Corrosion-Resistant CuNi2 Alloy Bars for Chemical Industry and Heat Exchangers

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- Off-the-shelf supply

- FAQs

- Recommended Products

- Corrosion Resistance: CuNi2 alloy offers exceptional resistance to corrosion in a variety of chemical environments, including acids, alkalis, and seawater. Its ability to withstand chemical attacks makes it ideal for use in aggressive industrial processes.

- Strength and Durability: The alloy retains its strength even in high-temperature conditions, providing long-term reliability and minimizing the need for frequent replacements.

- Heat Resistance: CuNi2 has excellent thermal conductivity and can perform well in heat exchangers and other systems that require efficient heat transfer under high temperatures.

- Fabrication Ease: CuNi2 is easy to process, weld, and fabricate into complex shapes and forms, allowing manufacturers to create custom components that meet specific industry needs.

- Biocompatibility: The alloy’s biocompatibility also makes it suitable for applications that come in contact with sensitive environments, such as medical or food-grade chemical systems.

-

Chemical Industry: CuNi2 alloy is widely used in the chemical industry for constructing equipment such as reactors, pipes, valves, and heat exchangers. The alloy’s resistance to aggressive chemicals, acids, and alkalis makes it an ideal choice for equipment that is exposed to these substances during industrial processes. CuNi2 bars are commonly used to build components that require long-term durability and reliability, even when exposed to harsh conditions.

-

Heat Exchangers: One of the primary applications of CuNi2 alloy bars is in heat exchangers. In this context, the alloy is used for both cooling and heating applications where the materials come into contact with hot fluids, gases, and aggressive chemicals. The corrosion resistance and thermal conductivity of CuNi2 make it an excellent choice for the construction of heat exchangers in chemical plants, power generation facilities, and industrial cooling systems.

-

Marine Chemical Processing: CuNi2 is used in marine chemical processing plants for handling seawater, brine, and other harsh chemicals. It is particularly useful for equipment like desalination plant components, pumps, and piping systems, as it resists corrosion from both the chemical nature of seawater and the mechanical stress of continuous operation.

-

Oil & Gas Industry: In the oil and gas sector, CuNi2 alloy bars are used for making components that must endure exposure to harsh chemicals, high temperatures, and mechanical stresses. Equipment like separators, heat exchangers, and offshore drilling rigs use CuNi2 alloy for its durability and resistance to corrosion in both acidic and saline environments.

-

Power Generation: In power plants, CuNi2 alloy is utilized for constructing cooling systems and heat exchangers. The material’s superior resistance to corrosion and its ability to transfer heat efficiently make it ideal for managing high-temperature environments, such as those found in steam power generation plants.

-

Desalination Plants: The desalination industry, which deals with the extraction of fresh water from seawater, also benefits from the use of CuNi2 alloy bars. The alloy is resistant to the effects of seawater and is commonly used in the construction of heat exchangers and other parts of desalination systems.

-

Corrosion Resistance: One of the primary reasons that the chemical industry and heat exchangers rely on CuNi2 alloy bars is their superior resistance to corrosion. Chemical environments often contain highly aggressive substances that can quickly degrade unprotected metals. CuNi2’s resistance to pitting, stress corrosion cracking, and general corrosion makes it an ideal choice for these applications, ensuring equipment longevity and reducing maintenance costs.

-

High-Temperature Performance: Many processes in the chemical industry and heat exchangers involve high temperatures, where materials are exposed to both thermal and chemical stress. CuNi2 alloy offers excellent thermal stability and high strength at elevated temperatures, making it a preferred material for components that need to function reliably under heat and pressure.

-

Durability and Longevity: In industries where equipment replacement is costly and downtime can affect production, the demand for durable materials is high. CuNi2 alloy bars meet this need by offering superior mechanical properties that help extend the life of equipment. The alloy’s resistance to corrosion and high temperatures ensures that components last longer, even under continuous exposure to aggressive chemicals and extreme conditions.

