Поръчайте ERNiCrMo-4 (C-276) Сварваща жица по оптови цени – Бърза доставка

- Преглед

- Препоръчани продукти

Въведение в ERNiCrMo-4 (C-276) Сварлив Провод

Сварителната нишка ERNiCrMo-4 (C-276) е никел-хром-молибденова алой, разработена за високопроизводителни сварителни приложения в корозивни и високотемпературни среди. Позната си е с изключителната си корозионна устойчивост, механична сила и универсалност, тази алой намира широка употреба в индустриите като химическа обработка, морска, авиационна и енергогенерация.

Ние предлагаме висококачествена сварителна нишка ERNiCrMo-4 (C-276) по оптови цени, гарантирайки ефективни решения от гледна точка на цената, голями отстъпки при големи поръчки и бърза международна доставка. Дали я нуждаете за сваряване на тръби, топлообменици или налягането на резервоари, нашата сварителна нишка осигурява превъзходна сваряемост и продължителна издръжливост.

Преглед на материал: Свойства на сварващата жица ERNiCrMo-4 (C-276)

ERNiCrMo-4 (C-276), познат още като Hastelloy® C-276, е никелова сплавена основа, която предлага:

Превъзходна корозионна устойчивост – Отлична устойчивост към окисляване, точкова корозия, интерстициална корозия и корозия при стресови трескания.

Силна на високи температури – Функционира изключително добре при температури до 1093°C (2000°F).

Изключителна свариваемост – Минимален горещ треск и висококачествено фузионно сваряване.

Устойчивост към агресивни химикали – Съпротива се на киселинни и хлоридосадржащи среди.

Висока механична твърдост – Идеална за приложения при високи напрежения и високо налягане.

Благодарение на тези свойства, сварващата нижда ERNiCrMo-4 се използва широко в критични сварващи проекти, които изискват екстремна прочност и устойчивост.

Индустрийни стандарти и спецификации

Нашата сварваща нижда ERNiCrMo-4 (C-276) се производи според строги индустриални стандарти, гарантирайки надежден перформанс при изискващи условия.

Стандартна спецификация

AWS A5.14 ERNiCrMo-4

UNS номер N10276

ASTM стандарт ASTM B574, ASTM B575

ISO стандарт ISO 18274: NiCr15Mo16Fe6W4

Тези сертификати гарантират, че нашата сварваща нижда отговаря на най-високите качествени изисквания за индустриално използване.

Приложения на ERNiCrMo-4 (C-276) дъска за сваряване

1. Химикална и нефтехимикална индустрия

Теплообменици и натискни съдове – Осигуряват устойчивост към корозията в киселични и високонатискни среди.

Транспортни линии и съдове за съхранение – Гарантират продължителна ефективност при агресивна химическа обработка.

2. Морска и офшорна инженерия

Корабостроителство и системи за морска вода – Предотвратява корозията в солена вода и морски условия.

Оборудване за проучване на нефть и газ – Използва се за подводни трасета и платформи за офшорно буравене.

3. Авиационна и енергогенерация

Газови турбини и реактивни двигатели – Съпротивлява се на окислението при високи температури и екстремните механични напрежения.

Атомни електроцентрали – Осигурява устойчивост към радиацията и топлината за компонентите на атомния реактор.

4. Производство на храна и фармацевтични продукти

Санитарни трасета и съдове за съхранение – Поддържа хигиенични и без контаминация процеси.

Оборудване за термична обработка – Предлага надежден сварлив при високи температури.

Защо да изберете нашата ERNiCrMo-4 (C-276) сварваща нишка?

Оптови цени директно от фабриката – Получавайте най-добри пазарни цени за големи поръчки.

Сертифициран висококачествен сплав – Отговаря на стандартите AWS, ASTM и ISO на индустрията.

