Corrosion-Resistant 4J32 Alloy Wires for Electronics and Semiconductor Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

- Specification

- About Us

- FAQs

- Recommended Products

-

Semiconductor Manufacturing

In semiconductor manufacturing, the thermal stability and corrosion resistance of 4J32 alloy wires are essential for processes such as chip production, wire bonding, and component interconnections. During semiconductor device fabrication, wires are often exposed to elevated temperatures, chemicals, and potential corrosive substances. 4J32 alloy's resilience ensures that semiconductor devices can maintain their functionality and high-performance characteristics even under these challenging conditions.The low thermal expansion of 4J32 also ensures that wires maintain their structural integrity during temperature fluctuations, preventing any distortion that could impact the performance of delicate semiconductor components. This makes 4J32 alloy ideal for bonding wires and connection leads used in microelectronics, integrated circuits, and LED devices.

-

Electronics and Electrical Wiring

Electronics and electrical components require materials that can withstand high temperatures and corrosive environments while maintaining excellent conductivity. 4J32 alloy wires are particularly suitable for high-performance wiring systems used in sensors, power supplies, and circuitry. The corrosion resistance of the alloy is crucial in protecting the integrity of electrical connections, especially in applications where wires are exposed to harsh conditions like moisture, high humidity, or chemicals.In addition, the low CTE of 4J32 alloy ensures that it remains stable when exposed to the thermal cycling experienced in electronics. This makes 4J32 alloy wires essential for high-precision electrical systems that demand high reliability and long-lasting performance.

-

Precision Sensing and Measurement Devices

The corrosion-resistant properties of 4J32 alloy wires make them ideal for use in sensing systems that measure physical parameters such as temperature, pressure, or humidity. These sensors are often employed in aerospace, automotive, and industrial applications, where environmental stability and accuracy are paramount. The durability of 4J32 alloy ensures that these sensors remain functional even in corrosive environments, ensuring reliable operation and accurate readings over time. -

Connector Pins and Leads in Electronics

The use of connector pins and leads in electronics requires materials that can handle continuous operation without failure. 4J32 alloy wire’s resistance to oxidation and corrosion makes it a perfect candidate for connector pins and leads in various electronics and semiconductor devices. Whether used in connectors for computer hardware, mobile devices, or automotive circuits, the strength and durability of 4J32 ensure that electrical connections remain secure and reliable for the lifetime of the product. -

Aerospace and Military Electronics

Electronics used in aerospace and military applications are subject to extreme conditions, including high temperatures, humidity, and exposure to various chemicals. In these environments, reliable, long-lasting performance is essential. 4J32 alloy wires meet these demands by providing thermal stability and corrosion resistance under such harsh conditions. Its use in high-reliability aerospace electronics, such as navigation systems, communication devices, and power electronics, ensures that components continue to operate without degradation, even in demanding environments. -

Corrosion Resistance

Users in the electronics and semiconductor industries require materials that can withstand exposure to moisture, chemicals, and high-humidity environments without degrading over time. Corrosion resistance is a key requirement for materials used in these fields, and 4J32 alloy meets this need. Its ability to resist oxidation ensures that electronics and semiconductor components continue to perform effectively without the risk of corrosion-related failure, enhancing the reliability and lifetime of devices. -

Dimensional Stability and Low Thermal Expansion

Dimensional stability is a crucial property for electronics and semiconductor applications, where precise measurements and uniform behavior are essential. The low coefficient of thermal expansion (CTE) of 4J32 alloy ensures that it does not expand or contract significantly with changes in temperature, maintaining its form and function even under extreme thermal conditions. This makes it ideal for applications that involve temperature fluctuations, where precise performance is required. -

High-Temperature Performance

Electronics and semiconductor components often operate in environments where they are exposed to high temperatures. Whether in power electronics, LED devices, or circuitry, 4J32 alloy offers excellent high-temperature performance, making it a valuable material in devices that require thermal stability without compromising on electrical conductivity or mechanical strength. -

Reliability and Longevity

In industries like semiconductor manufacturing and aerospace electronics, the long-term reliability of components is essential. Durable, corrosion-resistant materials like 4J32 alloy are crucial for meeting these demands, as they help ensure that electrical connections remain intact over the product’s lifespan. This reduces the need for frequent maintenance and replacement, thus improving the cost-effectiveness and efficiency of systems. -

Electrical Conductivity

For many electronic and semiconductor applications, maintaining high electrical conductivity is a key requirement. 4J32 alloy’s unique composition ensures that it provides optimal electrical conductivity while maintaining resistance to corrosion and thermal expansion. This makes it suitable for wiring systems, sensor leads, and connector pins used in high-performance electronics and semiconductor devices.