-

Custom Fabrication: In many applications, components need to be customized to fit specific designs and functionality requirements. CuNi2 alloy’s ease of fabrication and welding allows users to create customized shapes, sizes, and designs for a wide range of applications, from pipes and fittings to complex heat exchanger systems.

-

Cost-Effectiveness: While CuNi2 may have a higher upfront cost compared to other materials, its durability and long lifespan make it a cost-effective option in the long run. Users prioritize materials that will reduce maintenance and replacement costs, and CuNi2’s longevity ensures that components made from it will perform for years without needing frequent replacements.

-

Environmental Considerations: As industries focus on sustainability, materials that minimize environmental impact are in high demand. CuNi2 is an environmentally friendly alloy, resistant to corrosion and biofouling, which can reduce the need for toxic chemicals or treatments. This makes it a sustainable choice for chemical and marine applications, where reducing chemical exposure and environmental degradation is essential.

CuNi2 alloy is a copper-nickel alloy containing 98% copper and 2% nickel. This combination results in an alloy that offers outstanding corrosion resistance, especially in harsh environments such as chemical processing and heat exchange applications. CuNi2 alloy bars are known for their ability to withstand the corrosive effects of various chemicals, making them ideal for use in industries that deal with aggressive substances. The alloy’s nickel content enhances its strength and oxidation resistance, ensuring long-lasting performance even in extreme conditions.

One of the most notable properties of CuNi2 is its resistance to stress corrosion cracking, pitting, and crevice corrosion, which are common issues when metals are exposed to aggressive chemicals or high-temperature environments. Additionally, CuNi2 maintains good mechanical properties and is relatively easy to fabricate and weld, which is crucial for industries that require intricate component designs. Its resistance to corrosion makes it a reliable choice for applications where exposure to harsh chemicals and high temperatures is unavoidable.

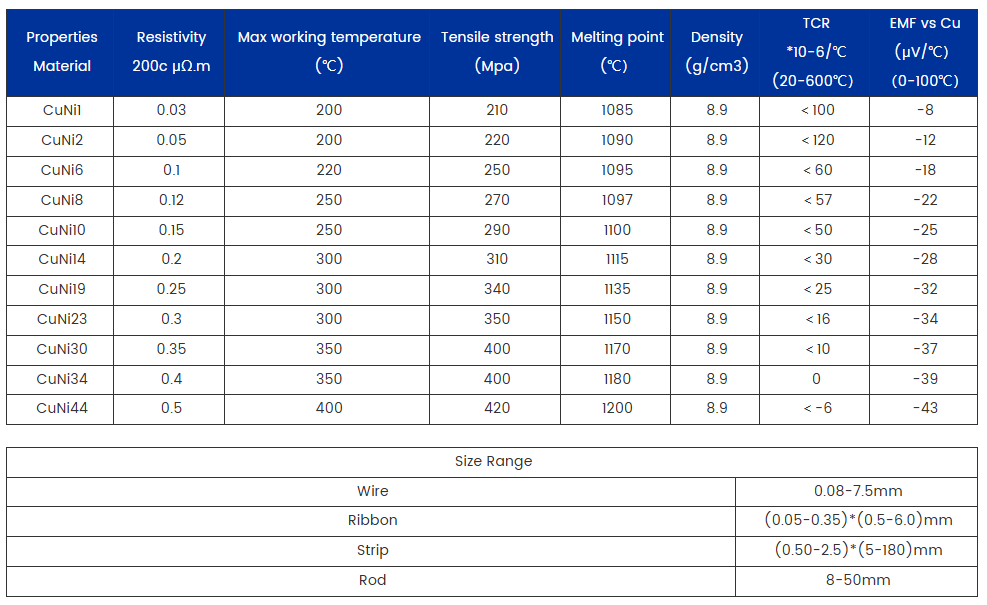

Key Properties of CuNi2 Alloy

Applications of CuNi2 Alloy Bars

User Needs and Demands

The demand for CuNi2 alloy in chemical industries and heat exchangers is driven by several factors, with users focusing on the following key needs:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.