CuNi1 Alloy Wire – Ideal for Low-Temperature Electrical Heating Elements

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Applications

- FAQs

- Recommended Products

1. Material Introduction

CuNi1 alloy wire is composed of 99% copper and 1% nickel. It is a copper-nickel alloy that offers excellent conductivity, moderate corrosion resistance, and a stable resistive performance, making it ideal for low-temperature electrical heating elements. The low nickel content of CuNi1 makes it cost-effective, while still providing sufficient resistance stability and durability in various applications. Although it is not suited for extremely high-temperature environments, CuNi1 alloy wire excels in low-temperature heating applications.

Key characteristics of CuNi1 alloy wire include:

Resistivity: It provides stable resistive properties, ensuring even heat generation.

Good Conductivity: The high copper content ensures excellent electrical conductivity, making it suitable for low-power heating applications.

Corrosion Resistance: CuNi1 has moderate corrosion resistance compared to pure copper, making it suitable for light corrosion environments.

Mechanical Strength: While CuNi1 alloy wire has moderate mechanical strength, it performs reliably under light load conditions.

2. Applications

CuNi1 alloy wire is widely used in low-temperature electrical heating elements, particularly in applications where high-temperature resistance is not a primary concern. Here are some typical applications:

2.1 Low-Temperature Electrical Heating Elements

CuNi1 alloy wire is commonly used in low-temperature heating elements, such as:

Home Appliances: It is used in heating elements for products like electric kettles, ovens, and water heaters. CuNi1 wire provides stable resistance and meets the needs of low-temperature heating systems in household appliances.

Laboratory Equipment: Many laboratory heating devices require precise temperature control in a lower temperature range. CuNi1 alloy wire, with its stable resistivity, is commonly used in these types of heating elements.

2.2 Electronic Heating Elements

In electronic heating devices such as heating pads, electric blankets, and low-power heating systems, CuNi1 alloy wire provides an efficient and cost-effective heating solution, thanks to its stable resistivity and low nickel content.

2.3 Low-Power Heating Systems

For applications requiring low-power heating systems, CuNi1 alloy wire is well-suited due to its appropriate resistivity. It is commonly used in lightweight heating systems where temperature control is important but not extreme.

2.4 Temperature Controllers

CuNi1 alloy wire is also used in temperature controllers, especially for applications in the lower temperature range. It helps to maintain stable and accurate temperature readings in systems where precise temperature control is required.

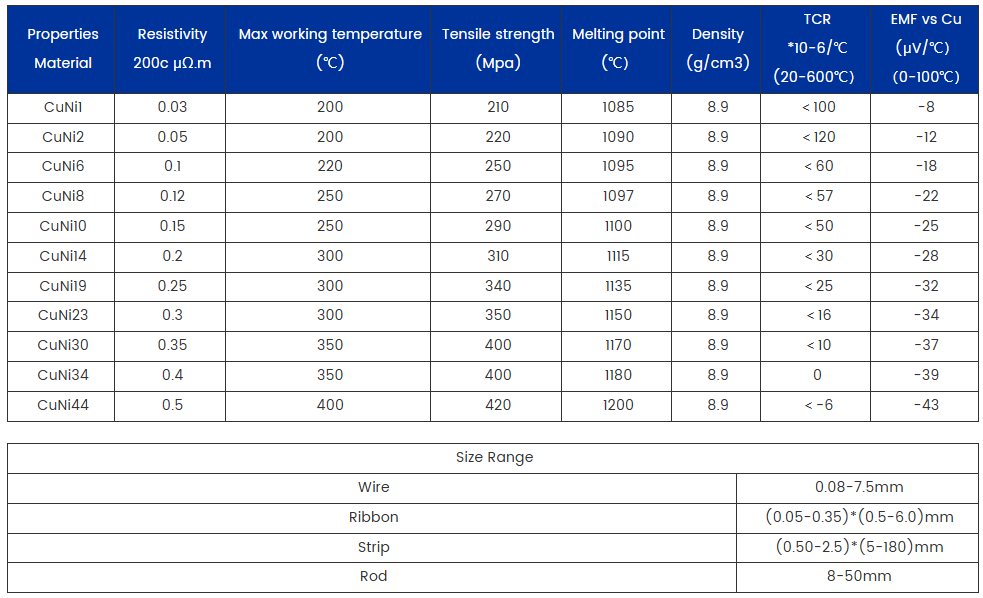

3. Grades and Characteristics

CuNi1 alloy wire is designated by its composition, containing 1% nickel and 99% copper. The properties of this alloy are influenced by its low nickel content:

Lower Cost: The relatively low nickel content makes CuNi1 alloy wire more economical compared to higher nickel alloys, making it suitable for low-cost heating applications.

Stable Resistance: Despite having a lower nickel content, CuNi1 maintains stable resistance, making it ideal for low-temperature electrical heating elements.

Environmental Suitability: CuNi1 alloy wire has moderate corrosion resistance, making it suitable for applications in environments with mild corrosion exposure.

4. Manufacturing Process

The manufacturing process for CuNi1 alloy wire involves several key stages:

4.1 Alloy Preparation and Melting

Copper and nickel are melted together to create the alloy, ensuring uniformity of the composition. Strict control during the melting process ensures that CuNi1 alloy wire exhibits consistent resistive properties and overall performance.

4.2 Wire Drawing

After melting, the alloy is processed into wire form through a drawing process. The wire is drawn through multiple molds to achieve different diameters. The temperature and pressure during the drawing process are carefully controlled to ensure the consistency of the wire’s properties.

4.3 Annealing

The wire undergoes an annealing process to relieve stress from the drawing process and improve the material's ductility. This step helps enhance the mechanical properties and reduce brittleness in the alloy.

4.4 Surface Treatment

To improve corrosion resistance and oxidation resistance, the CuNi1 alloy wire is often treated with surface coatings, such as oxidation or other protective coatings. These treatments ensure the wire remains durable in humid or mildly corrosive environments.

4.5 Quality Control and Testing

The manufacturing process includes rigorous quality control, including testing the wire’s diameter, resistivity, conductivity, and mechanical strength. Every batch of CuNi1 alloy wire is subjected to performance testing to ensure its reliability and suitability for the intended applications.

5. User Requirements

When selecting CuNi1 alloy wire, users typically have the following requirements:

5.1 Stable Resistivity

Users require CuNi1 alloy wire to provide stable resistance over time, particularly in heating applications. This stability ensures that the heating element functions efficiently without excessive power loss.

5.2 Temperature Performance

While CuNi1 alloy wire is used for low-temperature applications, users expect it to perform reliably within a temperature range, typically not exceeding 400°C. Its ability to maintain stability at these temperatures is critical for ensuring consistent heating.

5.3 Cost-Effectiveness

CuNi1 alloy wire is selected by users who are looking for a cost-effective solution for low-power heating elements. Its lower nickel content reduces production costs, making it an attractive option for large-scale manufacturing and applications requiring lower overall costs.

5.4 Mechanical Properties

Users expect the alloy wire to have sufficient mechanical strength to withstand moderate tension and pressure while retaining flexibility and ease of handling.

5.5 Corrosion Resistance

Although CuNi1 alloy wire’s corrosion resistance is moderate, it is generally suitable for environments where exposure to corrosion is minimal. Users typically select CuNi1 for applications where humidity or mild corrosive conditions are present, without requiring the high-level protection of alloys with more nickel content.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.