4J45 Alloy Sheets for Precision Manufacturing in Medical Devices and Aerospace

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

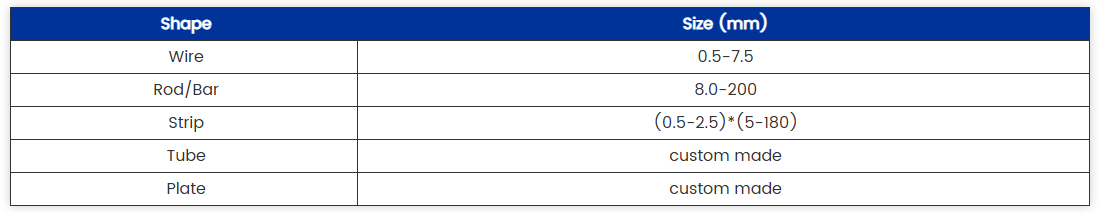

- Specification

- About Us

- FAQs

- Recommended Products

- Surgical Instruments: The high strength and corrosion resistance of 4J45 alloy make it ideal for manufacturing scalpels, forceps, and precision medical tools.

- Implantable Devices: The alloy’s low expansion coefficient ensures stability in bone plates, prosthetic components, and orthopedic implants.

- MRI-Compatible Components: Due to its non-magnetic properties, 4J45 alloy is used in medical equipment that operates in strong magnetic fields, such as MRI scanners and diagnostic tools.

- Precision Engine Components: Used in jet engine parts, turbine blades, and exhaust systems, where resistance to high temperatures is crucial.

- Structural Elements: The lightweight yet strong nature of 4J45 alloy contributes to aircraft frames, control systems, and fuselage reinforcements, improving fuel efficiency and structural integrity.

- Satellite and Spacecraft Applications: Due to its thermal stability and dimensional accuracy, 4J45 alloy is used in satellite housings, antenna components, and aerospace sensors, ensuring reliability in extreme conditions.

