أطقم هاستيلوي C-276 Premium – مقاومة للتآكل وقوية للغاية

نقدم أسعارًا مباشرة من المصنع وخصومات خاصة للطلبات بالجملة. سواء كنت بحاجة إلى كميات صغيرة أو كبيرة، يتم شحن منتجاتنا بسرعة لضمان توريد موثوق للمشاريع الصناعية حول العالم.

- ملخص

- المواصفات

- التطبيقات

- أسئلة شائعة

- المنتجات الموصى بها

مقدمة حول ألواح هاستيلوي C-276

هاستيلوي C-276 هو سبيكة نيكل-موليبدينوم-كروم عالية الأداء معروفة بمقاومتها الاستثنائية للتآكل، خاصة في البيئات العدوانية للغاية. يتم استخدامها على نطاق واسع في الصناعات التي تتعرض فيها المواد لدرجات حرارة شديدة، والمواد المؤكسدة والمختزلة، والظروف الحمضية بشكل شائع. تُعتبر ألواح هاستيلوي C-276 مثالية للتطبيقات التي تتطلب قوة عالية، ومتانة، ومقاومة للتآكل النقطي، والتشقق التآكلي تحت التوتر، والتآكل الشقوق.

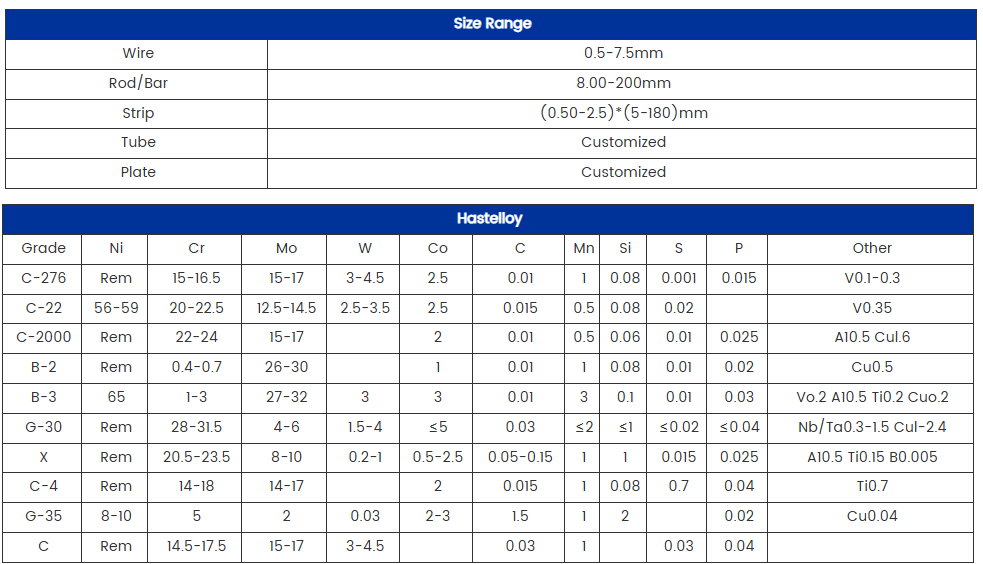

التكوين الكيميائي والدرجات

يُصنَّف حلاloy C-276 تحت معيار UNS N10276 ويتوافق مع العديد من المواصفات الصناعية مثل ASTM B575 و ASME SB575. يتكوّن السبيكة بشكل أساسي من:

النيكل (Ni): 57% كحد أدنى - يوفر مقاومة فائقة للتآكل

الموليبدينوم (Mo): 15-17% - يعزز مقاومة التآكل الموضعي

الكروم (Cr): 14.5-16.5% - يحسن مقاومة الأكسدة

الحديد (Fe): 4-7% - يضيف القوة الهيكلية

الكوبلت (Co): 2.5% كحد أقصى

العناصر الأخرى: التنغستن (W)، الكربون (C)، السيليكون (Si)، والمanganese (Mn) بكميات متحكم فيها

عملية التصنيع

تُنتَج أوراق Hastelloy C-276 باستخدام تقنيات ميتالورجية متقدمة لضمان أداء عالي الجودة. تشمل عملية التصنيع:

الذوبان والتسبك: يتم إذابة المواد الخام ذات النقاء العالي في فرن إندوكتيوي شاغر.

