CuNi6 Alloy Rods: Ideal Solution for Electronics and Electrical Components

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

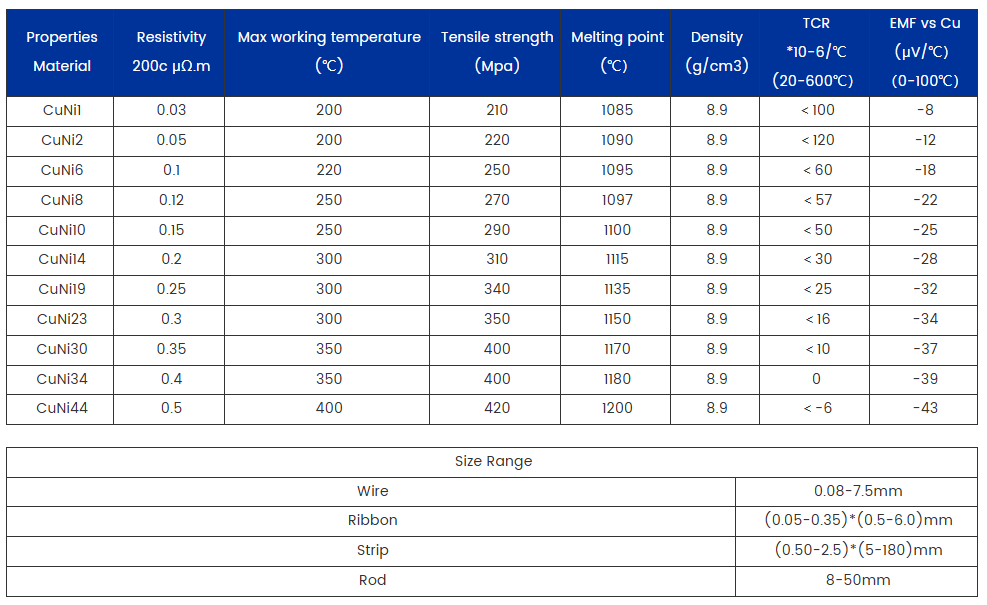

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

- Electrical Conductivity: CuNi6 alloy has excellent electrical conductivity, which makes it ideal for use in electrical and electronic components where efficient transmission of current is essential.

- Corrosion Resistance: The nickel content in CuNi6 enhances its resistance to corrosion, especially in harsh environments such as marine settings or areas with high humidity. This makes it suitable for use in components exposed to corrosive elements.

- Thermal Conductivity: The alloy offers good thermal conductivity, ensuring efficient heat dissipation in electronic components such as connectors, circuit boards, and heat exchangers.

- Mechanical Strength: CuNi6 has improved strength compared to pure copper, allowing it to maintain its integrity in high-stress applications while still retaining its excellent conductivity properties.

- Weldability and Machinability: CuNi6 is highly workable and can be easily welded or machined into various shapes, such as rods, bars, and wires, to suit specific design requirements in electronic and electrical applications.

-

Electrical Conductors and Connectors: CuNi6 alloy rods are widely used in the production of electrical conductors and connectors. The alloy’s excellent conductivity makes it ideal for components that need to efficiently transmit electrical current with minimal loss. CuNi6 is commonly used in electrical wiring, connectors, and contact points in devices that require high electrical conductivity, such as circuit boards, sensors, and power distribution systems.

-

Electronic Components: In the electronics industry, CuNi6 alloy rods are often used to manufacture components such as transistors, resistors, and capacitors. Its ability to resist oxidation while maintaining high conductivity makes it a reliable material for devices that operate under high power conditions. The alloy's durability also ensures long-lasting performance, even in components that are subjected to frequent use.

-

Heat Sinks and Heat Exchangers: CuNi6 is ideal for heat dissipation applications, making it a popular choice for manufacturing heat sinks and heat exchangers in electronics and electrical systems. The alloy’s excellent thermal conductivity ensures that heat generated by high-power electronic devices is efficiently transferred away from sensitive components, preventing overheating and ensuring optimal performance.

-

High-Frequency Components: CuNi6 alloy rods are used in high-frequency electronic applications where stable electrical properties are crucial. The alloy's resistance to corrosion and its high conductivity make it suitable for components such as antennas, RF (radio frequency) circuits, and other high-frequency equipment that require reliable and consistent performance.

-

Electrical Contacts and Switches: CuNi6 alloy is commonly used in the manufacturing of electrical contacts and switches due to its durability and ability to withstand frequent electrical connections and disconnections. The alloy’s resistance to wear and corrosion ensures that these components can perform reliably over long periods without degradation.

-

Battery Components: In rechargeable batteries, especially those used in electronics, CuNi6 alloy rods can be used in the manufacturing of battery terminals and connections. The alloy’s strength and conductivity help ensure that the batteries perform efficiently over time, even under demanding conditions.

-

Aerospace Electronics: CuNi6 alloy rods are used in aerospace electronics due to their high strength-to-weight ratio and resistance to environmental factors. Components such as wiring, connectors, and electrical systems in aircraft benefit from the durability and conductivity of CuNi6, ensuring reliable performance in challenging environments.

-

High Electrical Conductivity: The primary requirement for most electrical and electronic applications is high electrical conductivity. Users demand materials that efficiently transfer electrical current with minimal resistance. CuNi6 alloy, with its excellent conductivity, meets this need, ensuring optimal performance in applications ranging from consumer electronics to industrial power systems.

-

Corrosion Resistance: In many electronic and electrical applications, components are exposed to moisture, humidity, or even corrosive environments. CuNi6 alloy's resistance to corrosion ensures that electrical systems maintain their performance over time, even when exposed to challenging conditions such as marine environments or industrial settings.

-

Durability and Strength: Many electrical components, particularly those used in industrial and high-power applications, must withstand physical stress and wear. CuNi6’s strength and durability make it a perfect choice for components that need to maintain their integrity under mechanical load while still providing excellent conductivity.

-

Thermal Management: In the electronics and electrical industries, managing heat is a critical aspect of ensuring that devices operate efficiently and safely. CuNi6 alloy’s good thermal conductivity allows for effective heat dissipation, preventing overheating of electronic components and prolonging their lifespan.

-

Customization: Users often require materials that can be customized to specific sizes and shapes to meet the design and functionality requirements of particular applications. CuNi6 alloy rods are easily fabricated into a variety of forms, making them adaptable for a wide range of electronic and electrical components.

-

Cost-Effectiveness: Although CuNi6 may be slightly more expensive than pure copper, its superior mechanical properties, corrosion resistance, and long-term performance make it a cost-effective solution for industries that require durable and high-performance electrical components. The reduced need for maintenance and replacements makes CuNi6 a more economical choice in the long run.

CuNi6 alloy, consisting of 94% copper and 6% nickel, is a high-performance material renowned for its excellent electrical and thermal conductivity, as well as its superior resistance to corrosion and oxidation. This copper-nickel alloy is designed to deliver enhanced mechanical properties, making it suitable for a wide range of applications, particularly in the electronics and electrical components industry. CuNi6 alloy rods are known for their ability to maintain high conductivity while exhibiting good strength and durability, even under challenging operational conditions.

The addition of nickel to the copper matrix improves the alloy's mechanical properties, particularly its resistance to wear and tear, making it ideal for applications where both conductivity and strength are required. This combination of attributes makes CuNi6 a versatile material, suitable for high-performance electrical components in various industries.

Key Properties of CuNi6 Alloy

Applications of CuNi6 Alloy Rods

User Needs and Demands

The growing demand for CuNi6 alloy rods in electronics and electrical components is driven by several key user needs:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.