Сплав от никъл Monel K500 – Най-добър материал за аерокосмически и нефтеноразработващи приложения

Предлагаме заводски директни цени и специални отстъпки за групови поръчки. Дали имате нужда от малки или големи количества, продуктите ни се доставят бързо, за да гарантираме надежден доставчик за индустриални проекти по цял свят.

- Преглед

- Спецификация

- Приложения

- Често задавани въпроси

- Препоръчани продукти

-

Висока твърдост и твърдост: Подобрява се чрез твърдяване посредством кристалите.

-

Изключителна устойчивост към корозията: Ефективна в морски, киселинни и алкални среди.

-

Отличен перформанс при високи температури: Запазва механичните си свойства до 480°C (900°F).

-

Ниска магнитна проницаемост: Незаменима за приложения, изискващи минимално магнитно вмешване.

-

Превъзходна устойчивост към износ и умора: Подходяща за продължително използване при екстремни условия.

-

Авиационна индустрия:

-

Лопатки за турбини и компоненти на двигателя

-

Закрепители и части от ходовата система

-

Структурни компоненти в самолети и космически апарати

-

-

Нефтен и газов индустрия:

-

Бурови компоненти като насосни валове и клапанни стъбчи

-

Контролни линии и подземни сигнализаторни клапани

-

Тубации иconductors pipeline разположени в корозивни среди

-

-

Морска инженерия:

-

Валове за винтове и компоненти на помпи за морска вода

-

Подводни и военноморски компоненти

-

Завивки за офшорни конструкции

-

-

Химикофармацевтична индустрия:

-

Топлообменици и реакционни съдове

-

Тръби и фитингове при силно корозивни условия

-

Помпи и кранове, обработващи агресивни химикали

-

-

ASTM B865 - Стандартна спецификация за стержове, пръти и формувания.

-

AMS 4676 - Авиационен стандарт за високоперформантни приложения.

-

ASME SB865 - Стандарти за използване в тласти и системи за канализация.

-

Плавене и сплавяне: Високочисти сировини се плавят в електрически дугови или вакуумни индукционни печи.

-

Топло и студено обработване: Сплавът подлежи на ролирање, екструзия или формуване, за да се достигне желаният облик и размер.

-

Термична обработка (Стареене): Материалът е подложен на растворително отопяване и след това се старее за оптимизиране на неговата сила.

-

Прецезна обработка и финиш: Включва връщане, шлифуване и полирване, за да се изпълнят точните спецификации.

-

Контрол на качеството и инспекция: Провежда неинвазивни тестове (NDT), химически анализи и проверка на механичните свойства.

-

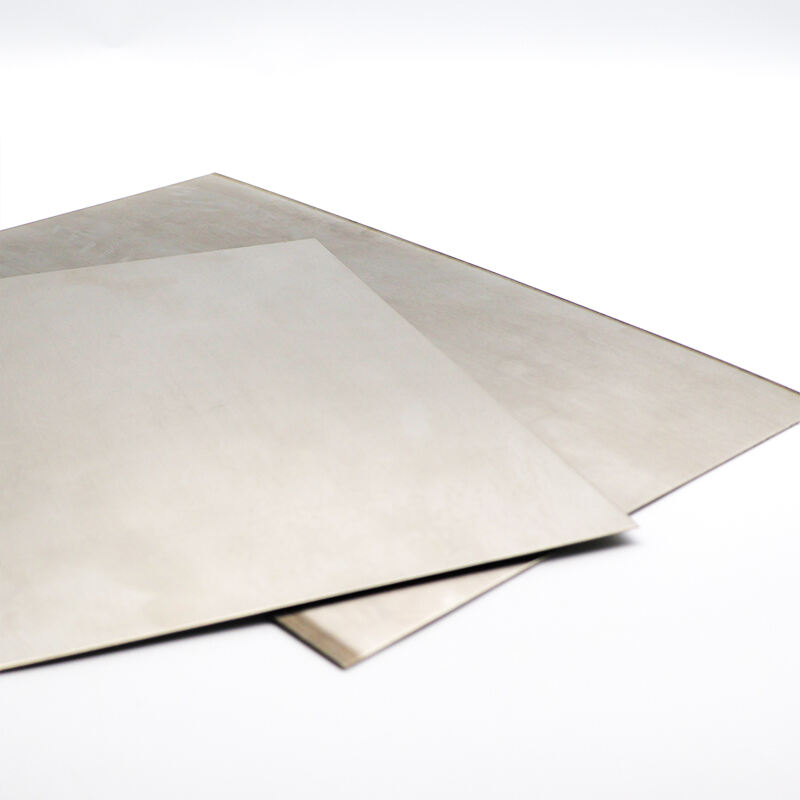

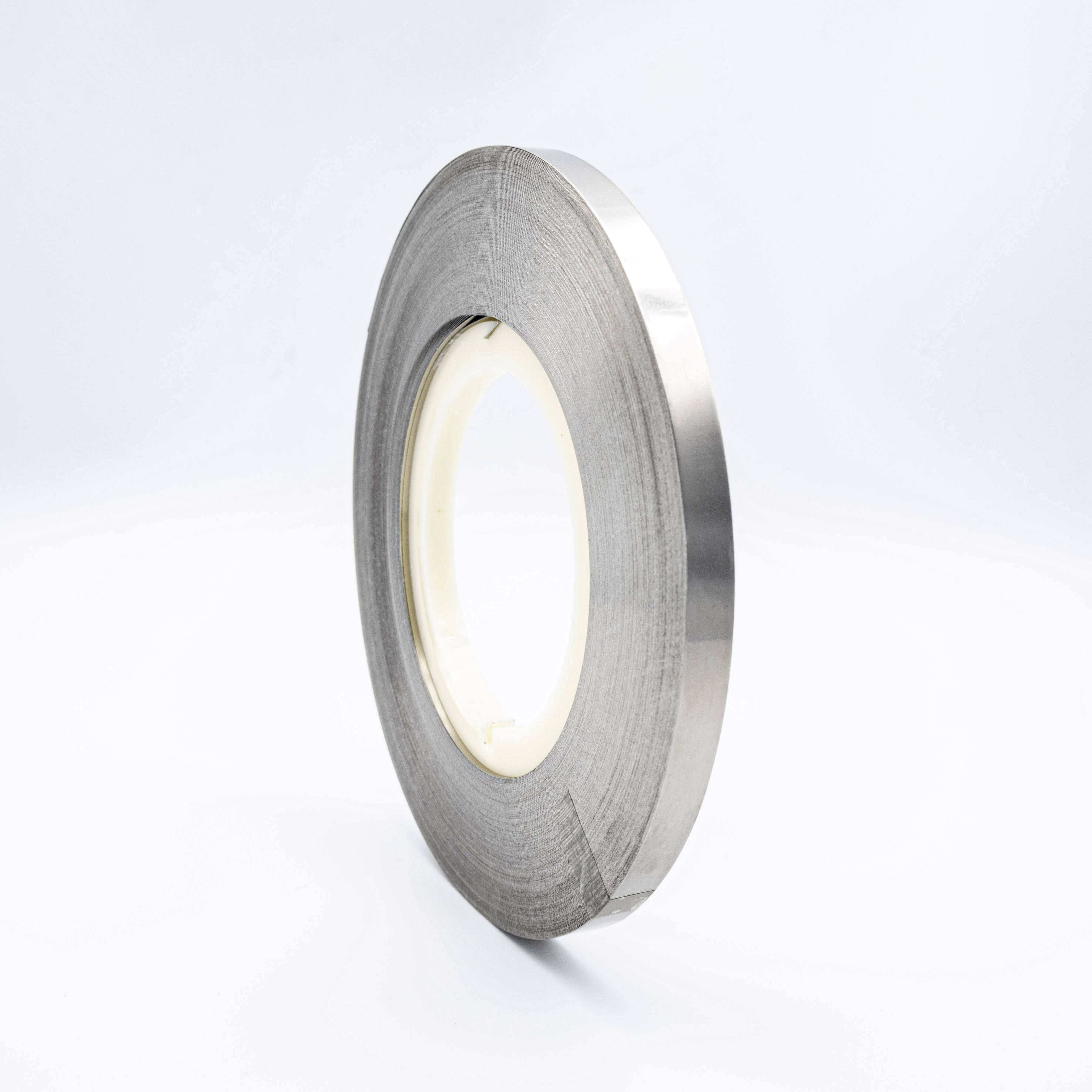

Персонализирани размери и толщини: Доступни в различни диаметри, толщини и дължини.

-

Опции за термична обработка: Предоставя се във вид отоплен, хладно теглен или стареен материал.

-

Повърхностни завършвания: Сиящи, полирани или шлифувани повърхности, адаптираните според изисканията на приложението.

-

Сертификати и съответствие: Предоставят се със заводски протоколи за испитване (MTR), сертификати за трета страна и съответствие на стандарти ASTM/ASME/AMS.

Monel K500 е високопроизводителен никелов сплав, който kombinira отличната корозионна устойчивост на Monel 400 с повишена твърдост и прочност. Тази подобряване се постига чрез добавяне на алуминий и титан, следвано от процес на твърдяване при стареене. Благодарение на своите превъзходни механични свойства и устойчивост към стресни среди, Monel K500 намира широка приложение в аерокосмическата и нефтен индустрия.

Състав и свойства на материал

Monel K500 главно се състои от никел (63% минимум) и мед (27-33%), с малки количества алуминий (2.3-3.15%), титан (0.35-0.85%), желязо (до 2%) и магнезий (до 1.5%). Сплавът е добре известен поради следните характеристики:

Приложения на сплав Monel K500

Благодарение на своите отлични свойства, Monel K500 намира широкото си приложение в индустриите, които изискват надеждност и дълговечност:

Общи градации и стандарти

Алой Monel K500 е наличен в различни градации, отговарящи на международни стандарти, което гарантира висока надеждност и качествен контрол.

Производствен процес

Производството на Monel K500 включва няколко критични стъпки, които подобряват неговите механични и химични свойства:

Изпълнение на клиентските изисквания

Производителите предлагат персонализирани продукти от сплав Monel K500, за да отговорят на специфичните нужди на различните индустрии:

Често задавани въпроси:

Колко време отнема доставката?

Зависи от количеството на поръчката, 10-30 дни за малки поръчки. За големи поръчки е необходимо 60 дни.

Приемате ли производство по OEM/ODM?

Да! Приемаме производство по OEM/ODM. Можете да ни изпратите примерите или чертежите си.

Как контролирате качеството на продуктите си? Дали химическите свойства на продуктите отговарят на стандартите за качество?

С професионална екипаж за качество, напреднали планиране на продуктното качество, строга реализация и непрекъснато подобряване, ще издаваме сертификат за проверка на качеството на продукта, включително химически анализи.

Може ли вашата firma да предостави подробни технически данни и чертежи?

Да, можете. Казвайте ни какви продукти и приложения ви трябват, и ще ви изпратим подробни технически данни и чертежи за оценка и потвърждение.

Как обработвате услугите преди и след продажбата?

Имаме професионален бизнес екип, който ще работи един срещу един, за да защити нуждите ви за продукти, а ако имате въпроси, той може да ви ги отговори!

Мога ли да посетя фабриката ви преди да направя поръчка?

Да, добре дошъл да ни посетиш. Радваме се да имаме възможността да се запознаем.

Къде е вашето производствено база?

Произвеждаме продуктите си в Цзянсу, Китай и ги пратяме от Китай в страната ви възможно най-бързо, което обикновено зависи от изискванията за продукта и количеството.

Можете ли да изпратите примерки?

Да, можем.