CuNi10 Alloy Tubes for Enhanced Performance in Medical Devices

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

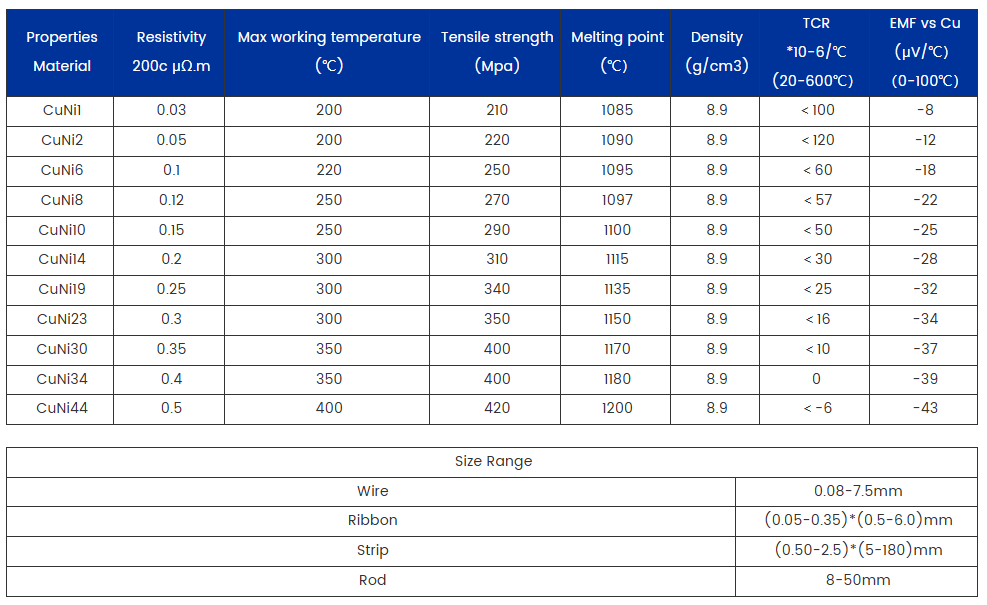

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

- Corrosion Resistance: One of the standout features of CuNi10 is its exceptional resistance to corrosion, particularly in harsh environments. This makes it ideal for use in medical devices that are often exposed to bodily fluids, sterilization processes, and corrosive agents.

- Strength and Durability: CuNi10 offers excellent mechanical properties, including high tensile strength and resistance to wear, ensuring the longevity and reliability of medical devices that are subjected to physical stress and regular use.

- Biocompatibility: The alloy is biocompatible, meaning it does not cause adverse reactions when in contact with body tissues. This makes CuNi10 an ideal material for implantable medical devices such as stents, catheters, and other devices that come into direct contact with the human body.

- Thermal and Electrical Conductivity: CuNi10 offers good thermal and electrical conductivity, which is crucial for devices that require efficient heat dissipation and electrical performance, such as sensors, electrodes, and diagnostic instruments.

- Malleability and Fabrication: CuNi10 alloy is highly malleable, making it easy to form into thin tubes, wires, and other shapes that are commonly required for medical devices. Its ease of fabrication ensures that it can be tailored to meet the specific requirements of different medical applications.

-

Implantable Medical Devices: CuNi10 alloy tubes are frequently used in the production of implantable medical devices, such as stents, pacemakers, and catheters. These devices require materials that are both biocompatible and durable, with the ability to withstand the physical stress they undergo inside the body. CuNi10’s combination of strength, corrosion resistance, and biocompatibility makes it a perfect choice for these applications.

-

Diagnostic Instruments: In diagnostic devices, CuNi10 alloy tubes are used in sensors, electrodes, and other components that need to perform under demanding conditions. The alloy’s excellent electrical conductivity ensures accurate and reliable readings from devices such as blood glucose monitors, ECG machines, and other medical instruments that rely on precise electrical signals.

