ERNiCrMo-4 (C-276) Welding Wire for Chemical & Power Plants – Special Offers

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6

- Overview

- Recommended Products

Introduction to ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 (C-276) welding wire is a nickel-chromium-molybdenum alloy designed for welding high-performance, corrosion-resistant materials in chemical processing and power generation industries. Recognized for its outstanding resistance to corrosive environments, high temperatures, and extreme pressures, this welding wire is widely used for critical applications in chemical plants, nuclear facilities, and power stations.

We offer special discounts on bulk orders, ensuring that industries requiring high-strength, reliable welding solutions get the best prices. With factory-direct supply, strict quality control, and fast global delivery, our ERNiCrMo-4 (C-276) welding wire is the ideal choice for industrial-grade welding projects.

Material Overview: Properties of ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 (C-276), commonly known as Hastelloy® C-276, provides superior metallurgical properties for welding in harsh industrial environments.

✔ Excellent Corrosion Resistance – Resists oxidation, pitting, crevice corrosion, and stress corrosion cracking in acidic and chloride-rich environments.

✔ High-Temperature Strength – Maintains mechanical integrity in temperatures up to 1093°C (2000°F).

✔ Superior Weldability – Produces strong, defect-free welds with minimal hot cracking.

✔ Resistance to Sulfide & Chloride Stress Cracking – Ensures durability in chemical plants and power plants.

✔ High Mechanical Strength – Withstands high-stress applications in extreme conditions.

These properties make ERNiCrMo-4 welding wire a critical material for industrial applications where safety, durability, and corrosion resistance are top priorities.

| Standard | Specification |

|---|---|

| AWS A5.14 | ERNiCrMo-4 |

| UNS Number | N10276 |

| ASTM Standard | ASTM B574, ASTM B575 |

| ISO Standard | ISO 18274: NiCr15Mo16Fe6W4 |

Applications of ERNiCrMo-4 (C-276) Welding Wire

1. Chemical Processing Industry

Acidic Storage Tanks & Pipelines – Withstands hydrochloric, sulfuric, and nitric acid exposure.

Heat Exchangers & Pressure Vessels – Provides long-term durability in high-pressure conditions.

Chemical Reactor Vessels – Resists corrosive gases and thermal expansion stresses.

2. Power Generation & Nuclear Industry

Nuclear Reactor Components – Ensures radiation and heat resistance for nuclear power plants.

Steam & Gas Turbines – Protects against oxidation and extreme thermal cycling.

Boiler Tubing & Heat Recovery Systems – Prevents corrosion-related failures in power plants.

3. Oil & Gas Refineries

Pipeline & Offshore Equipment – Resistant to hydrogen sulfide (H₂S) and extreme pressure.

Crude Oil Processing Units – Withstands high-temperature sulfuric environments.

4. Aerospace & Marine Engineering

Jet Engine & Exhaust Systems – Ideal for high-temperature, high-pressure applications.

Shipbuilding & Seawater Piping – Ensures corrosion-free performance in saltwater environments.

5. Food & Pharmaceutical Industry

Sanitary Welding for Food-Grade Equipment – Maintains hygienic and contamination-free processing.

Sterilization Equipment & Medical Devices – Ensures biocompatibility and durability.

Why Choose Our ERNiCrMo-4 (C-276) Welding Wire?

Special Bulk Order Discounts – Limited-time offers for chemical and power plant industries.