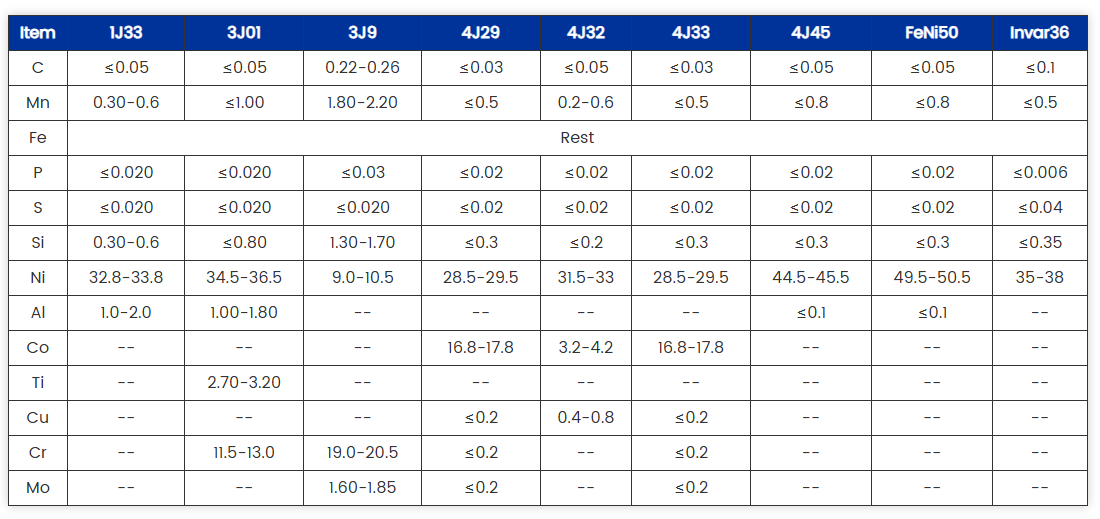

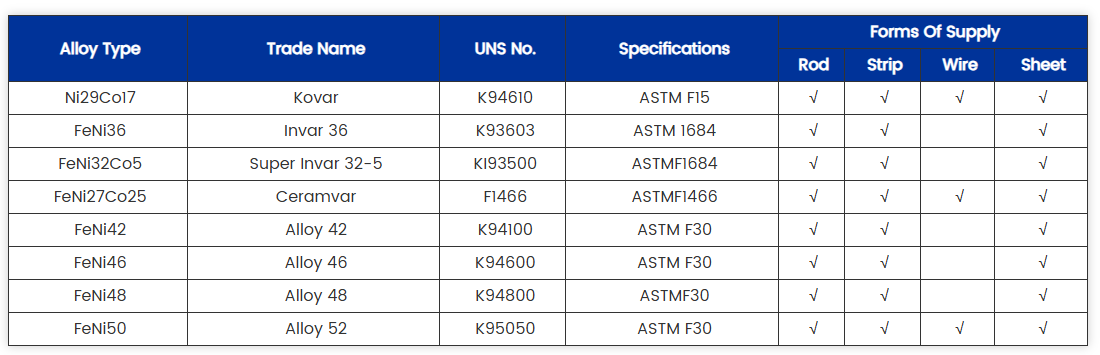

4J45 alloy is a specialized iron-nickel-cobalt alloy designed for applications requiring high precision, thermal stability, and superior mechanical properties. With its unique composition, 4J45 alloy exhibits low thermal expansion, excellent corrosion resistance, and high strength, making it ideal for industries where accuracy and reliability are critical.

In the medical and aerospace sectors, the demand for materials that offer dimensional stability, biocompatibility, and resistance to extreme environments is continuously increasing. 4J45 alloy sheets provide an excellent solution for these industries, ensuring the long-term durability and precision of high-performance components.

Applications of 4J45 Alloy Sheets

1. Medical Device Manufacturing

The medical field requires materials that are not only highly durable but also biocompatible and resistant to sterilization processes. 4J45 alloy sheets are widely used in:

2. Aerospace Engineering

The aerospace industry relies on materials that can withstand high temperatures, mechanical stress, and environmental challenges. 4J45 alloy sheets are essential in:

3. Precision Instrumentation

4J45 alloy sheets are widely used in optical instruments, semiconductor manufacturing, and high-precision measurement tools, where thermal expansion control is crucial to maintaining accurate readings.

User Demands and Requirements

1. High Precision and Dimensional Stability

Industries such as medical technology and aerospace engineering require materials with tight tolerances and minimal thermal expansion to ensure that components remain accurate and functional under different temperature conditions. 4J45 alloy sheets meet these requirements by offering consistent performance in precision manufacturing.

2. Corrosion and Oxidation Resistance

Medical and aerospace applications often expose materials to harsh environments, including sterilization chemicals, moisture, and high-altitude conditions. 4J45 alloy’s resistance to oxidation and corrosion ensures that critical components maintain their integrity over extended periods.

3. High Strength and Durability

In aircraft construction and medical implants, reliability is non-negotiable. 4J45 alloy sheets provide exceptional strength, ensuring that components can withstand mechanical stress without failure, even in high-pressure or high-vibration environments.

4. Compatibility with Advanced Manufacturing Technologies

Modern industries require materials that can be processed with precision machining, laser cutting, and advanced welding techniques. 4J45 alloy sheets are highly adaptable to these manufacturing processes, making them suitable for complex geometries and fine-tolerance applications.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

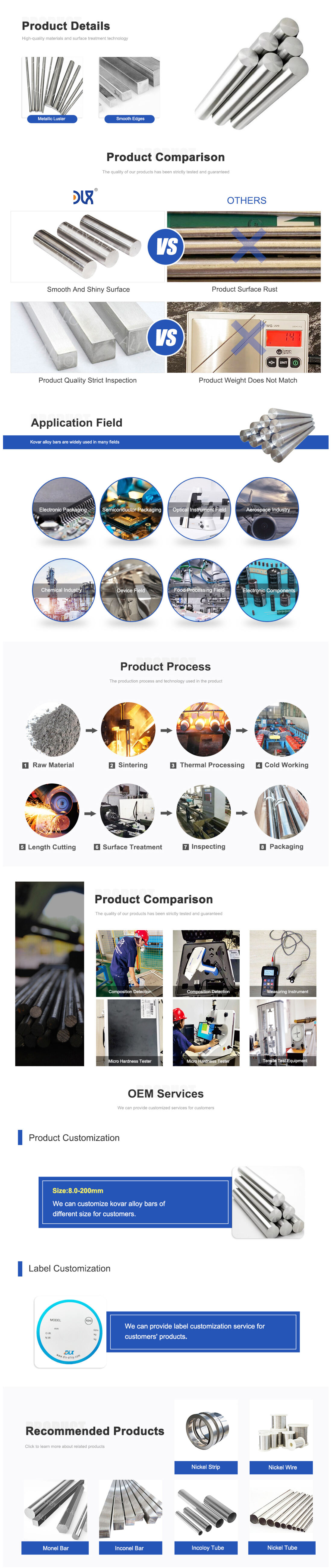

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.