Højtemperatur Incoloy 800H Blade – Direkte Levering fra Producent

Vi tilbyder fabriksdirekte priser og specielle rabatter for store bestillinger. Uanset om du har brug for små eller store mængder, leveres vores produkter hurtigt for at sikre en pålidelig forsyning til industriprojekter over hele verden.

- Oversigt

- Specifikation

- Ansøgninger

- Fælles spørgsmål

- Anbefalede produkter

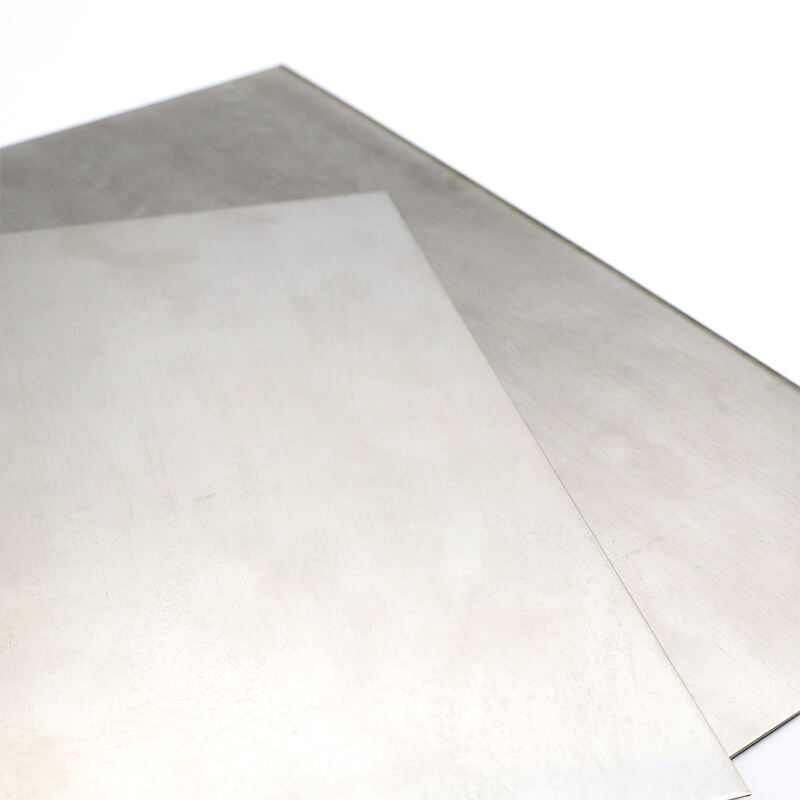

Introduktion til Incoloy 800H Plader

Incoloy 800H er en højydede nickel-jern-krom alloy, som er specielt udformet til at give fremragende styrke, fremragende korrosionsmodstand og fremragende stabilitet ved høj temperatur. Med forøget kulstofindhold i forhold til Incoloy 800 tilbyder denne alloy forbedret creep- og spændingsbrudmodstand, hvilket gør den ideel til højtemperaturs industrielle anvendelser.

Nøgletal for Incoloy 800H Plader

Fremragende højtemperaturs styrke: Vedligeholder mekanisk integritet under langvarig eksposition for ekstrem varme.

Overlegenhed ved oxidation og carburering: Kan klare strenge industrielle miljøer uden betydelig nedbrydning.

Forbedret krybe- og spændingsbrudsevne: Sikrer holdbarhed i kritiske anvendelser.

God skærmeldbarhed og formbarhed: Kan let formes og skærmeldes til tilpassede tekniske løsninger.

Anvendelser af Incoloy 800H plader

På grund af dets fremragende højtemperatursmodstand og mekaniske stabilitet bruges Incoloy 800H plader vidt omfattende i flere industrier, herunder:

Petrokemisk og raffinationsindustri: Bruges i reaktorer, procesrørledninger og højtemperaturvarmevekslere.

Energiproduktion: Anvendes i superheder- og genhederkomponenter i kraftværker.

Luftfart og ovnudstyr: Ideel til ovndele, varmebehandlingsskeletter og højtemperaturstrukturkomponenter.

