এনডাস্ট্রিয়াল Hastelloy C-4 শীট – ভরসার্থ সাপ্লাইয়ার এবং সেরা মূল্য

আমরা ব্যাটচি অর্ডারের জন্য কারখানা সরাসরি মূল্য এবং বিশেষ ছাড় প্রদান করি। আপনি ছোট বা বড় পরিমাণ প্রয়োজন করুন না কেন, আমাদের উত্পাদনসমূহ দ্রুত পাঠানো হয় যেন বিশ্বব্যাপী শিল্পীয় প্রকল্পগুলোর জন্য নির্ভরযোগ্য সরবরাহ থাকে।

- সারাংশ

- স্পেসিফিকেশন

- অ্যাপ্লিকেশন

- সাধারণ জিজ্ঞাসা

- প্রস্তাবিত পণ্য

-

অসাধারণ করোজন প্রতিরোধ: পিটিং, ক্রেভ করোজন এবং স্ট্রেস করোজন ফ্র্যাকচারিং-এর বিরুদ্ধে অত্যন্ত প্রতিরোধশীল।

-

উচ্চ তাপমাত্রা স্থিতিশীলতা: চরম তাপমাত্রার শর্তগুলোতে যান্ত্রিক সম্পূর্ণতা বজায় রাখে।

-

ঔৎকৃষ্ট নির্মাণযোগ্যতা: জটিল আকৃতিতে সহজে হাঁটু দেওয়া, যন্ত্রণা এবং আকৃতি দেওয়া যায়।

-

শক্তিশালী রাসায়নিক প্রতিরোধ: অম্লজাত এবং অক্সিডেশন প্রবণ পরিবেশে ভালোভাবে কাজ করে।

-

রাসায়নিক প্রক্রিয়া শিল্প: কঠিন রাসায়নিকের বিরুদ্ধে প্রতিরোধশীল রিএক্টর, হিট এক্সচেঞ্জার এবং পাইপিং সিস্টেমে ব্যবহৃত।

-

বিমান ও মারিন প্রকৌশল: চরম তাপমাত্রা এবং করোজন প্রবণ পরিবেশে ব্যবহারের জন্য আদর্শ।

-

ঔষধ এবং খাদ্য শিল্প: যেখানে স্বাস্থ্য এবং দৃঢ়তা গুরুত্বপূর্ণ, সেখানে প্রক্রিয়া ট্যাঙ্ক এবং স্টারিলাইজেশন উপকরণে প্রযোজ্য।

-

বিদ্যুৎ উৎপাদন: উচ্চ-পারফরম্যান্স উপাদান প্রয়োজনীয় হাড়োয়ার এবং জিওথার্মাল প্ল্যান্টে ব্যবহৃত।

-

ফ্লু গ্যাস স্ক্রাবিং সিস্টেম: আগ্রাসী গ্যাসের বিরুদ্ধে প্রতিরোধশীলতা প্রয়োজনীয় দূষণ নিয়ন্ত্রণ অ্যাপ্লিকেশনের জন্য উপযুক্ত।

-

UNS Number: N06455

-

এসটিএম মানদণ্ড: ASTM B575 (শীট এবং স্ট্রিপস), ASTM B619/B622 (পাইপ ও টিউব)

-

ইনি/ডিনি সমতুল্য: 2.4610

-

গলন এবং মিশ্রণ: এলয়েট তৈরি করা হয় ভ্যাকুয়াম ইনডাকশন মেল্টিং (ভিআইএম) বা ইলেকট্রিক আর্ক ফার্নেস (ইএএফ) পদ্ধতি ব্যবহার করে।

-

রোলিং এবং ফর্মিং: পদার্থটি গরম এবং ঠাণ্ডা রোলিংয়ের মাধ্যমে সঠিক মোটা এবং যান্ত্রিক বৈশিষ্ট্য অর্জন করে।

-

অ্যানিলিং: তাপ চিকিৎসা দ্বারা করোশন রেজিস্টেন্স এবং দুর্বলতা বাড়ানো হয়।

-

সারফেস ফিনিশিং: পিকলিং এবং পাসিভেশন পরিচালিত হয় একটি পরিষ্কার, করোশন-রেজিস্টেন্ট সারফেস পেতে।

-

গুণবত্তা নিয়ন্ত্রণ: শক্ত পরীক্ষা, যার মধ্যে টেনশন শক্তি, কঠিনতা এবং রাসায়নিক গঠন বিশ্লেষণ রয়েছে, শিল্প মানদণ্ডের সাথে মেলানোর জন্য।