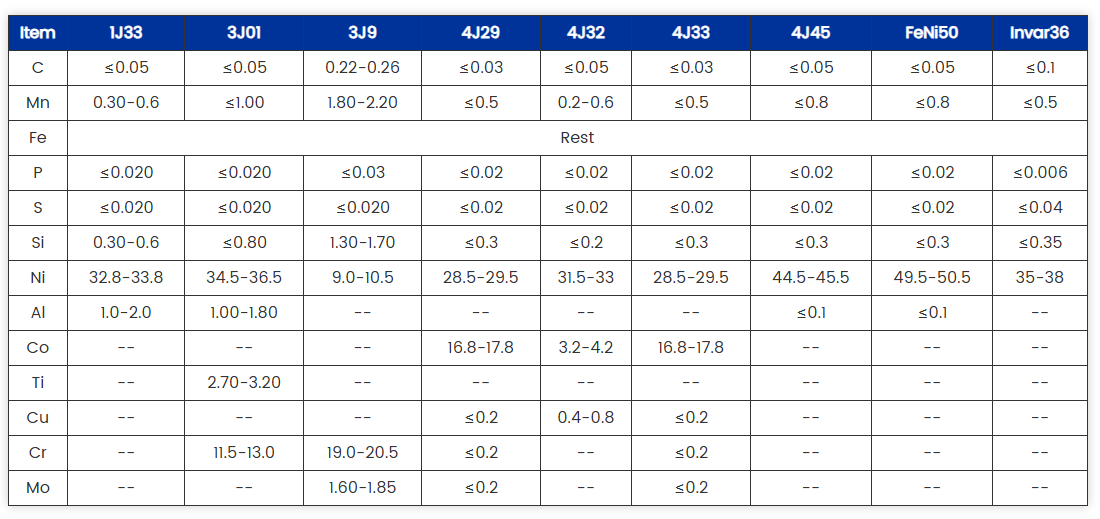

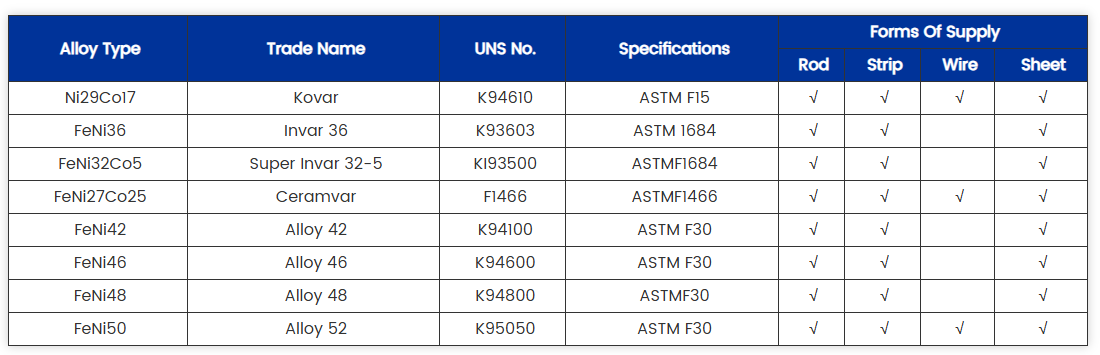

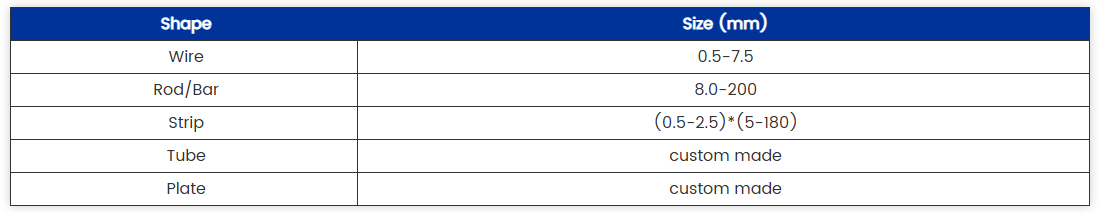

4J32 is a specialized nickel-iron alloy known for its excellent corrosion resistance and thermal stability, making it an ideal choice for electronics and semiconductor applications. This alloy is primarily composed of nickel and iron with a small percentage of other elements, which contribute to its low coefficient of thermal expansion (CTE) and its ability to maintain dimensional accuracy across a wide temperature range. The 4J32 alloy is designed for situations where consistent performance and resistance to corrosion are critical, particularly in environments that involve heat, moisture, or other corrosive elements.

The unique properties of 4J32 alloy wire make it invaluable for electronic components, semiconductor devices, and sensor systems. The durability and reliability of this material ensure that it can withstand harsh environments while maintaining its structural integrity and electrical properties over time.

Applications of 4J32 Alloy Wires

User Demands and Requirements

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

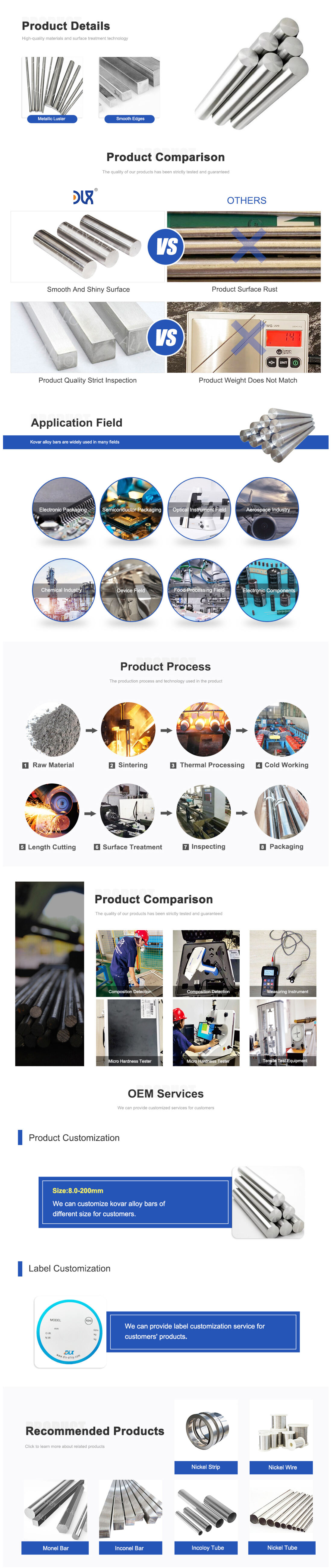

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.