Corrosion-Resistant Nimonic 90 Spring Wire for Gas Turbines and Power Plants

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

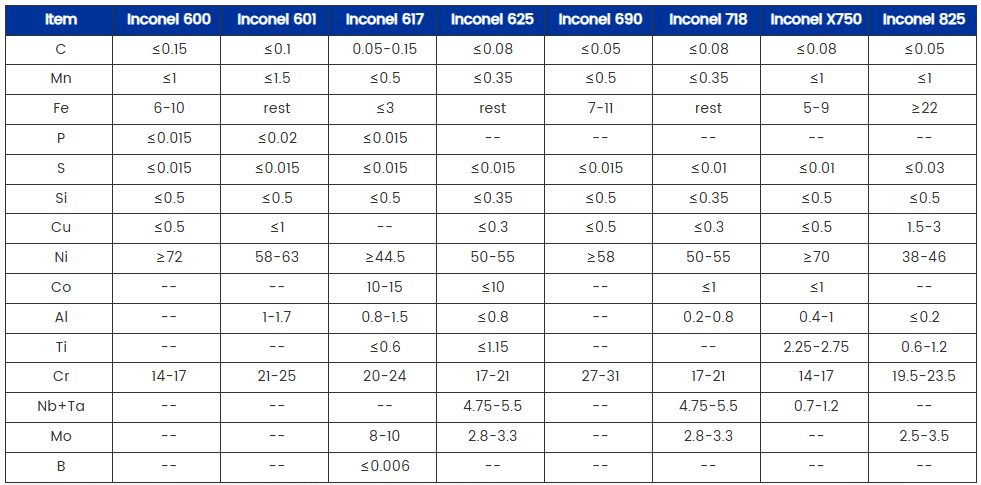

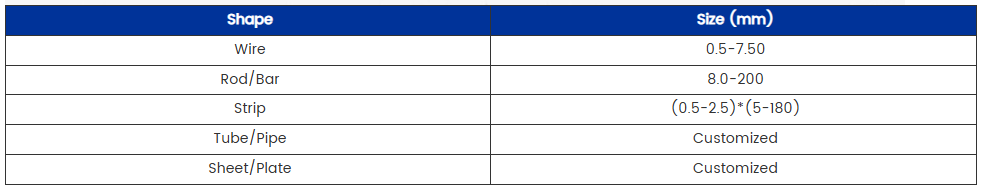

- Specification

- Applications

- FAQs

- Recommended Products

-

High-Temperature Oxidation Resistance: Forms a stable chromium oxide layer protecting up to 800°C (1472°F)

-

Hot Corrosion Resistance: Withstands sulfidation and other forms of high-temperature corrosion

-

Chloride Stress Corrosion Cracking Resistance: Maintains integrity in marine and industrial environments

-

Carburization Resistance: Protects against carbon penetration in hydrocarbon-rich atmospheres

-

Phase Stability: Resists harmful sigma phase formation during long-term exposure to high temperatures

-

Combustion chamber springs requiring both high strength and corrosion resistance

-

Turbine blade retainers exposed to hot gas path corrosion

-

Fuel system components resisting sulfur-containing fuels

-

Steam turbine valve springs in supercritical power plants

-

Heat exchanger components for combined cycle plants

-

Boiler feedwater system springs in high-pressure environments

-

Compressor discharge seals in corrosive industrial atmospheres

-

Exhaust system components resisting acid dew point corrosion

-

Recuperator springs for heat recovery systems

-

Increasing turbine inlet temperatures demanding better corrosion-resistant materials

-

Adoption of supercritical CO₂ cycles requiring advanced alloys

-

Flexible operation of gas turbines causing more thermal cycling stress

-

Need for materials resistant to more frequent start-stop corrosion

-

Growing use of alternative fuels (hydrogen blends, biofuels) requiring corrosion-resistant alloys

-

Operation with lower-grade fuels containing more corrosive contaminants

-

Industry push for longer inspection cycles requiring more durable materials

-

Need for components that maintain integrity after years of service

-

Increased use of additive manufacturing for complex corrosion-resistant components

-

Development of specialized wire forms for automated spring production

In the demanding environments of gas turbines and power generation systems, where components face extreme temperatures, mechanical stresses, and corrosive media, Nimonic 90 has established itself as a premier nickel-chromium-cobalt superalloy. Specifically engineered for corrosion resistance in high-temperature applications, Nimonic 90 spring wire delivers unmatched performance in critical power generation components. This article examines the alloy's corrosion-resistant properties, its specialized applications in energy systems, and the evolving industry trends driving its adoption.

Superior Corrosion Resistance Properties

Nimonic 90 offers exceptional protection against various forms of degradation in harsh operating environments:

Critical Applications in Energy Systems

1. Gas Turbine Components

2. Power Generation Systems

3. Industrial Gas Turbines

Industry Trends Driving Demand

1. Higher Efficiency Power Generation

2. Renewable Energy Integration

3. Fuel Flexibility Requirements

4. Extended Maintenance Intervals

5. Advanced Manufacturing Adoption

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.