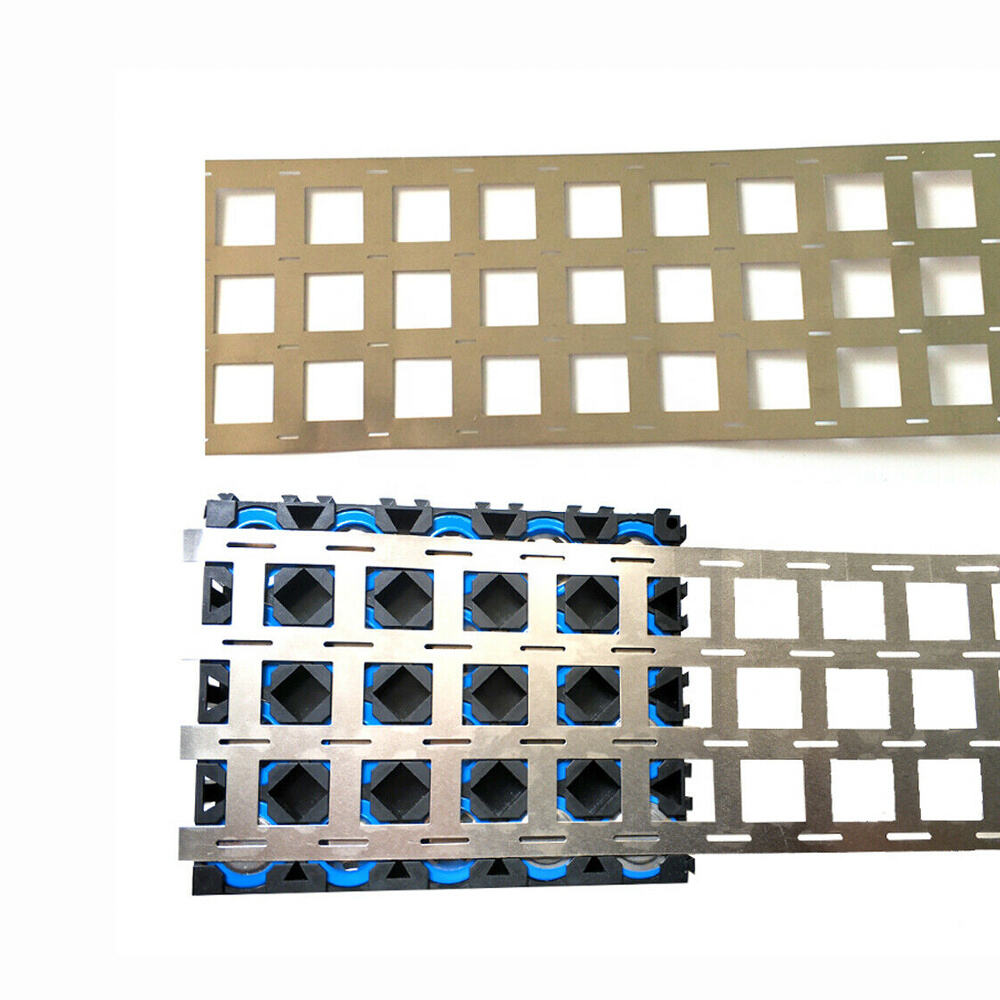

ব্যাটারি ওয়েল্ডিং এবং বিদ্যুৎ পরিবহনের জন্য N6 নিকেল স্ট্রিপ 0.1mm-0.3mm

আমরা ব্যাটচি অর্ডারের জন্য কারখানা সরাসরি মূল্য এবং বিশেষ ছাড় প্রদান করি। আপনি ছোট বা বড় পরিমাণ প্রয়োজন করুন না কেন, আমাদের উত্পাদনসমূহ দ্রুত পাঠানো হয় যেন বিশ্বব্যাপী শিল্পীয় প্রকল্পগুলোর জন্য নির্ভরযোগ্য সরবরাহ থাকে।

