Pásy z Hastelloidu C-22 – průmyslová kvalita slitin s maximální odolností proti korozi

Nabízíme ceny přímo z továrny a speciální slevy za velké objednávky. Ať už potřebujete malé nebo velké množství, naše produkty jsou dodávány rychle, aby se zajistila spolehlivá dodávka pro průmyslové projekty po celém světě.

- Přehled

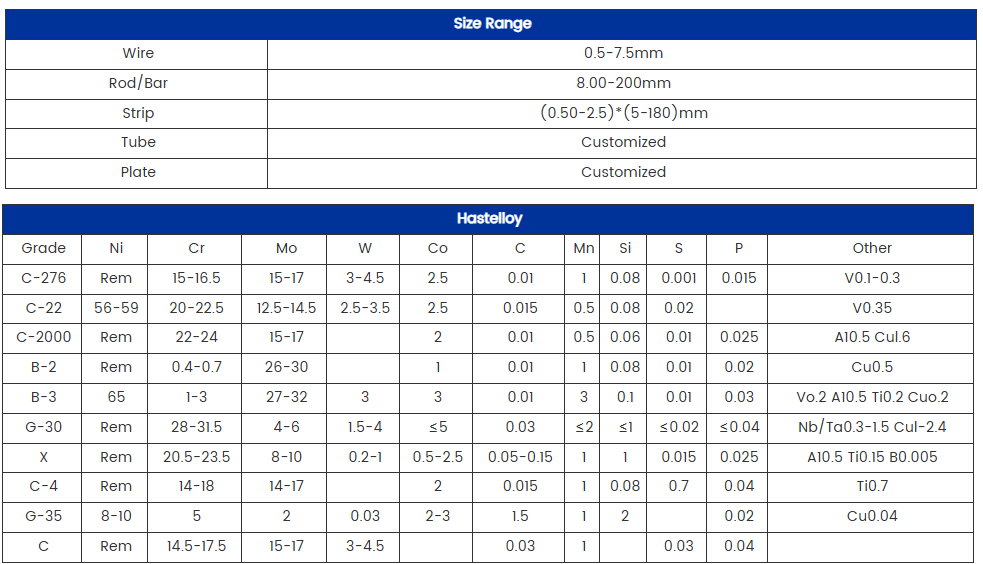

- Specifikace

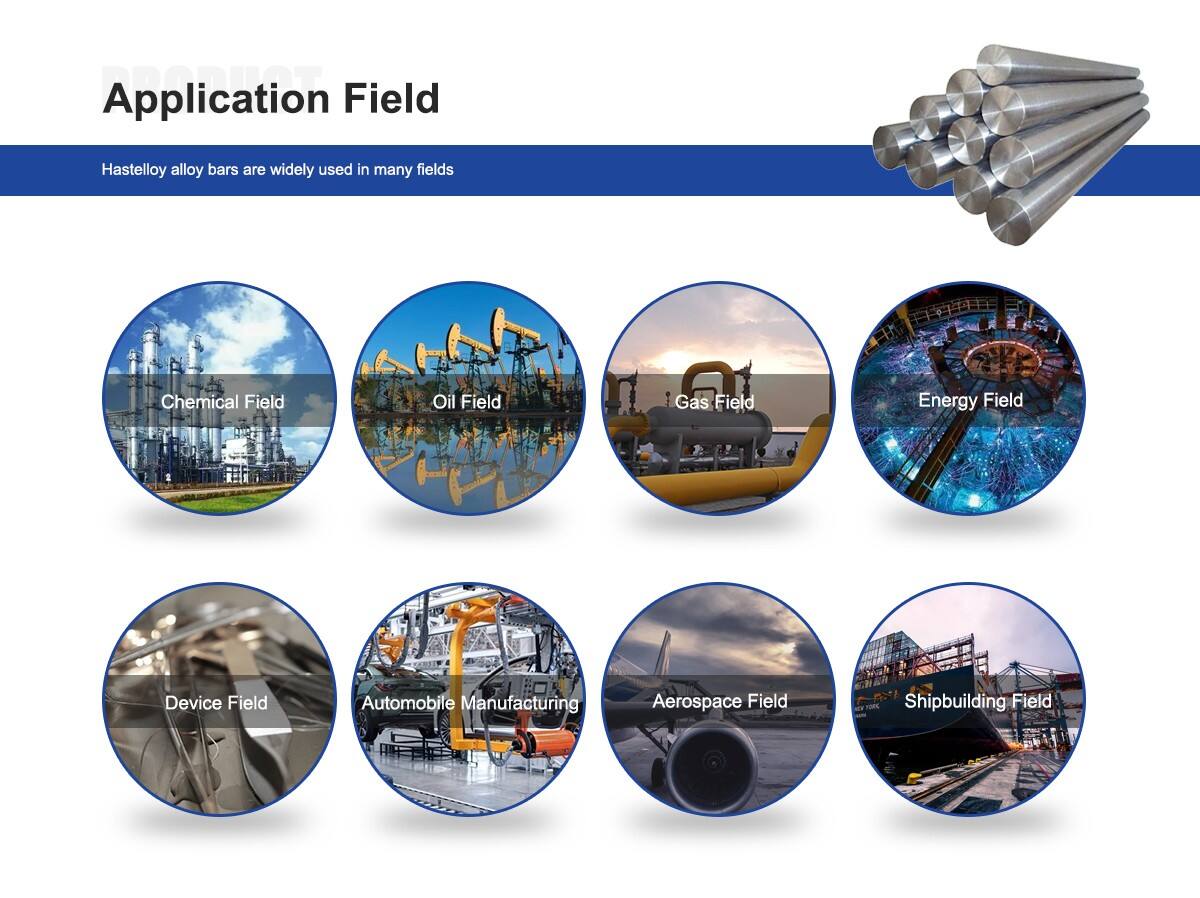

- Aplikace

- Nejčastější dotazy

- Doporučené produkty

-

Vynikající odolnost proti korozi: Vysoká odolnost proti pittingu, štěrbinové korozi a korozi napěťové v oxidujících i redukčních prostředích.

-

Vysoká tepelná stabilita: Udržuje mechanickou integrity i při vysokých teplotách.

-

Výborná tvaritelnost: Snadno se formuje, svařuje a strojí pro různé průmyslové použití.

-

Chemická inertnost: Dobře funguje v tvrdých chemických podmínkách, včetně zpracování kyselin.

-

Chemická procesní průmyslová výroba: Používá se v reaktorech, výměníčích tepla a potrubních systémech pro zacházení s agresivními chemikáliemi.

-

