Nickel Alloy Hastelloy B-2 রাউন্ড বার – উচ্চ শক্তি এবং দurableতা

আমরা ব্যাটচি অর্ডারের জন্য কারখানা সরাসরি মূল্য এবং বিশেষ ছাড় প্রদান করি। আপনি ছোট বা বড় পরিমাণ প্রয়োজন করুন না কেন, আমাদের উত্পাদনসমূহ দ্রুত পাঠানো হয় যেন বিশ্বব্যাপী শিল্পীয় প্রকল্পগুলোর জন্য নির্ভরযোগ্য সরবরাহ থাকে।

- বিবরণ

- স্পেসিফিকেশন

- অ্যাপ্লিকেশন

- সাধারণ জিজ্ঞাসা

- প্রস্তাবিত পণ্য

-

অত্যাধুনিক গর্তকারী প্রতিরোধ: হাইড্রোক্লোরিক এসিড এবং অন্যান্য বেশি প্রতিরোধী পরিবেশে অসাধারণ পারফরম্যান্স।

-

উচ্চ শক্তি এবং দৃঢ়তা: উচ্চ চাপ এবং চরম পরিস্থিতিতেও মেকানিক্যাল সম্পূর্ণতা বজায় রাখে।

-

বিশাল তৈলন ক্ষমতা: সহজে মেশিনিং, ওয়েল্ডিং এবং ফর্মিং করা যায় কার্বাইড জমা হওয়ার সাথে সামান্য পরিবর্তন ছাড়া।

-

অগ্নির উপর উত্তম স্থিতিশীলতা: উচ্চ তাপমাত্রায় ভালভাবে কাজ করে, গর্তকারী প্রতিরোধ এবং বিঘ্ন থেকে বাঁচায়।

-

রসায়ন প্রক্রিয়া শিল্প: রিএক্টর, হিট এক্সচেঞ্জার এবং চাপ বেসেল যেমন করোসিভ রাসায়নিকের সাথে ব্যবহৃত উৎপাদন সরঞ্জামের জন্য আবশ্যক।

-

ঔষধ এবং জৈবপ্রযুক্তি শিল্প: উচ্চ গর্তকারী প্রতিরোধের প্রয়োজনীয়তা থাকা স্টারিল পরিবেশের জন্য আদর্শ।

-

বিদ্যুৎ উৎপাদন এবং শক্তি খন্ড: জিওথার্মাল, নিউক্লিয়ার এবং পেট্রোকেমিক্যাল শিল্পে উচ্চ দৃঢ়তা প্রয়োজনীয় উপাদানের জন্য ব্যবহৃত।

-

আকাশযান এবং মarine প্রকৌশল: আগ্রাসী marine এবং আকাশযান পরিস্থিতিতে ব্যবহৃত কৃত্রিম গঠনের জন্য উপযুক্ত।

-

পেপার ও পাল্প শিল্প: এসিডী এবং কাউস্টিক প্রক্রিয়াজাত রাসায়নিকের সাথে যুক্ত হওয়া যন্ত্রপাতিতে ব্যবহৃত।

-

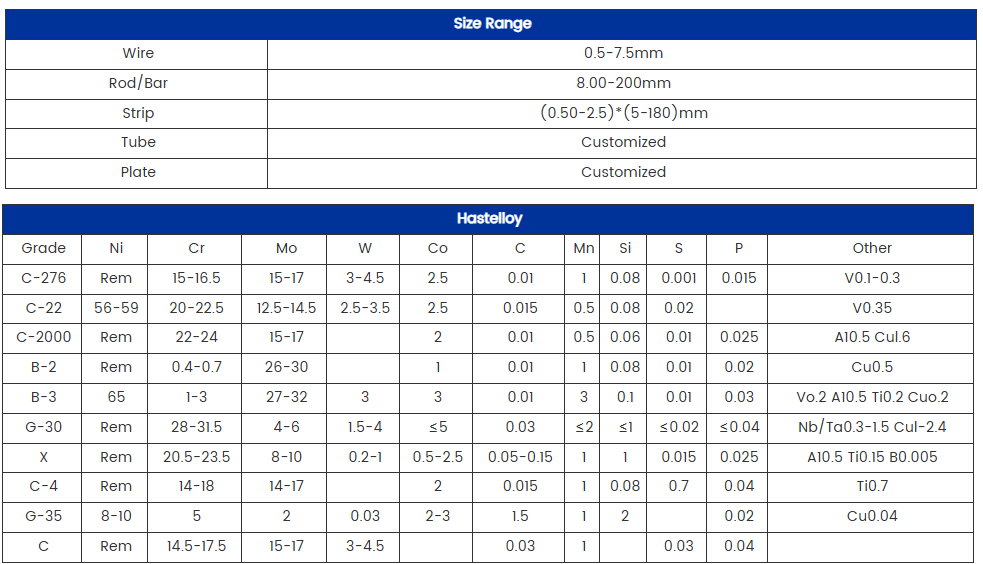

UNS Number: N10665

-

ASTM মান: ASTM B335 (রাউন্ড বার্স এবং রডস)

-

ইন/ডিন সমতুল্য: 2.4617

-

গলন এবং মিশ্রণ: এই মিশ্র ধাতুটি নির্মাণ করা হয় ভ্যাকুম ইনডাকশন গলন (VIM) বা ইলেকট্রিক আর্ক ফার্নেস (EAF) প্রক্রিয়ার মাধ্যমে।

-

হট এবং কোল্ড রোলিং: মেকানিক্যাল বৈশিষ্ট্য বাড়ায় এবং মাত্রাগত সঠিকতা নিশ্চিত করে।

