Aerospace-Approved Inconel 718 Spring Wire for High-Load Mechanical Components

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

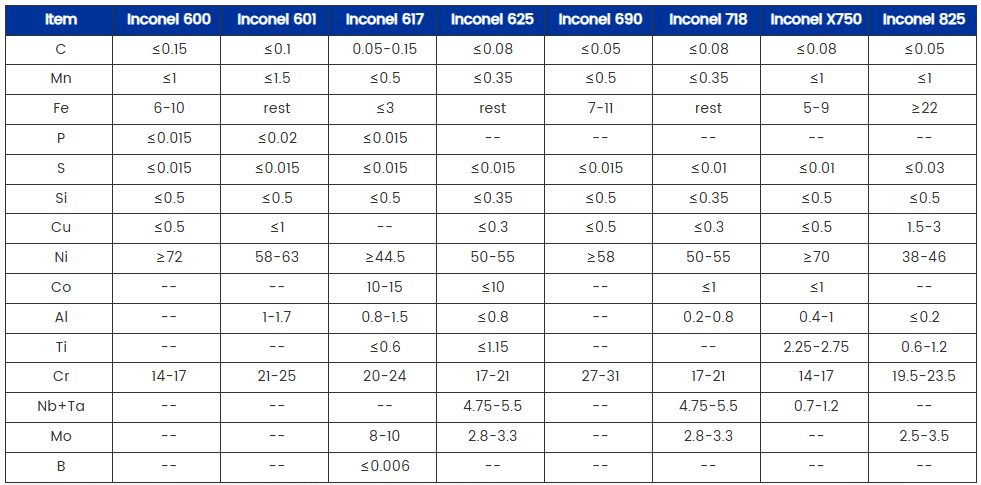

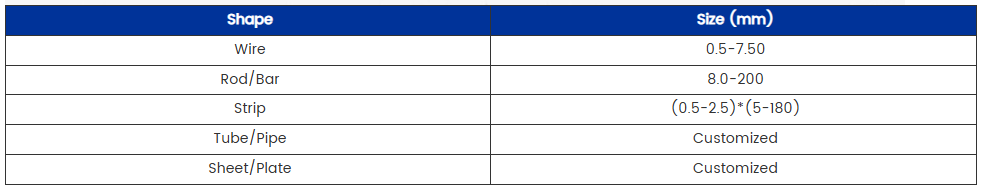

- Specification

- Applications

- FAQs

- Recommended Products

-

Exceptional Strength-to-Weight Ratio: High tensile strength (up to 180 ksi) and fatigue resistance ensure reliability under repetitive stress.

-

Thermal Stability: Retains mechanical properties from cryogenic temperatures up to 700°C (1300°F), making it ideal for jet engines and high-speed flight systems.

-

Corrosion & Oxidation Resistance: Chromium and niobium additions provide resistance to oxidation, sulfidation, and chloride-induced stress corrosion cracking.

-

Creep Resistance: Maintains dimensional stability under prolonged high-stress conditions, crucial for long-duration flights.

-

Aerospace Certification Compliance: Meets AMS 5698, AMS 5662, and ASTM B637 standards, ensuring material consistency for critical flight components.

-

Turbine Blade Retainers – Withstands centrifugal forces and thermal cycling.

-

Combustion Chamber Springs – Resists oxidation in high-temperature, high-pressure environments.

-

Shock Absorber Springs – Provides durability under dynamic loading during takeoff and landing.

-

Actuator Springs – Ensures precise control surface movement in extreme conditions.

-

Rocket Thrust Vector Control (TVC) Springs – Handles extreme thermal gradients and mechanical stress.

-

Satellite Deployment Mechanisms – Offers reliability in vacuum and radiation-exposed environments.

-

High-Pressure Valve Springs – Maintains sealing integrity in fuel injection and hydraulic control systems.

-

Next-Gen Aircraft Development – Increased production of commercial jets (Boeing 787, Airbus A350) and military aircraft (F-35) demands high-performance materials.

-

Additive Manufacturing Integration – 3D-printed Inconel 718 components allow complex geometries with reduced weight.

-

Sustainability & Fuel Efficiency – Lightweight yet durable alloys help reduce aircraft weight, lowering fuel consumption.

-

Space Exploration Growth – Private space companies (SpaceX, Blue Origin) require reliable materials for reusable rockets and satellites.

-

Stringent Safety Regulations – FAA and EASA certifications push manufacturers toward proven, high-reliability alloys like Inconel 718.

In the demanding world of aerospace engineering, materials must withstand extreme mechanical loads, temperature fluctuations, and corrosive environments while maintaining structural integrity. Inconel 718, a nickel-chromium superalloy, has emerged as a premier choice for high-performance spring wire in critical aerospace applications. This article examines the material properties of aerospace-approved Inconel 718 spring wire, its key applications, and the industry trends driving its adoption.

Material Properties and Performance Advantages

Inconel 718 is specifically engineered to meet the stringent requirements of aerospace components, offering:

Key Aerospace Applications

Aerospace-approved Inconel 718 spring wire is widely used in:

1. Jet Engine Components

2. Landing Gear & Flight Control Systems

3. Spacecraft & Hypersonic Systems

4. Fuel & Hydraulic Systems

Industry Trends Driving Demand

Several key factors are accelerating the use of Inconel 718 spring wire in aerospace:

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.