3J9 Alloy Rods for Advanced Engineering Applications in Automotive and Aerospace

We offer factory direct pricing and special discounts on bulk orders. Whether you need small or large quantities, our products ship quickly to ensure a reliable supply for industrial projects worldwide. Click the button below to request a quote today!

- Overview

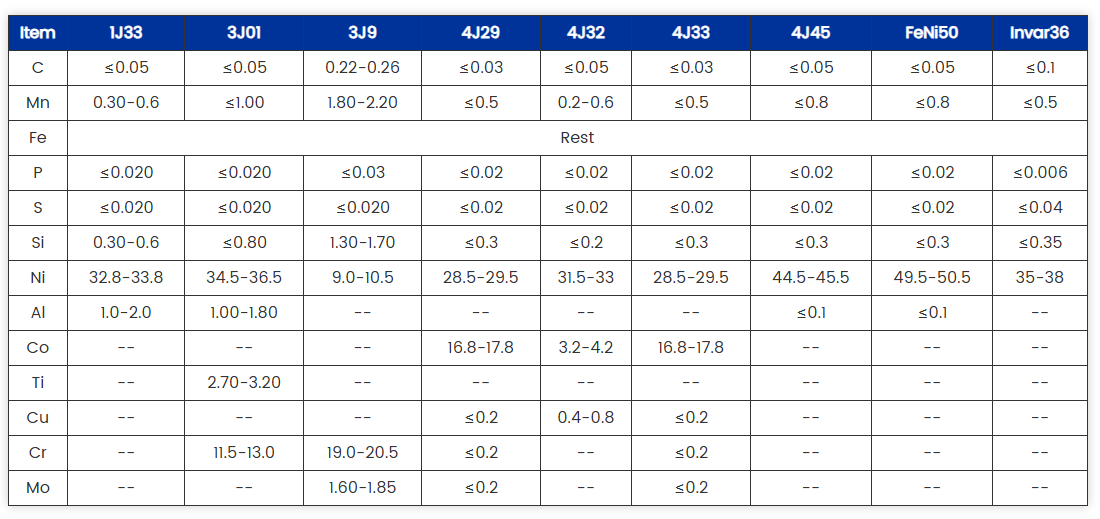

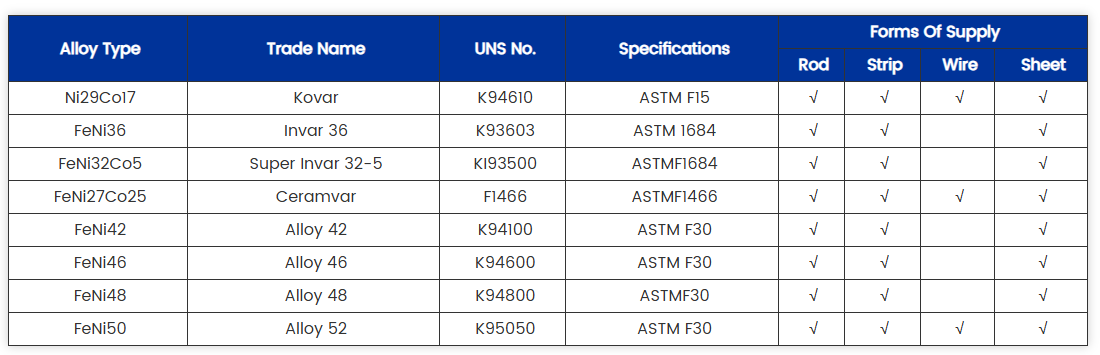

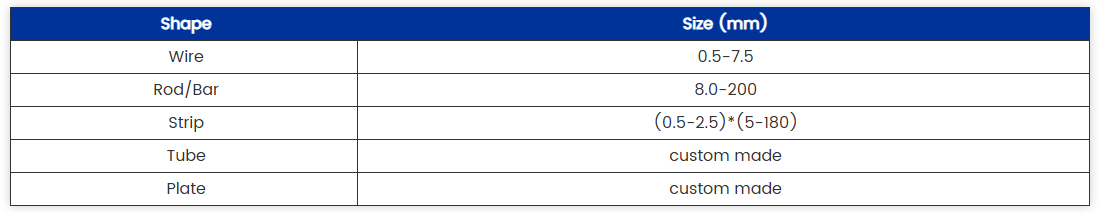

- Specification

- About Us

- FAQs

- Recommended Products

- High-Performance Engine Components: Used in valves, turbocharger shafts, and exhaust system parts, ensuring high durability under extreme heat and pressure.