-

হিট ট্রিটমেন্ট (অ্যানিলিং): করোশন রিজিস্টেন্স এবং সাধারণ স্থিতিশীলতা বাড়ায়।

-

সারফেস ফিনিশিং: অপটিমাইজড পারফরম্যান্সের জন্য পিকলিং, প্যাসিভেশন এবং পোলিশিং অন্তর্ভুক্ত।

-

গুণবত্তা পরীক্ষা: মেকানিক্যাল পরীক্ষা, রাসায়নিক বিশ্লেষণ এবং মাত্রাগত পরীক্ষা শিল্প মানের সাথে সামঞ্জস্য নিশ্চিত করে।

হ্যাস্টেলয় বি-2 হল একটি নিকেল-মোলিব্ডেন অ্যালোই যা হাইড্রোক্লোরিক এসিড এর মতো রিডিউসিং পরিবেশে অসাধারণ প্রতিরোধের জন্য পরিচিত। এই উপাদানকে রাউন্ড বার আকারে তৈরি করা হলে এটি অত্যাধুনিক যান্ত্রিক শক্তি, উত্তম করোশন প্রতিরোধ এবং উচ্চ দৈর্ঘ্য প্রদান করে, যা এটিকে চাপিং শিল্প প্রয়োগের জন্য আদর্শ করে তোলে।

উপাদানের রচনা এবং বৈশিষ্ট্য

হ্যাস্টেলয় বি-2 রাউন্ড বারস মূলত নিকেল এবং মোলিব্ডেন দিয়ে গঠিত, যা নিম্নলিখিত সুবিধা প্রদান করে:

হ্যাস্টেলয় B-2 রাউন্ড বারের অ্যাপ্লিকেশন

ঔৎকর্ষপূর্ণ শক্তি এবং গ্রসা প্রতিরোধের কারণে, হ্যাস্টেলয় B-2 রাউন্ড বার ব্যাপকভাবে ব্যবহৃত হয় এমন শিল্পের মধ্যে রয়েছে:

গ্রেড এবং মানদণ্ড

ইন্টারন্যাশনাল মানদণ্ডের সাথে হ্যাস্টেলয় B-2 রাউন্ড বার মেলে যা উচ্চ গুণবত্তা এবং পারফরম্যান্স নিশ্চিত করে:

উৎপাদন প্রক্রিয়া

হাস্টেলয় বি-২ রাউন্ড বার এর উৎপাদন প্রক্রিয়াটি জটিল গুণবত্তা নিয়ন্ত্রণ পদ্ধতি অনুসরণ করে যা শুদ্ধতা এবং দীর্ঘস্থায়ীত্ব নিশ্চিত করে:

FAQs:

ডেলিভারি সময় কত?

এটি অর্ডারের পরিমাণের উপর নির্ভর করে, ছোট অর্ডারের জন্য 10-30 দিন। বড় অর্ডারের জন্য এটি 60 দিন সময় নেয়।

আপনারা OEM/ODM উৎপাদন গ্রহণ করেন কি?

হ্যাঁ! আমরা OEM/ODM উৎপাদন গ্রহণ করি। আপনি আমাদের আপনার নমুনা বা ড্রাইং পাঠাতে পারেন।

আপনারা আপনাদের পণ্যের গুণবত্তা কিভাবে নিয়ন্ত্রণ করেন? পণ্যের রসায়নিক বৈশিষ্ট্য গুণবত্তা মানদণ্ড পূরণ করে কি?

পেশাদার গুণবত্তা দলের সাথে, উন্নত পণ্য গুণবত্তা পরিকল্পনা, কঠোর বাস্তবায়ন এবং অবিচ্ছিন্ন উন্নতির মাধ্যমে, আমরা পণ্য গুণবত্তা পরীক্ষা সার্টিফিকেট প্রদান করব, যাতে রসায়নিক বিশ্লেষণের রিপোর্ট অন্তর্ভুক্ত থাকবে।

আপনার কোম্পানি বিস্তারিত তথ্য ও ড্রাইং প্রদান করতে পারে কি?

হ্যাঁ, আপনি পারেন। দয়া করে আমাদের জানান যে আপনি কোন পণ্য এবং অ্যাপ্লিকেশন প্রয়োজন, এবং আমরা আপনাকে বিস্তারিত তথ্য এবং ড্রাইং পাঠাব যাতে আপনি এটি মূল্যায়ন এবং নিশ্চিত করতে পারেন।

আপনারা পূর্ব-বিক্রয় এবং পরবর্তী-বিক্রয় সেবা কিভাবে পরিচালনা করেন?

আমাদের একটি পেশাদার ব্যবসা দল রয়েছে যারা এক-এক করে আপনার পণ্যের প্রয়োজন সুরক্ষিত রাখবে, এবং যদি আপনার কোন প্রশ্ন থাকে, সে আপনাকে উত্তর দিতে পারবে!

আমি অর্ডার দেওয়ার আগে তোমাদের কারখানা দেখতে যেতে পারি?

হ্যাঁ, আপনি আমাদের কারখানা দেখতে স্বাগত। আমরা পরস্পরকে জানার এই সুযোগে খুশি হচ্ছি।

আপনাদের উৎপাদন ভিত্তি কোথায়?

আমরা চীনের জিয়াংসুতে আমাদের পণ্য উৎপাদন করি এবং চীন থেকে আপনাদের দেশে সম্ভবত সবচেয়ে শীঘ্র পাঠাই, যা সাধারণত আপনার পণ্য প্রয়োজন এবং পরিমাণের উপর নির্ভর করে।

আপনি নমুনা পাঠাতে পারেন?

হ্যাঁ, আমরা পাঠাতে পারি।