التدوير الساخن والبارد: يتم معالجة السبيكة إلى ألواح من خلال سلسلة من تقنيات التدوير الساخنة والباردة للحصول على السمك والخصائص الميكانيكية المرغوبة.

المعالجة الحرارية والتبريد: تخضع الألواح للتبريد الحلالي عند حوالي 1100-1150°C (2012-2102°F)، يتبعها تبريد سريع للحفاظ على مقاومة التآكل.

إنهاء السطح والتحكم في الجودة: يتم معالجة الألواح النهائية بالتشريب أو التلميع أو الطلاء لتحسين المتانة وتُفحص عن وجود عيوب قبل الشحن.

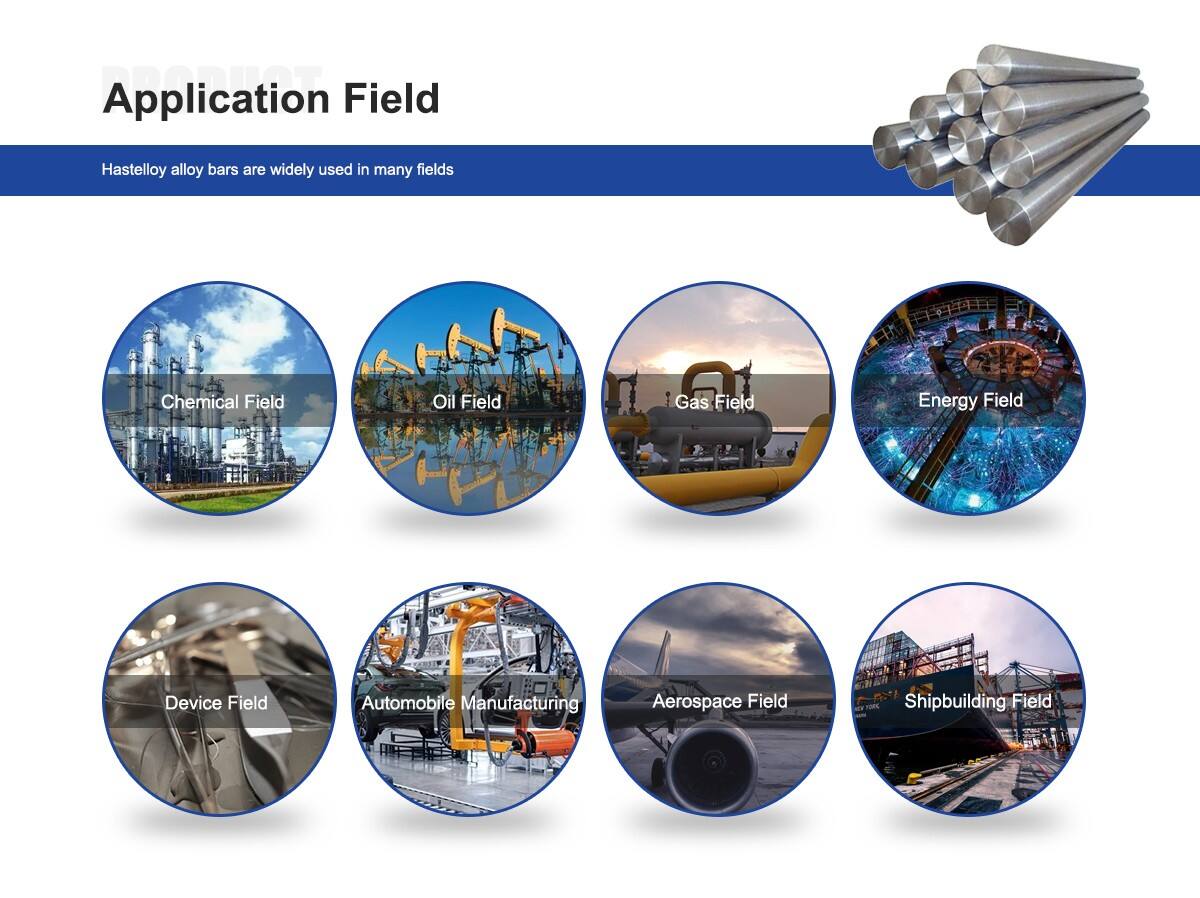

تطبيقات ألواح هاستيلوي C-276

بسبب مقاومتها المتميزة للتآكل، تُستخدم ألواح هاستيلوي C-276 بشكل واسع في الصناعات التالية:

معالجة الكيميائيات: تُستخدم في المفاعلات ومبادلات الحرارة والمكثفات التي تعامل أحماض قوية (مثل حمض الهيدروكلوريك وحمض الكبريت).

