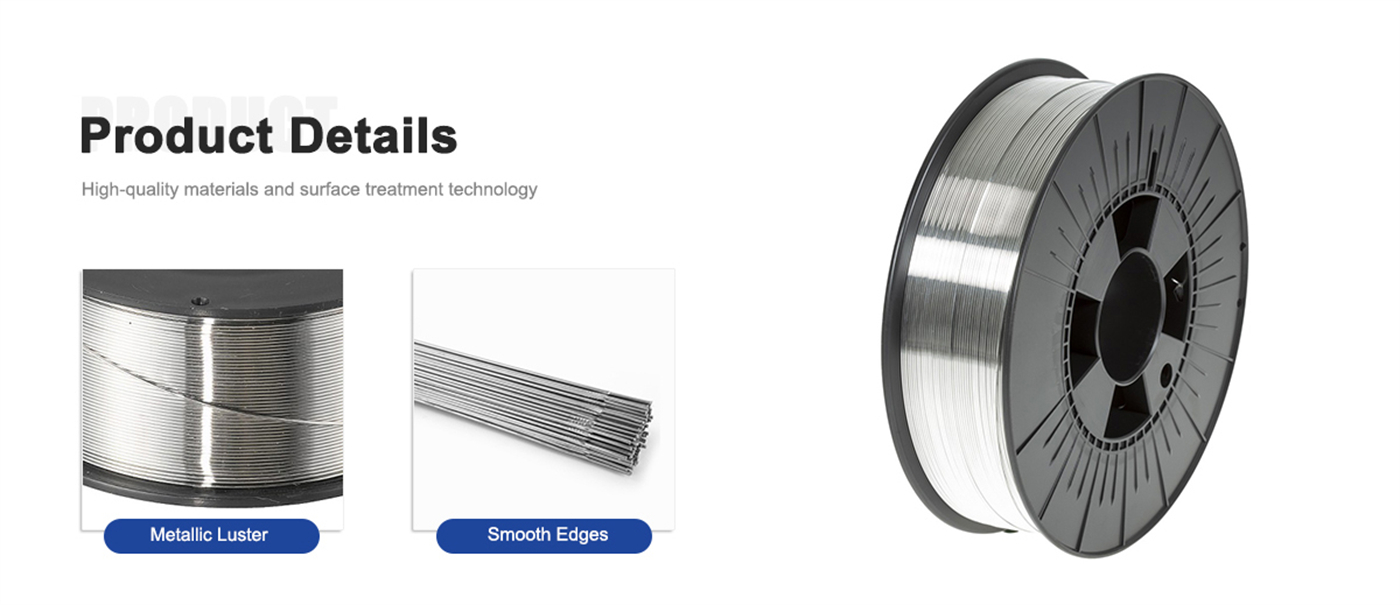

✅ Tilpassede størrelser og emballage – Tilgængelig i rulle, spiraler og tilpassede skårne længder.

✅ Hurtig & pålidelig global levering – Hurtig fragt til kunder over hele verden.

✅ Garanteret lagerplads – Altid på lager for store industrielle projekter.

Bestil Nickel Alloy ERNiCrMo-4 (C-276) Svejsningstråd I dag – Specielle rabatter tilgængelige!

Søger du premium svejsningstråd til fabrikspriser? Nyt vores rabatterede priser og storordenspriser! Kontakt os i dag for tilpassede ordrer og hurtig levering.

| Vare | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2,5-3,5 | 4 | 0.5-1.0 | 1 |

| F | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Ja | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | rest | rest | 0.25 |

| Ni | ≥58 | rest | rest | rest | ≥67 | 62-69 | 30-32 | ≥93 |

| CO | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

| AL | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1,5-3 | 0.5 | 2-3,5 |

| Kr | 20-23 | 14.5-16.5 | 22-24 | 28,5-31 | 18,0-22,0 | N/A | N/A | N/A |

| Nb+Ta | 3,5-4,15 | N/A | 1,8-2,5 | 0.01 | 2,0-3,0 | N/A | N/A | N/A |

| - Hvad? | 8,0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

| V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

| W | N/A | 3,0-4,5 | N/A | N/A | N/A | N/A | N/A | N/A |

| Rest | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

| Nickel og nickellegemevejsning tråd | |

| Produktmodel (AWS) | Anvendelse |

| ERNiCr-3 | Til svartering af 600, 601 og 800 legeringer selv, og til svartering af forskellige ståle mellem rostfrit stål og kulstofstål ERNiCrFe-7; Til svartering af Inconel-legeringer inden for ASTM B163, 166, 167 og 168 |

| ERNiCrFe-6 | Til svartering af stål og Inconel, svartering af stål og rostfrit stål samt nikkelbaserede legeringer |

| ERNiCrCoMo-1 | Forskelligs-svartering til svartering af nikkel-krom-kobolt-molybdænlegeringer og forskellige superlegeringer |

| ERNiCrMo-3 | Bruges til svartering af nikkel-legeringer, kulstofstål, rostfrit stål og lavlegeret stål, hovedsagelig brugt til svartering af 625, 601, 802 legering og svartering af 9% nikkel-legering |

| ERNi-CI | Industrielt ren nikkel til svartering af slående og grå gietjern |

| ERCuNi | Til svartering af 70/30, 80/20, 90/10 kobber-nikkel-legeringer |

| ERNiCu-7 | Til svartering af nikkel-kobber-legeringer B127, 163, 164 og 165 mv. |

| ERNi-1 | Til svejsning af ren nikkelcastinger og -formninger, såsom legemer inden for ASTM B160, 161, 162, 163 |

| ERNiFeMn-CI | Til svejsning af kuglegrænnejern, ductile jern, formbar cast iron og grå cast iron til sig selv eller til rostfrit stål, kulstofstål, lavlegmet stål og forskellige nikkellegemer |

| ERNiCrMo-4 | Til svejsning af nikkel-krom-molybdænlegemer selv, eller svejsning af nikkel-krom-molybdænlegemer og stål samt de fleste andre nikkelbaserede legemer |

| ERNiCrMo-11 | Anvendes til svejsning af nikkel-krom-molybdænlegemer selv, eller svejsning af nikkel-krom-molybdænlegemer og stål samt de fleste andre nikkelbaserede legemer, og kan også bruges til overfladesvejsning af nikkel-krom-molybdænlegemer og stålsvejsningsled |

| ERNiCrMo-13 | Til svejsning af lavkarbonnikkel-krom-molybdænlegemer |