Letecký a námořní inženýrství: Ideální pro součásti vystavené vysoké vlhkosti, solným prostředím a extrémním teplotám.

-

Farmaceutický a potravinářský průmysl: Používá se v sterilizačním zařízení a procesních nádržích, kde jsou důležité hygiena a odolnost proti korozi.

-

Systémy na očištění flue gas: Používá se v zařízeních na kontrolu znečišťování pro odolnost vůči vysoce kyselým plynům a tvrdým podmínkám.

-

Elektrárny: Používány v geotermálních a jaderných elektrárnách, kde extrémní podmínky vyžadují vynikající výkon materiálu.

-

UNS číslo: N06022

-

Normy ASTM: ASTM B575 (Listy a pásy), ASTM B622 (Bezzávodové trubky), ASTM B619/B626 (Svářené trubky a roury)

-

EN/DIN ekvivalent: 2.4602

-

Tavení a slitování: Surové materiály jsou taveny pomocí vakuum indukčního tavení (VIM) nebo elektrodrahové pece (EAF) pro dosažení požadovaného složení.

-

Horké a studené valení: slitina je zpracována ve valících kotcích pro vytvoření pásů různých tloušťek.

-

Vyhlazování: Tepelné zpracování je aplikováno pro zvýšení pružnosti a odolnosti proti korozi.