- সারাংশ

- স্পেসিফিকেশন

- অ্যাপ্লিকেশন

- সাধারণ জিজ্ঞাসা

- প্রস্তাবিত পণ্য

N6 নিকেল স্ট্রিপ-এর পরিচিতি

N6 নিকেল স্ট্রিপ একটি উচ্চতম শোধিত (≥99.6% Ni) নিকেল পদার্থ, যা অত্যাধুনিক গ্রেডের করোশন বিরোধিতা, উত্তম বিদ্যুৎ পরিবহন এবং উচ্চ যান্ত্রিক শক্তি প্রদান করে। এটি ব্যাটারি তৈরি, ইলেকট্রনিক্স উপাদান এবং বিদ্যুৎ পরিবহনের অ্যাপ্লিকেশনে ব্যাপকভাবে ব্যবহৃত হয়, যা নির্দিষ্ট শিল্পে ভরসার ও উচ্চ-পারফরম্যান্সের নিকেল স্ট্রিপের জন্য প্রধান উপকরণ হিসেবে বিবেচিত।

আমাদের ফ্যাক্টরি ব্যবহারকারীর জন্য ব্যবহার ভিত্তিক মোটা হাইট (0.1mm-0.3mm) এবং ব্যাচ আকারে পণ্যের সরবরাহ করে, যা শিল্প অ্যাপ্লিকেশনের জন্য উচ্চ গুণবত্তা নিশ্চিত করে।

N6 নিকেল স্ট্রিপের প্রধান বৈশিষ্ট্য

উচ্চ শোধিত নিকেল (≥99.6%) – উত্তম পরিবহন এবং দীর্ঘ জীবন নিশ্চিত করে।

অত্যাধুনিক করোশন বিরোধিতা – এটি এসিডিক, ক্ষারীয় এবং উচ্চ আর্দ্রতা পরিবেশেও ভালভাবে কাজ করে।

উত্তম বিদ্যুৎ ও তাপ পরিবহন – ব্যাটারি কানেক্টর, বিদ্যুৎ প্রেরণ এবং ইলেকট্রিক্যাল অ্যাপ্লিকেশনের জন্য উপযুক্ত।

উচ্চ ডাকটিলিটি এবং ভালো ওয়েল্ডাবিলিটি - ব্যাটারি ট্যাব, কনেক্টর এবং নির্দিষ্ট অংশগুলি আকৃতি দেওয়া এবং ওয়েল্ড করা সহজ।

ফ্যাক্টরি সরাসরি মূল্য - স্বayed সাইজ এবং OEM সমর্থন উপলব্ধ।

N6 নিকেল স্ট্রিপের অ্যাপ্লিকেশন

1. ব্যাটারি তৈরি এবং ওয়েল্ডিং অ্যাপ্লিকেশন

লিথিয়াম-আয়ন, নিকেল-মেটাল হাইড্রাইড (NiMH) এবং অ্যালকেলাইন ব্যাটারি প্যাক জমা দেওয়াতে ব্যবহৃত।

ব্যাটারি ট্যাব কনেক্টর, ইলেক্ট্রোড ওয়েল্ডিং এবং সেল ইন্টারকনেকশনের জন্য প্রয়োজনীয়।

নিম্ন রেজিস্টান্স এবং উচ্চ চালকত্ব প্রদান করে, কার্যকর শক্তি প্রবাহ এবং ব্যাটারির জীবন বৃদ্ধির জন্য নিশ্চিত করে।

2. বিদ্যুৎ এবং ইলেকট্রনিক্স উপাদান

সার্কিট বোর্ড, ইলেকট্রিকাল বাস বার এবং শক্তি প্রেরণ ব্যবস্থায় ব্যবহৃত।

শক্তি সঞ্চয় ডিভাইস এবং ফুয়েল সেলে বর্তনী সংগ্রহকারী হিসাবে কাজ করে।

ইলেকট্রোম্যাগনেটিক ইন্টারফেরেন্স (EMI) কমানোর জন্য শিল্ডিং অ্যাপ্লিকেশনে ব্যবহৃত।