- Transmission Systems: The wear resistance of 3J9 alloy helps extend the lifespan of gears, bearings, and drivetrain components.

- Electric Vehicle (EV) Battery Housings: With low thermal expansion, 3J9 alloy ensures the structural stability of EV battery enclosures, improving safety and efficiency.

- Aerospace Structural Components: Used in landing gear assemblies, support beams, and fuselage reinforcements, offering strength without excessive weight.

- Jet Engine and Turbine Parts: The alloy’s thermal resistance and oxidation protection make it suitable for turbine blades, exhaust nozzles, and combustion chambers.

- Satellite and Spacecraft Applications: Due to its dimensional stability in vacuum and high-radiation environments, 3J9 alloy is used in satellite framework and sensor supports.

- Semiconductor Equipment: Used in processing chambers, sensor enclosures, and precision mounts for semiconductor fabrication.

- Optical Instruments: The low expansion properties help maintain accuracy in telescopes, laser systems, and high-precision measurement devices.

- Heat-Resistant Fasteners: Applied in boilers, power plants, and high-temperature industrial systems, ensuring secure and long-lasting connections.

3J9 alloy is a high-performance iron-nickel alloy known for its superior strength, excellent thermal stability, and low expansion properties. Designed to meet the demanding requirements of automotive and aerospace engineering, 3J9 alloy rods provide outstanding mechanical performance, wear resistance, and corrosion resistance in extreme environments.

With the increasing need for lightweight, durable, and thermally stable materials, 3J9 alloy rods have become essential in high-precision engineering applications, where performance consistency and reliability are crucial.

Applications of 3J9 Alloy Rods

1. Automotive Engineering

The automotive industry requires materials that can withstand high temperatures, resist mechanical stress, and enhance fuel efficiency. 3J9 alloy rods are widely used in:

2. Aerospace Applications

In the aerospace industry, materials must perform reliably under extreme temperatures, pressure variations, and mechanical loads. 3J9 alloy rods are used in:

3. Precision Engineering and Industrial Applications

Beyond automotive and aerospace, 3J9 alloy rods find applications in high-precision manufacturing, including:

Key User Demands and Requirements

1. High-Temperature Resistance

In both automotive and aerospace applications, components must withstand extreme heat without deforming or losing strength. 3J9 alloy rods provide excellent oxidation and heat resistance, ensuring long-term reliability.

2. Dimensional Stability and Low Expansion

Aerospace and precision engineering industries require materials that do not expand or contract significantly with temperature changes. The low thermal expansion of 3J9 alloy rods ensures structural integrity in sensitive applications.

3. Corrosion and Wear Resistance

Automotive and aerospace parts are exposed to moisture, chemicals, and high-pressure environments. 3J9 alloy rods offer exceptional corrosion resistance, making them ideal for marine environments, aerospace components, and industrial machinery.

4. Lightweight yet High Strength

Reducing weight while maintaining high mechanical performance is a priority in both the automotive and aerospace industries. 3J9 alloy rods offer an optimal strength-to-weight ratio, improving fuel efficiency and structural integrity.

5. Compatibility with Advanced Manufacturing Techniques

3J9 alloy rods are highly adaptable to precision machining, CNC processing, and welding, making them suitable for complex engineering designs and custom components.

FAQs:

How long is the delivery time?

It depends on the quantity of the order, 10-30 days for small orders. For large orders, it takes 60 days.

Do you accept OEM/ODM production?

Yes! We accept OEM/ODM production. You can send us your samples or drawings.

How do you control the quality of your products? Do the chemical properties of the products meet the quality standards?

With professional quality team, advanced product quality planning, strict implementation and continuous improvement, we will issue product quality inspection certificate, including chemical analysis report.

Can your company provide detailed technical data and drawings?

Yes, you can. Please tell us the products and applications you need, and we will send you detailed technical data and drawings for your evaluation and confirmation.

How do you handle pre-sale and after-sale service?

We have a professional business team who will work one-on-one to protect your product needs, and if you have any questions, he can answer them for you!

Can I visit your factory before placing an order?

Yes, you are welcome to visit our factory. We are glad to have the opportunity to get to know each other.

Where is your production base?

We manufacture our products in Jiangsu, China and ship them from China to your country as soon as possible, which usually depends on your product requirements and quantity.

Can you send samples?

Yes, we can.