C18150 Chromium Zirconium Copper Plates – High-Strength Alloy for Resistance Welding & Electrical Applications

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

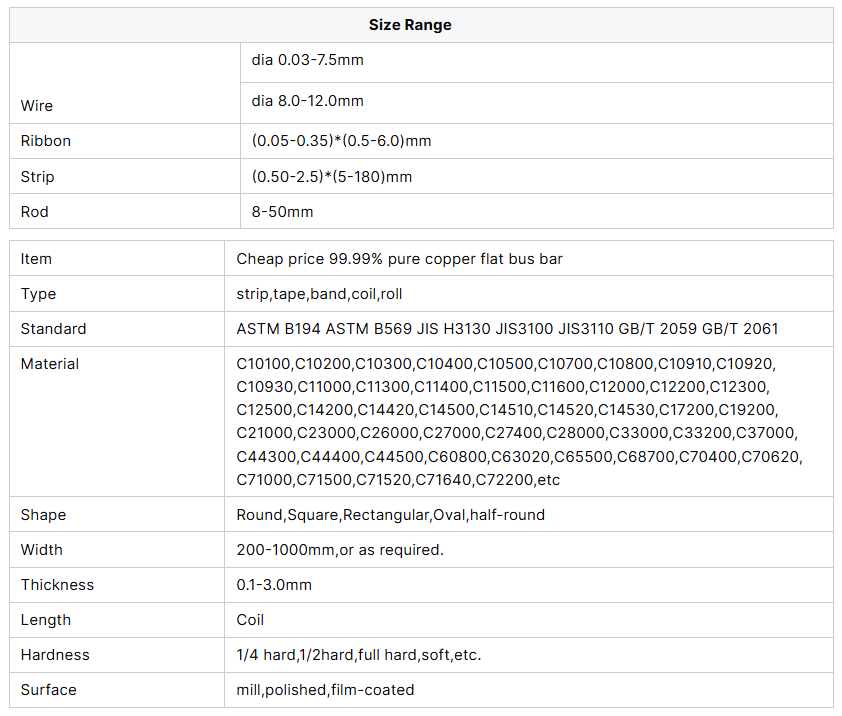

- Specification

- About Us

- FAQs

- Recommended Products

- High electrical and thermal conductivity – Ensures efficient power transmission and heat dissipation.

- Superior strength and hardness – Withstands mechanical stress in high-pressure applications.

- Excellent resistance to softening at elevated temperatures – Retains mechanical properties even under extreme heat.

- Outstanding wear and fatigue resistance – Ideal for applications with repeated thermal and mechanical cycling.

- Corrosion and oxidation resistance – Performs well in industrial and harsh environments.

- Welding electrodes and tips – Ensuring long service life and stable welding performance.

- Seam welding wheels – Providing excellent thermal conductivity for precise and efficient welding.

- Electrode holders and shanks – Withstanding high mechanical and thermal stress in industrial welding processes.

- High-current electrical contacts – Offering minimal resistance and high durability in power transmission.

- Busbars and circuit breaker components – Ensuring stable and efficient electrical performance.

- Transformer and switchgear components – Providing enhanced reliability in high-power applications.

- Industrial furnace components – Retaining strength and conductivity under extreme temperatures.

- Aerospace and automotive heat sinks – Ensuring efficient thermal management.

- Mold and die components – Reducing wear and improving productivity in metal forming applications.

- Extended service life in resistance welding applications – Reducing maintenance and replacement costs.

- Superior electrical performance – Enhancing efficiency in power transmission and electrical systems.

- Precision machining capabilities – Suitable for custom-designed components.

- Reliable performance in extreme conditions – Ensuring durability under heat and mechanical stress.

C18150 chromium zirconium copper is a high-performance copper alloy that combines excellent electrical conductivity with outstanding strength and wear resistance. Designed to withstand extreme heat and mechanical stress, C18150 plates are widely used in resistance welding, electrical contacts, and high-temperature industrial applications. This alloy provides an optimal balance of thermal stability, corrosion resistance, and durability, making it a preferred choice for industries requiring precision and reliability.

Key Properties of C18150 Chromium Zirconium Copper Plates

Applications of C18150 Chromium Zirconium Copper Plates

Resistance Welding Components

C18150 plates are widely used in resistance welding due to their high conductivity and heat resistance. Common applications include:

Electrical and Power Distribution Systems

With its excellent conductivity and durability, C18150 is ideal for electrical applications such as:

High-Temperature Industrial Applications

C18150 plates are used in environments requiring resistance to heat and mechanical stress, including:

Meeting User Needs: Why Choose C18150 Chromium Zirconium Copper Plates

Manufacturers and engineers choose C18150 plates for their unique combination of strength, conductivity, and thermal stability. Key benefits include:

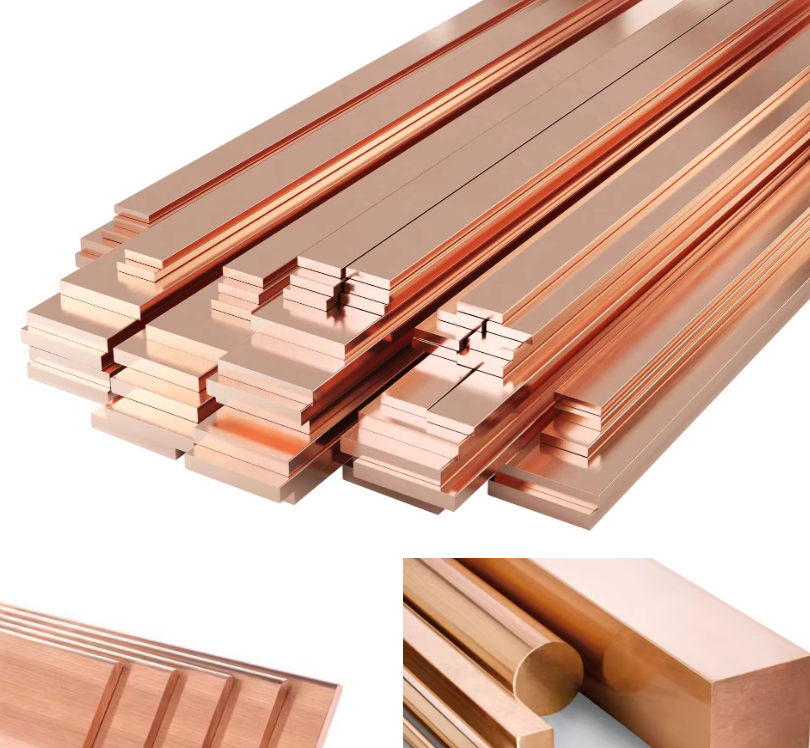

Our products:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.