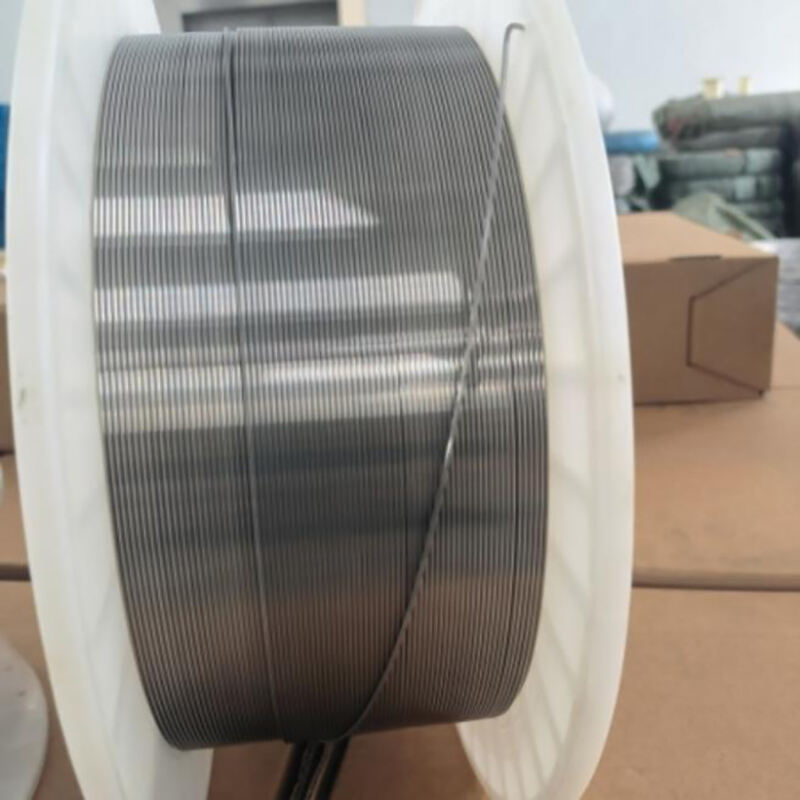

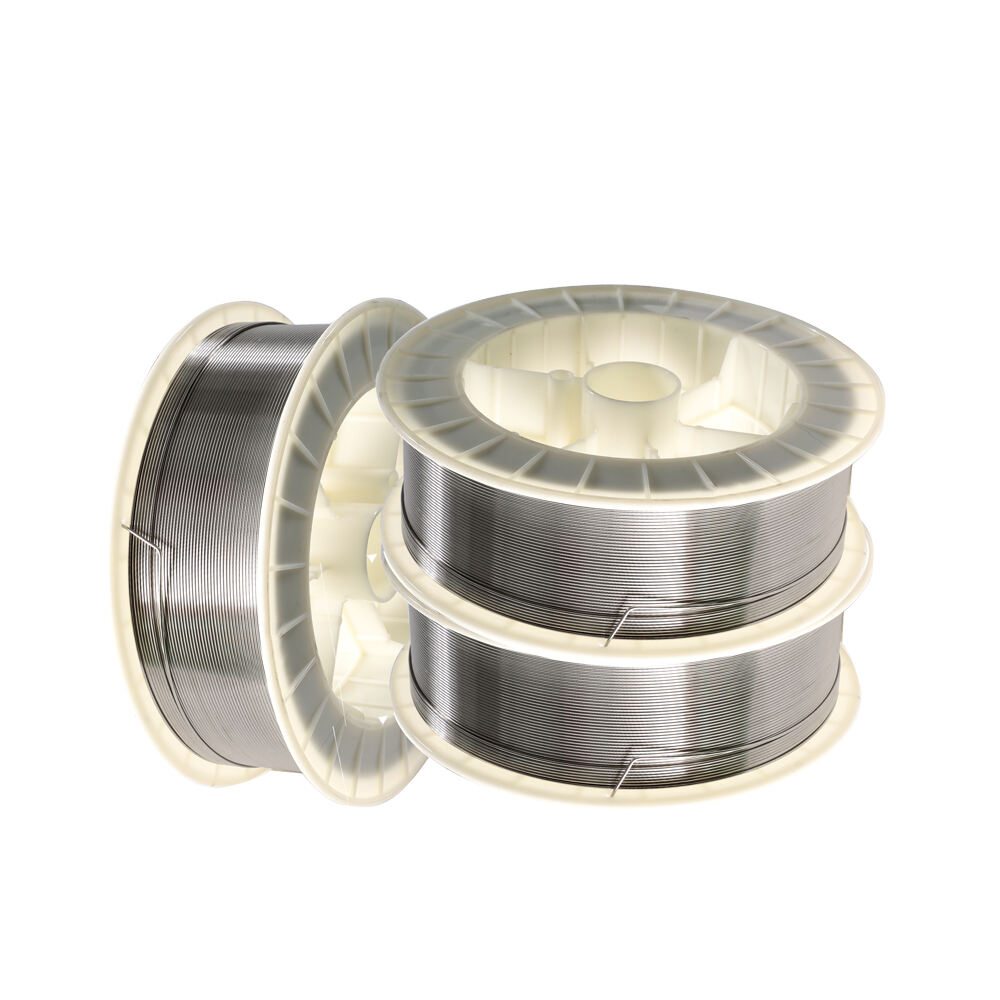

Персонални размери и упаковка – Доступни в бобини, спираловидни обвивки и отсечени дължини.

Бърза международна доставка – Бързо пратване за срочни индустриални сварващи проекти.

Надежден логистически верига – Гарантирана постоянна наличност на склад.

Получете оферта за ERNiCrMo-4 (C-276) сварващ проводник днес!

Търсите висококачествен ERNiCrMo-4 (C-276) сварващ проводник по оптови цени? Свържете се с нас днес за голями отстъпки, персонални поръчки и бърза доставка.