৩. শিল্প এবং রসায়ন প্রক্রিয়া সজ্জা

অম্লজাত এবং ক্ষারজাত পরিবেশের বিরুদ্ধে প্রতিরোধী, এটি রসায়ন প্রক্রিয়া গাদির জন্য আদর্শ।

করোশন-প্রতিরোধী ইলেকট্রিকাল যোগাযোগ এবং শিল্প হিটিং উপাদানে ব্যবহৃত।

৪. এয়ারোস্পেস এবং মেরিন অ্যাপ্লিকেশন

উচ্চ তাপমাত্রা এবং করোশন-প্রতিরোধী পরিবেশের জন্য উপযুক্ত।

মেরিন এবং এয়ারোস্পেস শিল্পের উচ্চ-পারফরম্যান্স ওয়েল্ডিং এবং গঠনমূলক উপাদানে ব্যবহৃত।

| স্পেসিফিকেশন | বিস্তারিত |

|---|---|

| উপাদান | N6 শুদ্ধ নিকেল (≥99.6%) |

| মোটা | 0.1mm – 0.3mm (맞춤형) |

| প্রস্থ | ৩০০mm পর্যন্ত (맞춤형) |

| মান মেনকম | এএসটিএম বি১৬২, জিবি/টি ২০৫৪-২০০৫ |

| গলন পয়েন্ট | ১৪৫৩°সি (২৬৪৭°ফ) |

| টেনসাইল শক্তি | ≥৩৮০ এমপিা |

| বৈদ্যুতিক প্রতিরোধ | ≤০.০৯৯ Ω·mm²/m |

আমাদের N6 নিকেল স্ট্রিপ কেন বাছাই করবেন?

বৈদ্যুতিক অ্যাপ্লিকেশনের জন্য উচ্চ শোধকতা এবং স্থিতিশীল পারফরম্যান্স

ব্যাটচ অর্ডারের জন্য ব্যাবহার জনিত মোটা-চওড়া বিকল্প পাওয়া যায়

ফ্যাক্টরি ডায়েক্ট সাপ্লাই – প্রতিদ্বন্দ্বিতামূলক মূল্য এবং নির্ভরযোগ্য গুণবত্তা

গুরুতর বিশ্বব্যাপী পাঠানো এবং OEM প্রসেসিং সাপোর্ট

FAQs:

ডেলিভারি সময় কত?

এটি অর্ডারের পরিমাণের উপর নির্ভর করে, ছোট অর্ডারের জন্য 10-30 দিন। বড় অর্ডারের জন্য এটি 60 দিন সময় নেয়।

আপনারা OEM/ODM উৎপাদন গ্রহণ করেন কি?

হ্যাঁ! আমরা OEM/ODM উৎপাদন গ্রহণ করি। আপনি আমাদের আপনার নমুনা বা ড্রাইং পাঠাতে পারেন।

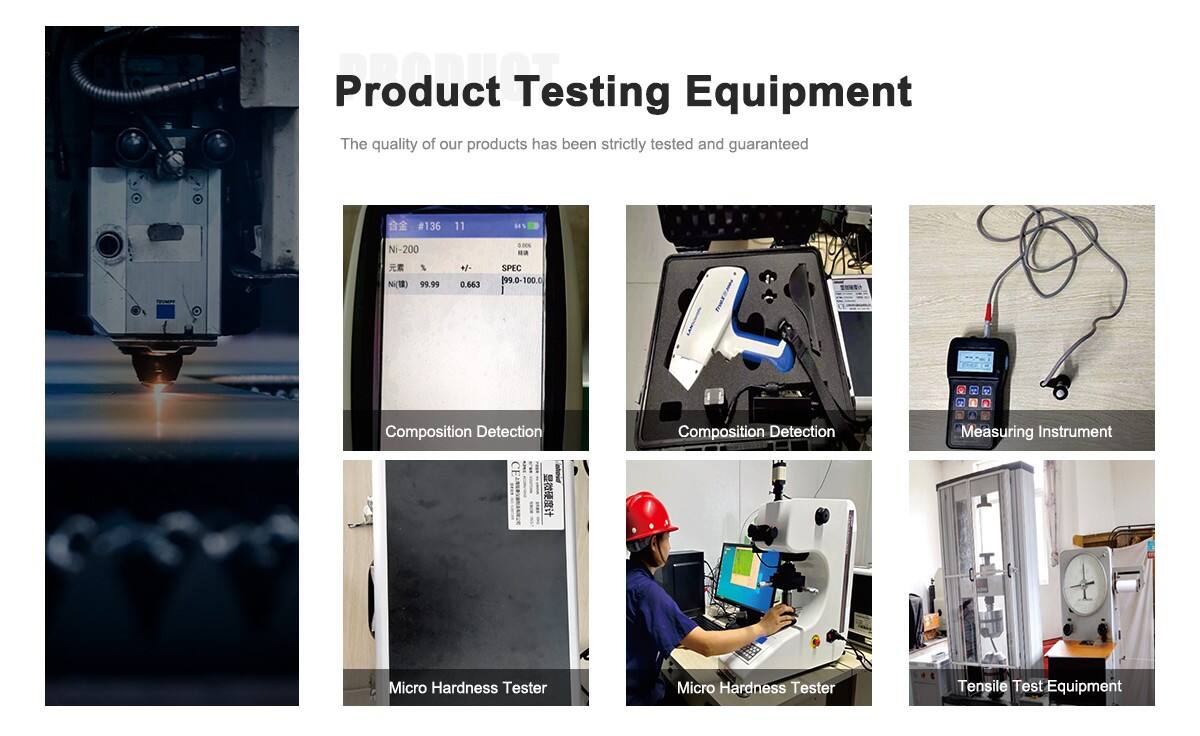

আপনারা আপনাদের পণ্যের গুণবত্তা কিভাবে নিয়ন্ত্রণ করেন? পণ্যের রসায়নিক বৈশিষ্ট্য গুণবত্তা মানদণ্ড পূরণ করে কি?

পেশাদার গুণবত্তা দলের সাথে, উন্নত পণ্য গুণবত্তা পরিকল্পনা, কঠোর বাস্তবায়ন এবং অবিচ্ছিন্ন উন্নতির মাধ্যমে, আমরা পণ্য গুণবত্তা পরীক্ষা সার্টিফিকেট প্রদান করব, যাতে রসায়নিক বিশ্লেষণের রিপোর্ট অন্তর্ভুক্ত থাকবে।

আপনার কোম্পানি বিস্তারিত তথ্য ও ড্রাইং প্রদান করতে পারে কি?

হ্যাঁ, আপনি পারেন। দয়া করে আমাদের জানান যে আপনি কোন পণ্য এবং অ্যাপ্লিকেশন প্রয়োজন, এবং আমরা আপনাকে বিস্তারিত তথ্য এবং ড্রাইং পাঠাব যাতে আপনি এটি মূল্যায়ন এবং নিশ্চিত করতে পারেন।

আপনারা পূর্ব-বিক্রয় এবং পরবর্তী-বিক্রয় সেবা কিভাবে পরিচালনা করেন?

আমাদের একটি পেশাদার ব্যবসা দল রয়েছে যারা এক-এক করে আপনার পণ্যের প্রয়োজন সুরক্ষিত রাখবে, এবং যদি আপনার কোন প্রশ্ন থাকে, সে আপনাকে উত্তর দিতে পারবে!

আমি অর্ডার দেওয়ার আগে তোমাদের কারখানা দেখতে যেতে পারি?

হ্যাঁ, আপনি আমাদের কারখানা দেখতে স্বাগত। আমরা পরস্পরকে জানার এই সুযোগে খুশি হচ্ছি।

আপনাদের উৎপাদন ভিত্তি কোথায়?

আমরা চীনের জিয়াংসুতে আমাদের পণ্য উৎপাদন করি এবং চীন থেকে আপনাদের দেশে সম্ভবত সবচেয়ে শীঘ্র পাঠাই, যা সাধারণত আপনার পণ্য প্রয়োজন এবং পরিমাণের উপর নির্ভর করে।

আপনি নমুনা পাঠাতে পারেন?

হ্যাঁ, আমরা পাঠাতে পারি।