البحري والبحري الخارجي: مثالية لمصانع تحلية المياه البحرية ومنصات النفط والغاز وأجزاء السفن المعرضة للتآكل الناتج عن مياه البحر.

إنتاج الطاقة: تُستخدم في أنظمة إزالة الكبريت من غاز العادم (FGD) وأجزاء المرجل في محطات الطاقة.

صناعة الأدوية والغذاء: تُستخدم في معدات المعالجة الصحية والعالية النقاء بسبب مقاومتها للتلوث.

الفضاء والدفاع: مناسبة للمكونات المحركية العاملة بدرجات حرارة عالية وللمواد الهيكلية في البيئات القاسية.

لماذا تختار أوراق هاستيلوي C-276 الخاصة بنا؟

مقاومة للتآكل: تصمد أمام الظروف الحمضية والأكسدة القاسية.

ثبات درجة الحرارة العالية: تعمل بشكل جيد في ظروف الحرارة الشديدة حتى 1000°C (1832°F).

قوة ميكانيكية متفوقة: القوة المقاومة والشد العالي يضمنان المتانة على المدى الطويل.

أحجام وسماكات مخصصة: متاحة بأبعاد مختلفة لتلبية احتياجات المشاريع المحددة.

أسعار مباشرة من المصنع: نقدم أسعار تنافسية للطلبات bulk مع شحن سريع عالميًا.

اطلب أوراق هاستيلوي C-276 اليوم

إذا كنت تبحث عن أوراق هاستيلوي C-276 ذات جودة ممتازة بمقاومة تآكل ممتازة وقوة ميكانيكية، فإننا مورّدك الموثوق. تواصل معنا اليوم للحصول على أفضل الأسعار، خصومات الدفع الجماعي، وخدمات OEM لتلبية احتياجاتك الصناعية.

الأسئلة الشائعة:

كم المدة التي يستغرقها التسليم؟

يعتمد ذلك على كمية الطلب، 10-30 يومًا للطلبات الصغيرة. أما بالنسبة للطلبات الكبيرة، يستغرق الأمر 60 يومًا.

هل تقبلون الإنتاج الخاص بعلامات تجارية أوسع (OEM/ODM)؟

نعم! نحن نقبل الإنتاج الخاص بعلامات تجارية أوسع (OEM/ODM). يمكنك إرسال العينات أو الرسومات لنا.

كيف تضمنون جودة منتجاتكم؟ هل الخصائص الكيميائية للمنتجات تلبي معايير الجودة؟

مع فريق متخصص في الجودة، والتخطيط المتقدم لجودة المنتج، والتنفيذ الصارم والتحسين المستمر، سنصدر شهادة فحص جودة المنتج، بما في ذلك تقرير التحليل الكيميائي.

هل يمكن لشركتك تقديم البيانات الفنية التفصيلية والرسومات؟

نعم، يمكنك ذلك. يرجى إخبارنا بالمنتجات والتطبيقات التي تحتاجها، وسنرسل لك البيانات الفنية التفصيلية والرسومات لتقييمها وتأكيدك عليها.

كيف تتعاملون مع الخدمات قبل البيع وبعده؟

لدينا فريق أعمال محترف سيتعاون معك بشكل مباشر لحماية احتياجات منتجاتك، وإذا كان لديك أي أسئلة، يمكنه الإجابة عليها لك!

هل يمكنني زيارة مصنعكم قبل تقديم الطلب؟

نعم، أهلاً بكم لزيارة مصنعنا. نحن سعداء بالحصول على فرصة للتعرف على بعضنا البعض.

أين يقع قاعدة إنتاجكم؟

نقوم بتصنيع منتجاتنا في جيانغسو، الصين ونرسلها من الصين إلى بلدكم في أقرب وقت ممكن، وهو عادة ما يعتمد على متطلبات المنتج وكميته.

هل يمكنكم إرسال عينات؟

نعم، يمكننا ذلك.