Kemisk bearbejdning: Findes i trykfad, katalytiske reformere og varmevekslere, der udsættes for aggressive miljøer.

Kernereaktorindustri: Anvendt i dampgeneratører og reaktorkomponenter, der kræver fremragende varmebestandighed.

| Element | Procent (%) |

|---|---|

| Nickel (Ni) | 30,0-35,0 |

| Jern (Fe) | Balance |

| Krom (Cr) | 19.0-23.0 |

| Kulstof (C) | 0,05-0,10 |

| Aluminium (Al) | 0,15-0,60 |

| Titan (Ti) | 0,15-0,60 |

Produktionsprocessen for Incoloy 800H Blade

Vælgning af råmaterialer: Højkvalitets nickel, jern og kromlegemer bliver valgt til produktion.

Smeltning og raffination: Materialerne smeltes i en elektrisk bueovn og raffineres for renhed.

Varme- og koldevrivning: Blade vrives til den ønskede tykkelse og annealeres for forbedrede mekaniske egenskaber.

Varmetreatment: Løsningsannealing forbedrer højtemperaturstabilitet og korrosionsmodstand.

Overfladebehandling: Pickling, polering eller coatings sikrer optimal overfladequalitet.

Kvalitetskontrol og testing: Mekaniske, kemiske og dimensionelle tests udføres for at opfylde branches standarder.

Hvorfor vælge direkte levering fra producenten af Incoloy 800H blade?

Fabrikspris: Konkurrencedygtige priser for store mængder og grosordrer.

Garanteret kvalitet: Overholdelse af ASTM B409 og andre internationale standarder.

Tilpasning mulig: Blade i forskellige størrelser, tykkeder og overfladebehandlinger.

Pålidelig ydelse: Bevist holdbarhed i ekstreme industrielle miljøer.

Konklusion

Incoloy 800H plader tilbyder en fremragende kombination af højtemperatursstyrke, korrosionsresistens og mekanisk stabilitet, hvilket gør dem til en foretrukken valg for industrier, der kræver fremragende ydelse under ekstreme forhold. Med direkte levering fra producent kan virksomheder få adgang til højkvalitetsmaterialer til konkurrencedygtige priser, hvilket sikrer økonomisk effektivitet og pålidelighed i kravende anvendelser.

F.eks.

Hvor lang er leveringstiden?

Det afhænger af ordreens størrelse, 10-30 dage for små ordre. For store ordre tager det 60 dage.

Accepterer I OEM/ODM-produktion?

Ja! Vi accepterer OEM/ODM-produktion. Du kan sende os dine eksempler eller tegninger.

Hvordan kontrollerer I kvaliteten af jeres produkter? Opfylder de kemiske egenskaber af produkterne kvalitetsstandarderne?

Med en professionel kvalitetsteam, avanceret produktkvalitetsplanlægning, strikt gennemførelse og kontinuerlig forbedring, vil vi udstede produktkvalitetskundgørelse, herunder rapport om kemisk analyse.

Kan jeres firma levere detaljerede tekniske data og tegninger?

Ja, det kan du. Fortæl os venligst hvilke produkter og anvendelser du har brug for, og vi vil sende dig detaljerede tekniske data og tegninger til vurdering og bekræftelse.

Hvordan håndterer I forsalgs- og efftersalgservice?

Vi har et professionelt erhvervs team, der vil arbejde en-til-en for at beskytte dine produktbehov, og hvis du har nogen spørgsmål, kan han besvare dem for dig!

Kan jeg besøge jeres fabrik, før jeg placerer en ordre?

Ja, du er velkommen til at besøge vores fabrik. Vi glæder os over muligheden for at komme hinanden nærmere.

Hvor er jeres produktionsskov?

Vi fremstiller vores produkter i Jiangsu, Kina, og leverer dem fra Kina til jeres land så hurtigt som muligt, hvilket normalt afhænger af jeres produktkrav og mængde.

Kan du sende prøver?

Ja, det kan vi.