-

Obrábění povrchu: Provádí se kyselinování a pasivace pro udržení čistého, koroze odolného povrchu.

-

Kontrola kvality: Mechanické a chemické testy, včetně kontrol tensilní síly, tvrdosti a odolnosti proti korozi, jsou prováděny pro zajistění dodržování průmyslových standardů.

-

Rozmanitost tloušťky a šířky: Přesný řez pro konkrétní průmyslové aplikace.

-

Možnosti dokončení povrchu: Dostupné ve šlichtěné, štětcové nebo tovární dokončení.

-

Tvarovatelnost a spojovatelnost: Zajištění snadného tvarování do složitých tvarů a konstrukcí.

-

Soulad s předpisy: Splňování certifikací ASTM, ASME a dalších průmyslových standardů pro zaručenou bezpečnost a výkon.

Úvod

Hastelloy C-22 je niklová super slitina známá svou vynikající odolností proti korozi, díky čemuž je oblíbená v extrémně agresivních prostředích. Při zpracování do pásů nabývá tato slitina univerzálnosti a spolehlivosti pro různé průmyslové aplikace vyžadující vysokou sílu a trvanlivost.

Složení materiálu a vlastnosti

Hastelloy C-22 se hlavně skládá z niklu, s významnými příměsí chromu, molibdenu a železa. Obsahuje také wolfrám a kobalt, které dále zvyšují jeho odolnost proti korozi. Klíčové vlastnosti pásů Hastelloy C-22 zahrnují:

Aplikace plátků Hastelloy C-22

Unikátní vlastnosti plátků Hastelloy C-22 je dělají vhodnými pro mnoho aplikací v různých odvětvích:

Typy a normy

Hastelloy C-22 je dostupný v různých mezinárodních normách a specifikacích, což zajistí jeho vhodnost pro globální průmyslové aplikace. Některé klíčové označení zahrnují:

Výrobní proces

Výroba pásků z Hastelloy C-22 probíhá ve více fázích, aby byla dosažena optimální výkonnosti:

Požadavky uživatele a přizpůsobení

Průmysly využívající pásy Hastelloy C-22 často vyžadují upravené specifikace, aby vyhověly jejich provozním potřebám. Běžné možnosti přizpůsobení zahrnují:

Často kladené otázky:

Jak dlouho to bude trvat?

Závisí to na množství objednávky, 10-30 dní pro malé objednávky. Pro velké objednávky to trvá 60 dní.

Přijímáte výrobu pod značkou OEM/ODM?

Ano! Přijímáme výrobu pod značkou OEM/ODM. Můžete nám poslat své vzorky nebo nákresy.

Jak řídíte kvalitu vašich produktů? Splňují chemické vlastnosti produktů kvalitní normy?

S profesionálním týmem pro kvalitu, pokročilým plánováním kvality produktu, přísným prováděním a nepřetržitou vylepšováním vydateme certifikát o prohlídce kvality produktu, včetně analytického chemického zprávy.

Může vaše firma poskytnout podrobná technická data a nákresy?

Ano, můžete. Prosím dejte nám vědět, jaké produkty a aplikace potřebujete, a pošleme vám podrobná technická data a nákresy pro vaši hodnocení a potvrzení.

Jak zpracováváte predprodejní a pozdější servisní služby?

Máme profesionální obchodní tým, který bude pracovat jednotlivě s vámi na ochranu vašich potřeb produktů a pokud máte jakékoliv otázky, může na ně odpovědět!

Můžu navštívit vaši továrnu před tím, než vložím objednávku?

Ano, jste vítáni k návštěvě naší továrny. Rádi máme možnost si navzájem přijít blíž.

Kde je vaše výrobní závod?

Vyrábíme naše produkty v provincii Jiangsu, Čína, a odesíláme je z Číny do vaší země co nejdříve, což obvykle závisí na požadavcích na produktech a množství.

Můžete poslat vzorky?

Ano, umíme.