-

Medical Tubing for Fluid Transport: CuNi10 alloy tubes are used in medical tubing applications where fluids need to be transported safely and reliably. The alloy's corrosion resistance ensures that it maintains its integrity when exposed to medical fluids, while its strength ensures that it can withstand pressure without breaking or deforming. It is particularly useful in applications such as intravenous (IV) tubing, dialysis tubing, and blood transfusion lines.

-

Endoscopic Devices: Endoscopic devices, which are used for minimally invasive surgeries, often require flexible, durable, and corrosion-resistant tubing. CuNi10 alloy tubes meet these requirements, providing flexibility and strength while resisting corrosion from bodily fluids and sterilization processes.

-

Needles and Syringes: CuNi10 alloy tubes are also used in the manufacture of needles and syringes. These devices require a material that can be formed into fine, sharp points while maintaining its strength and corrosion resistance. CuNi10's malleability makes it an ideal material for producing high-quality needles and other medical injection devices.

-

Medical Electrical Connectors: CuNi10 tubes are also used in the construction of electrical connectors for medical devices, including those used in diagnostic tools and surgical equipment. The alloy's high electrical conductivity and strength ensure that these connectors maintain a reliable and efficient electrical connection even under extreme conditions.

-

Wound Dressings and Surgical Implants: CuNi10’s corrosion resistance also makes it a suitable choice for medical implants and wound dressings that require long-term contact with the body. The material ensures that the implants do not degrade or corrode in the body, making it a trusted material in these applications.

-

Biocompatibility: One of the most crucial considerations in medical devices is biocompatibility. Users require materials that will not cause adverse reactions when in contact with the human body. CuNi10's biocompatibility ensures that devices made from it are safe for implantable and in-body applications.

-

Corrosion Resistance: Medical devices, particularly those used in implantable applications or in contact with bodily fluids, need to resist corrosion over extended periods. CuNi10’s exceptional corrosion resistance ensures that devices maintain their integrity and functionality, even after prolonged exposure to challenging environments.

-

Mechanical Strength: Medical devices must withstand physical stress and forces during use. CuNi10’s high tensile strength and durability ensure that tubes, wires, and other components remain functional and reliable even under pressure, bending, and other mechanical stresses.

-

Precision and Malleability: Users require materials that can be precisely manufactured to meet the intricate and specific designs required in medical devices. CuNi10’s malleability allows it to be easily formed into thin tubes and other shapes that are necessary for a wide range of medical applications.

-

Thermal and Electrical Performance: Many medical devices rely on efficient heat dissipation or the conduction of electrical signals to function properly. CuNi10’s good thermal and electrical conductivity ensures that devices, such as sensors and diagnostic tools, perform reliably and accurately.

-

Long-Term Reliability: The longevity and performance of medical devices are paramount, especially in implantable applications. CuNi10’s durability ensures that it can withstand years of use, making it a cost-effective material for long-term medical applications.

-

Cost-Effectiveness: While CuNi10 may be more expensive than some other materials, its long-term reliability, biocompatibility, and corrosion resistance make it a worthwhile investment for the medical industry. Users demand materials that offer value by reducing the need for frequent replacements or repairs.

CuNi10 alloy, comprising 90% copper and 10% nickel, is a highly durable material known for its excellent corrosion resistance, high strength, and superior performance in demanding applications. The combination of copper and nickel enhances the alloy's ability to resist oxidation, making it especially suitable for environments where corrosion is a significant concern. CuNi10 is commonly used in industries where both mechanical strength and excellent conductivity are required.

In the context of medical devices, CuNi10 alloy offers the added advantage of being biocompatible, making it safe for use in medical applications. Its impressive strength, combined with good thermal and electrical conductivity, provides optimal performance in a variety of medical technologies, especially those used for diagnostic purposes, medical instrumentation, and implantable devices. CuNi10 alloy tubes, in particular, provide a reliable, long-lasting solution to the challenges faced by the medical industry.

Key Properties of CuNi10 Alloy

Applications of CuNi10 Alloy Tubes in Medical Devices

User Needs and Demands

The growing demand for CuNi10 alloy tubes in the medical device industry is driven by several key factors. Users in the medical sector require materials that meet stringent standards for biocompatibility, performance, and reliability. Below are some of the key user needs and demands:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.