-

মোটা এবং মাত্রা ব্যবস্থাপনা: শীটগুলি সঠিক বিন্যাসে কাটা হয়।

-

সারফেস ফিনিশ বিকল্প: পোলিশড, ব্রাশড বা মিল ফিনিশ দিয়ে পাওয়া যায়।

-

আকৃতি দেওয়া এবং জোড়া: বিভিন্ন নির্মাণ পদ্ধতির সঙ্গে সুবিধাজনক করে নিশ্চিত করা।

-

নিয়মাবলী মেনে চলা: পদার্থগুলি ASTM, ASME এবং অন্যান্য আন্তর্জাতিক মানদণ্ড মেনে চলতে হবে।

-

িল খ্যাতি: উচ্চ-গুণবত্তার Hastelloy C-4 শীট সরবরাহ করার ইতিহাস রয়েছে এমন সরবরাহকারীদের খুঁজুন।

-

সনদপত্র এবং মানদণ্ড: আন্তর্জাতিক উৎপাদন এবং নিরাপত্তা মানদণ্ডের সাথে মেনে চলা নিশ্চিত করুন।

-

প্রতিযোগিতামূলক মূল্য: বাজারের হার তুলনা করুন যেন লাগত এবং গুণবত্তা উভয়ই সেরা পান।

-

শৈশব ক্ষমতা: বিশেষ শিল্প প্রয়োজনের সাথে মেলে যাওয়া এমন সমাধান প্রদান করে এমন সরবরাহকারীদের নির্বাচন করুন।

পরিচিতি

হ্যাস্টেলয় সি-4 একটি নিকেল-ভিত্তিক উপাদান যা তার অসাধারণ করোশন প্রতিরোধ এবং উচ্চ তাপমাত্রায় স্থিতিশীলতার জন্য পরিচিত। শীটের আকারে তৈরি করা হয়েছে, এই উপাদানটি গুরুত্বপূর্ণ পারফরম্যান্স প্রয়োজনের জন্য ব্যাপকভাবে ব্যবহৃত হয় এক্সট্রিম রাসায়নিক পরিবেশে। একজন নির্ভরযোগ্য সাপ্লাইয়ার নির্বাচন করা উচ্চ গুণবত্তার উপাদান এবং সেরা মূল্য নিশ্চিত করে, যা শিল্পী খরিদকারীদের জন্য অত্যন্ত গুরুত্বপূর্ণ।

উপাদানের রচনা এবং বৈশিষ্ট্য

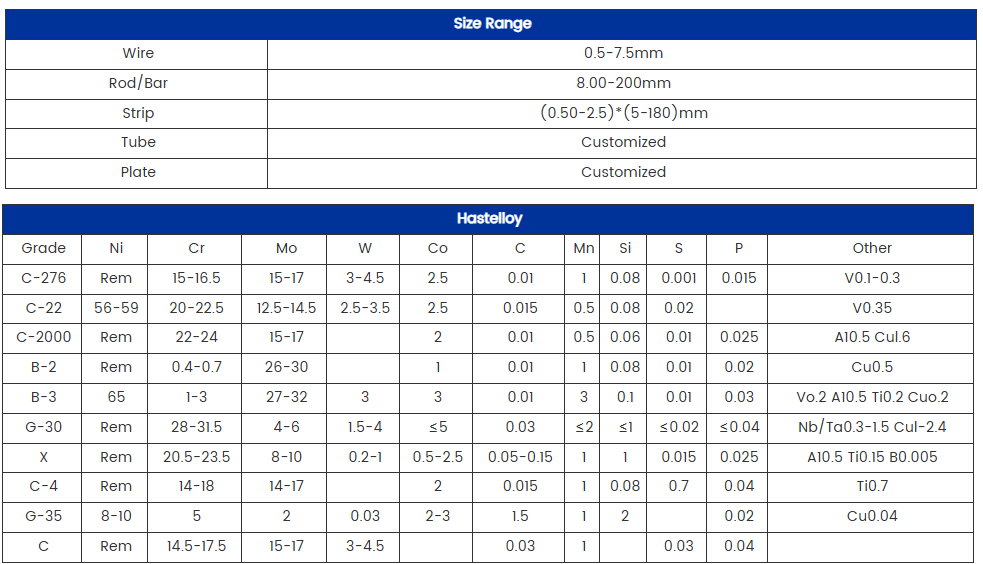

হ্যাস্টেলয় সি-4 মূলত নিকেল দ্বারা গঠিত, মোলিব্ডেন এবং ক্রোমিয়ামের উল্লেখযোগ্য পরিমাণও রয়েছে। এই বিশেষ গঠন নিম্নলিখিত সুবিধা প্রদান করে:

হ্যাস্টেলয় সি-৪ শীটের ব্যবহার

হ্যাস্টেলয় সি-৪ শীটগুলি বিভিন্ন শিল্প খন্ডে ব্যবহৃত হয়, যার মধ্যে রয়েছে:

গ্রেড এবং মানদণ্ড

হ্যাস্টেলয় C-4 বহুমাত্রিক আন্তর্জাতিক মানদণ্ডে উপলব্ধ যা বিভিন্ন শিল্পীয় প্রয়োজন পূরণ করে:

উৎপাদন প্রক্রিয়া

হ্যাস্টেলয় C-4 শিটস তৈরির জন্য একটি কঠোর প্রক্রিয়া অনুসরণ করা হয় যেন গুণবত্তা এবং পারফরম্যান্স নিশ্চিত থাকে:

ব্যবহারকারীর প্রয়োজন এবং ব্যবস্থানুযায়ী সামগ্রী

হ্যাস্টেলয় C-4 শীটের ক্রেতারা অনেক সময় বিশেষ প্রয়োজনের জন্য ব্যবহার উপযোগী সমাধান প্রয়োজন। সাধারণ প্রয়োজনগুলির মধ্যে রয়েছে:

নির্ভরযোগ্য সরবরাহকারী & সেরা মূল্য

গুণবত্তা ও খরচের কার্যকারিতা নিশ্চিত করতে, একজন বিশ্বস্ত সরবরাহকারী নির্বাচন করা অত্যাবশ্যক। সরবরাহকারী নির্বাচনের মূল উপাদানগুলি হলো:

FAQs:

ডেলিভারি সময় কত?

এটি অর্ডারের পরিমাণের উপর নির্ভর করে, ছোট অর্ডারের জন্য 10-30 দিন। বড় অর্ডারের জন্য এটি 60 দিন সময় নেয়।

আপনারা OEM/ODM উৎপাদন গ্রহণ করেন কি?

হ্যাঁ! আমরা OEM/ODM উৎপাদন গ্রহণ করি। আপনি আমাদের আপনার নমুনা বা ড্রাইং পাঠাতে পারেন।

আপনারা আপনাদের পণ্যের গুণবত্তা কিভাবে নিয়ন্ত্রণ করেন? পণ্যের রসায়নিক বৈশিষ্ট্য গুণবত্তা মানদণ্ড পূরণ করে কি?

পেশাদার গুণবত্তা দলের সাথে, উন্নত পণ্য গুণবত্তা পরিকল্পনা, কঠোর বাস্তবায়ন এবং অবিচ্ছিন্ন উন্নতির মাধ্যমে, আমরা পণ্য গুণবত্তা পরীক্ষা সার্টিফিকেট প্রদান করব, যাতে রসায়নিক বিশ্লেষণের রিপোর্ট অন্তর্ভুক্ত থাকবে।

আপনার কোম্পানি বিস্তারিত তথ্য ও ড্রাইং প্রদান করতে পারে কি?

হ্যাঁ, আপনি পারেন। দয়া করে আমাদের জানান যে আপনি কোন পণ্য এবং অ্যাপ্লিকেশন প্রয়োজন, এবং আমরা আপনাকে বিস্তারিত তথ্য এবং ড্রাইং পাঠাব যাতে আপনি এটি মূল্যায়ন এবং নিশ্চিত করতে পারেন।

আপনারা পূর্ব-বিক্রয় এবং পরবর্তী-বিক্রয় সেবা কিভাবে পরিচালনা করেন?

আমাদের একটি পেশাদার ব্যবসা দল রয়েছে যারা এক-এক করে আপনার পণ্যের প্রয়োজন সুরক্ষিত রাখবে, এবং যদি আপনার কোন প্রশ্ন থাকে, সে আপনাকে উত্তর দিতে পারবে!

আমি অর্ডার দেওয়ার আগে তোমাদের কারখানা দেখতে যেতে পারি?

হ্যাঁ, আপনি আমাদের কারখানা দেখতে স্বাগত। আমরা পরস্পরকে জানার এই সুযোগে খুশি হচ্ছি।

আপনাদের উৎপাদন ভিত্তি কোথায়?

আমরা চীনের জিয়াংসুতে আমাদের পণ্য উৎপাদন করি এবং চীন থেকে আপনাদের দেশে সম্ভবত সবচেয়ে শীঘ্র পাঠাই, যা সাধারণত আপনার পণ্য প্রয়োজন এবং পরিমাণের উপর নির্ভর করে।

আপনি নমুনা পাঠাতে পারেন?

হ্যাঁ, আমরা পাঠাতে পারি।