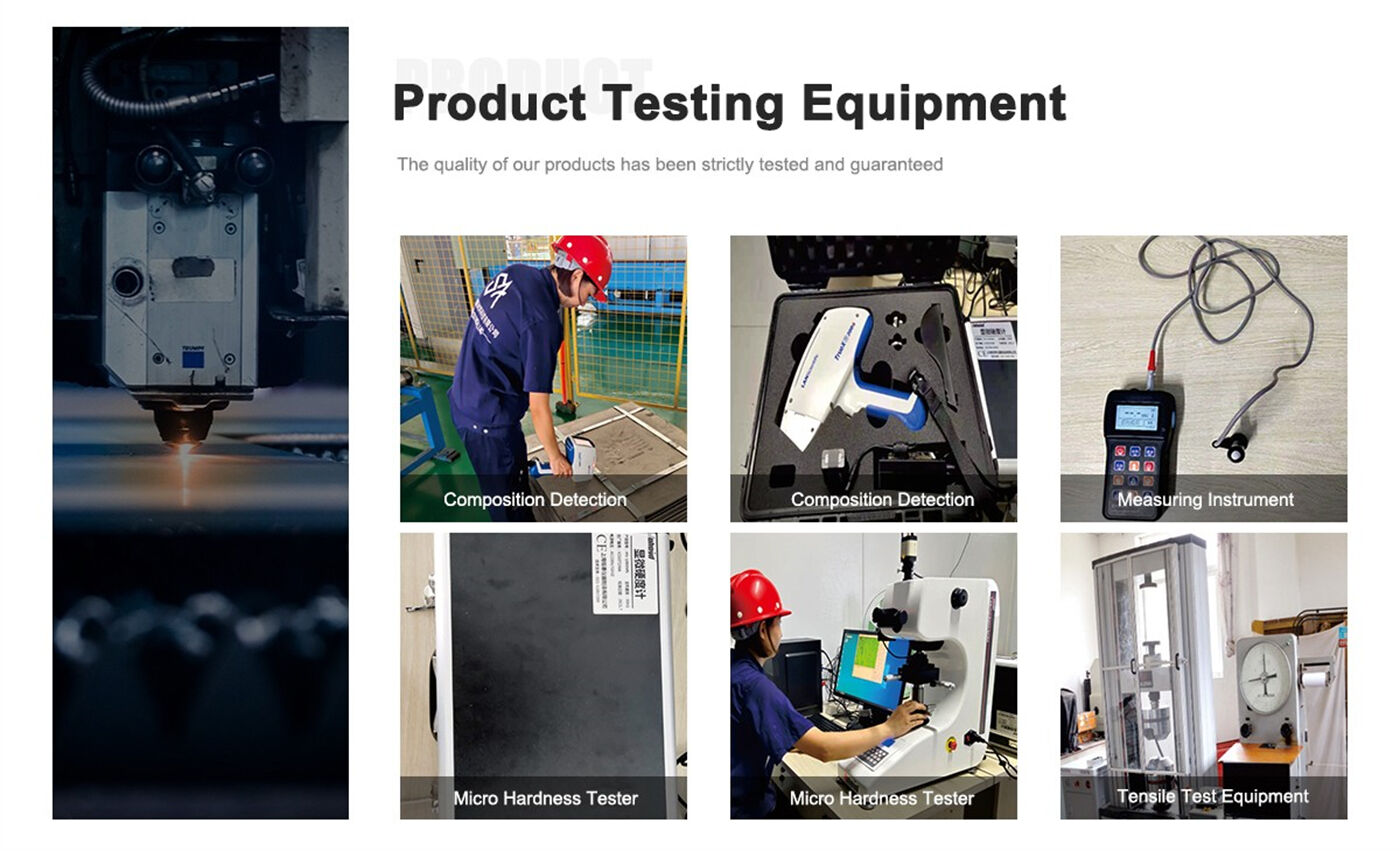

Certified High-Quality Alloy – Complies with AWS, ASTM, and ISO standards.

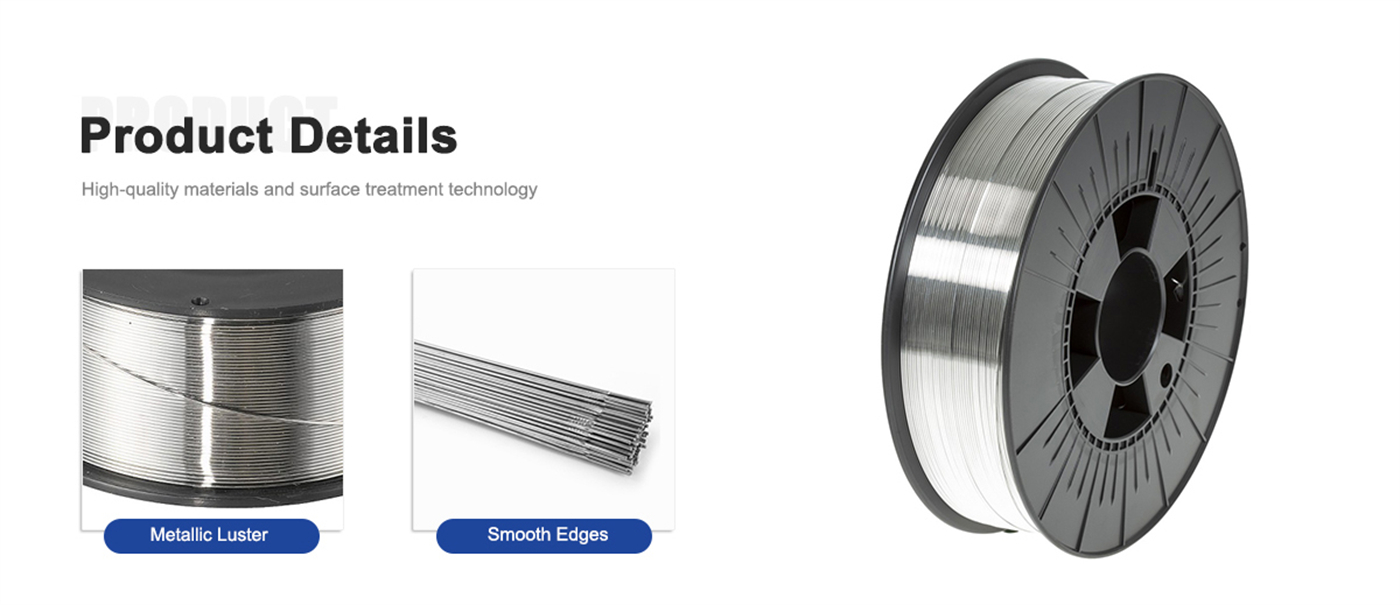

Custom Sizes & Packaging – Available in spools, coils, and custom-cut lengths.

Fast & Reliable Global Delivery – Ensuring on-time supply for urgent projects.

Guaranteed Stock Availability – Always ready for large-scale industrial applications.

Order ERNiCrMo-4 (C-276) Welding Wire Today – Special Offers Available!

Looking for cost-effective welding solutions for chemical and power plants? Take advantage of our special offers and bulk discounts! Contact us today for customized orders and fast shipping.

| Item | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

| C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

| Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

| Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

| P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

| S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

| Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

| Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | rest | rest | 0.25 |

| Ni | ≥58 | rest | rest | rest | ≥67 | 62-69 | 30-32 | ≥93 |

| Co | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

| Al | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

| Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

| Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

| Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2.0-3.0 | N/A | N/A | N/A |

| Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

| V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

| W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

| Rest | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

| Nickel and Nickel Alloy Welding Wire | |

| Product Model (AWS) | Application |

| ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

| ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

| ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

| ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

| ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

| ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

| ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

| ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

| ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

| ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

| ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

| ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |