Best ERNiCrMo-4 (C-276) Welding Wire for Oil & Gas Industry – Factory Supply

- Overview

- Recommended Products

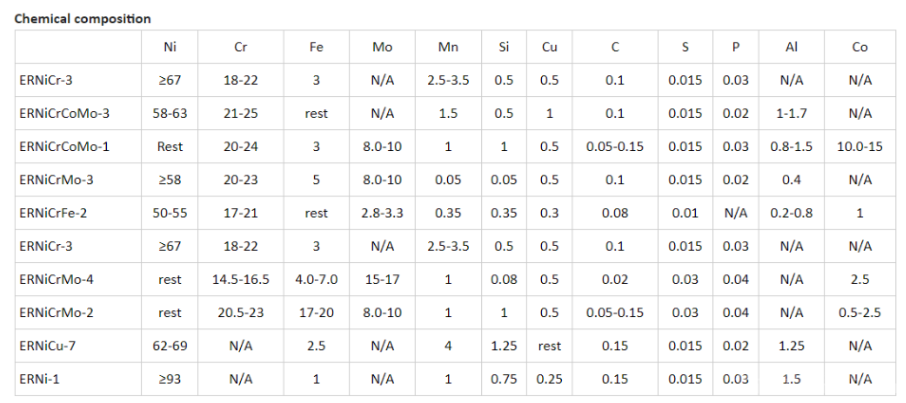

Introduction to ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 (C-276) welding wire, commonly known as Hastelloy® C-276, is a high-performance nickel-chromium-molybdenum alloy designed for extreme corrosion resistance and superior weldability. It is widely used in the oil & gas industry, where components must withstand harsh chemicals, high temperatures, and aggressive environments.

As a factory-direct supplier, we offer high-quality ERNiCrMo-4 welding wire with competitive pricing, bulk discounts, and global delivery. Our products are manufactured to strict industry standards, ensuring superior weld strength and long-term durability in demanding applications.

Material Overview: Properties of ERNiCrMo-4 (C-276) Welding Wire

ERNiCrMo-4 is known for its exceptional mechanical and chemical properties, making it ideal for oil & gas applications that require high-strength and corrosion-resistant welds.

✔ Superior Corrosion Resistance – Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking in acidic and chloride-rich environments.

✔ High-Temperature Performance – Maintains mechanical integrity in temperatures up to 1093°C (2000°F).

✔ Exceptional Weldability – Produces clean, defect-free welds with minimal hot cracking.

✔ Resistance to Sulfide Stress Cracking – Ideal for sour gas (H₂S) environments in oil refineries and offshore drilling.

✔ High Strength & Toughness – Withstands high-pressure and heavy-duty operations.

These features make ERNiCrMo-4 welding wire essential for ensuring durability and reliability in oil & gas applications.

Industry Standards & Specifications

Our ERNiCrMo-4 (C-276) welding wire meets international standards for quality and performance, ensuring compatibility with critical applications.

Standard Specification

AWS A5.14 ERNiCrMo-4

UNS Number N10276

ASTM Standard ASTM B574, ASTM B575

ISO Standard ISO 18274: NiCr15Mo16Fe6W4

These certifications guarantee that our welding wire is engineered for high-performance welding in the oil & gas industry.

Applications of ERNiCrMo-4 (C-276) Welding Wire in Oil & Gas Industry

1. Offshore Drilling & Subsea Pipelines

Used for welding underwater pipelines, risers, and offshore platforms.

Provides resistance to seawater corrosion and extreme pressure conditions.

2. Refinery & Petrochemical Processing Equipment

Ensures durable welds in crude oil processing units, heat exchangers, and storage tanks.

Withstands acidic and high-sulfur environments in refineries.

3. Gas Processing & LNG Facilities

Ideal for welding cryogenic storage tanks and natural gas pipelines.

Prevents material degradation in high-pressure gas applications.

4. Downhole & Wellhead Equipment

Used for casing, tubing, and drilling tools in high-temperature, high-pressure oil wells.

Resistant to hydrogen sulfide (H₂S) and other corrosive gases.

5. FPSO & Marine Applications

Provides corrosion-resistant welds for floating production storage and offloading (FPSO) units.

Maintains structural integrity in saline and high-humidity environments.

Why Choose Our ERNiCrMo-4 (C-276) Welding Wire?

Factory-Direct Wholesale Pricing – Competitive rates for bulk orders and OEM customers.

Certified High-Quality Alloy – Manufactured to AWS, ASTM, and ISO standards.

Custom Sizes & Packaging – Available in spools, coils, and cut-to-length options.

Fast Global Delivery – Quick shipping to oil & gas companies worldwide.

Reliable Supply Chain – Ensuring consistent stock availability for industrial projects.

Order ERNiCrMo-4 (C-276) Welding Wire for Oil & Gas Industry Today!

Need high-quality welding wire for oil rigs, refineries, and offshore drilling projects? Contact us today for bulk pricing, custom orders, and fast shipping.

Q:I have sent the RFQ, when can I expect a reply?

A:We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price, please send the message on trade management or call us directly.

Q:How long is the delivery time?

A:It depends on the order quantity ,Usually it takes about 20-30 days.

Q:Do you accept OEM/ODM manufacturing?

A:Yes! We do accept OEM/ODMmanufacturing. You could give us your samples or drawings.

Q:Can you send me your catalogue?

A:Yes, please contact us.We can share with our catalogue for you by email.

Q:How to control the products quality in your company?

A:With professional quality team, advanced product quality planning, strict implementation, continuous improvement, the quality of our products is well controlled and consistent.

Q:Can you provide detailed technical data and drawing?

A:Yes, we can. Please tell us which product you need and the applications, we will send the detailed technical data and drawing to you for your evaluation and confirm.

Q:How do you handle pre-sales and post-sales?

A:We have a professional business team that will work one-on-one with you to protect your product needs, and if you have any questions, he can answer them for you!

Q:Can I visit your factory before we place an order?

A:Yes, you are welcome to visit our factory. We are very pleased if we have the chance to know more about each other.

Q:Where can I find up-to-date information about the company?

A:You can check our news or blog for information about our company.