CuNi14 Alloy Sheets for Superior Resistance in Sea Water and Offshore Structures

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

- Corrosion Resistance: The primary feature of CuNi14 alloy is its outstanding resistance to corrosion, particularly in seawater. Its high nickel content significantly improves its ability to resist oxidation, pitting, and erosion in marine environments, making it ideal for long-term use in offshore structures and marine equipment.

- Strength and Durability: CuNi14 offers high tensile strength, which allows it to withstand mechanical stress and strain, particularly in offshore environments where materials are exposed to constant physical pressure and turbulence. Its durability ensures the longevity of components exposed to rough sea conditions.

- Malleability and Fabrication: CuNi14 alloy is highly malleable and can be easily fabricated into sheets, plates, and other shapes that are required for marine and offshore structures. This property makes it ideal for custom-made parts that need to fit into complex designs and withstand harsh environmental conditions.

- Thermal and Electrical Conductivity: While CuNi14 is not as conductive as pure copper, it still offers adequate thermal and electrical conductivity, which is beneficial in some marine applications where heat dissipation and electrical performance are important.

- Resistance to Biofouling: CuNi14 also resists biofouling, which is the accumulation of microorganisms, algae, and other organisms on submerged surfaces. This characteristic helps maintain the performance and appearance of offshore structures, reducing maintenance requirements.

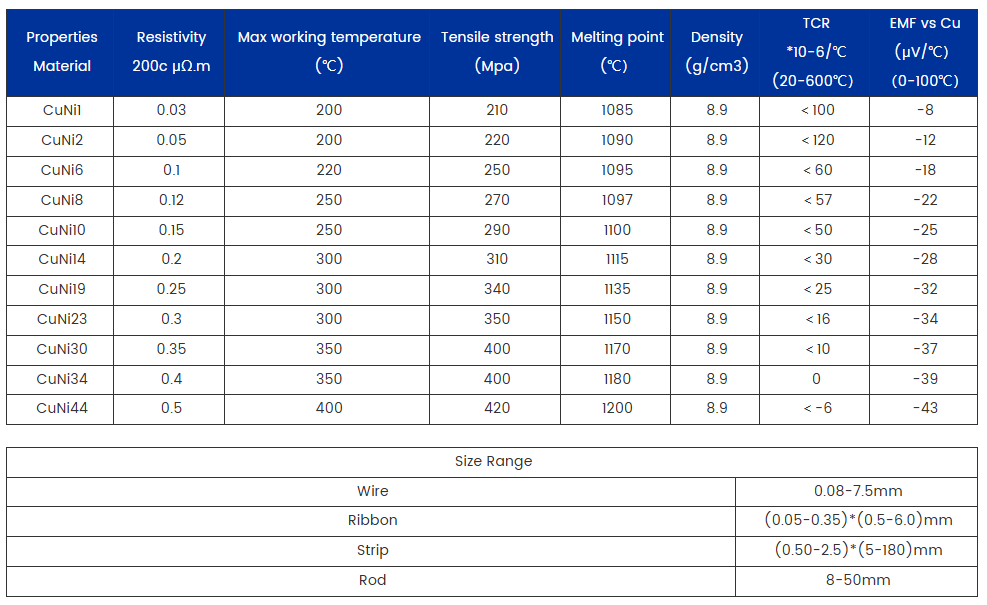

CuNi14 alloy, composed of 86% copper and 14% nickel, is a high-performance material known for its exceptional resistance to corrosion, especially in harsh marine environments. The alloy’s 14% nickel content enhances its resistance to seawater corrosion, making it an ideal material for offshore structures, shipbuilding, and marine applications. CuNi14 is often used in environments that require materials to withstand constant exposure to saltwater, high humidity, and other corrosive elements.

In addition to its corrosion resistance, CuNi14 offers excellent mechanical properties, including high tensile strength and durability, ensuring that components made from this alloy can endure harsh physical conditions. It is also highly malleable, making it suitable for a wide variety of fabrication processes, including the production of sheets, plates, and other complex shapes needed for offshore and marine applications.

Key Properties of CuNi14 Alloy

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.